1. Intshayelelo

Iialloyi ze-aluminiyam ezinamandla aphakathi zibonisa iimpawu zokusetyenzwa ezincomekayo, ukucima ubuntununtunu, ukuqina kwempembelelo, kunye nokumelana nomhlwa. Baqeshwe kakhulu kumashishini ahlukeneyo, afana ne-electronics kunye ne-marine, ukwenza imibhobho, iirodi, iprofayili kunye neengcingo. Okwangoku, kukho imfuno ekhulayo yee-6082 ze-aluminium alloy bar. Ukuhlangabezana neemfuno zemarike kunye neemfuno zabasebenzisi, senze imifuniselo kwiinkqubo ezahlukeneyo zokufudumeza kwe-extrusion kunye neenkqubo zokugqibela zonyango lobushushu kwiibha ze-6082-T6. Injongo yethu yayikukuchonga irejimeni yonyango lobushushu eyanelisa iimfuno zokusebenza komatshini kule mivalo.

2.Izinto zoVavanyo kunye nokuPhuma kweNkqubo yeMveliso

2.1 Izixhobo zoMfuniselo

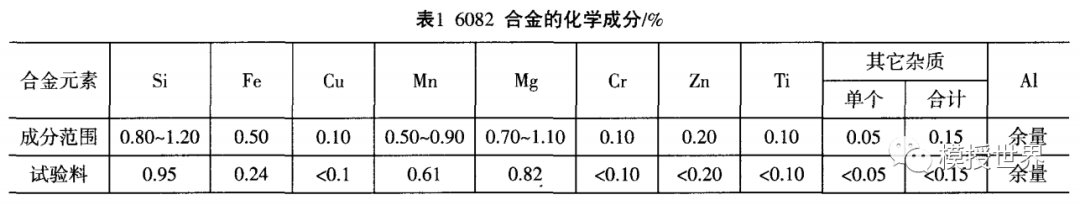

Ukuphoswa kwee-ingots zobukhulu be-Ф162 × 500 zaveliswa ngokusebenzisa indlela yokuphonswa kwe-semi-continuous kwaye ixhomekeke kunyango olungelulo. Umgangatho we-metallurgical we-ingots uhambelana nemigangatho yobugcisa yolawulo lwangaphakathi lwenkampani. Ukwakhiwa kweekhemikhali ze-alloy ye-6082 kuboniswe kwiThebhile 1.

2.2 UkuHamba kweNkqubo yeMveliso

Imivalo yovavanyo ye-6082 yayineenkcukacha zeФ14mm. Isitya sokukhupha sasinobubanzi be-Ф170mm kunye noyilo lwe-4-hole extrusion kunye ne-extrusion coefficient ye-18.5. Inkqubo ethile yokuhamba yayiquka ukufudumeza i-ingot, i-extrusion, ukucima, ukunweba ukulula kunye nesampuli, ukulungiswa kwe-roller, ukusika kokugqibela, ukuguga okwenziweyo, ukuhlolwa komgangatho kunye nokuhanjiswa.

3.IiNjongo zoMfuniselo

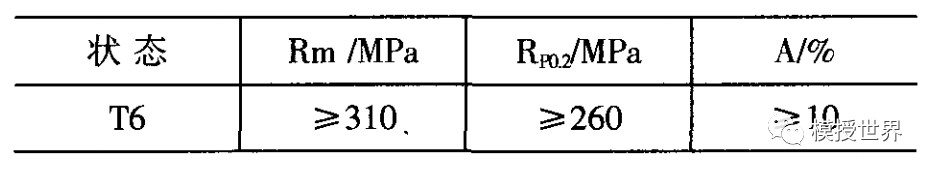

Injongo yolu phononongo yayikukuchonga iiparamitha zenkqubo yokushisa ubushushu obugqithisiweyo kunye neeparitha zokugqibela zonyango ezichaphazela ukusebenza kweebhari ze-6082-T6, ekugqibeleni zifezekise iimfuno ezisemgangathweni. Ngokwemigangatho, iipropati ze-longitudinal mechanical ze-alloy ye-6082 kufuneka zihlangabezane neenkcukacha ezidweliswe kwiThebhile 2.

4.Indlela yoVavanyo

4.1 UPhando loNyango loBubushushu obugqithisiweyo

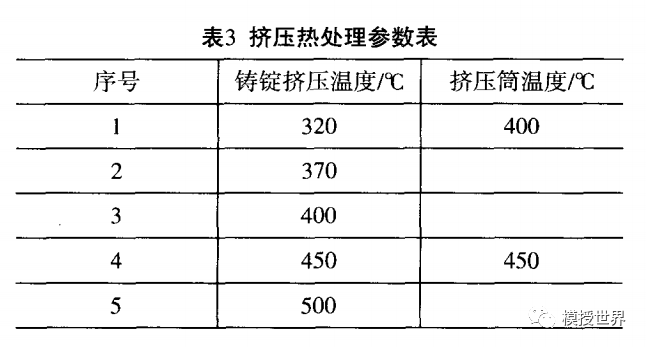

Uphando lwe-extrusion yonyango lobushushu lujolise ngokukodwa kwimiphumo yokuphosa i-ingot extrusion ubushushu kunye nobushushu besikhongozeli se-extrusion kwiipropati zomatshini. Ukhetho oluthile lweparameter luchazwe kwiThebhile 3.

4.2 Isisombululo esiSiqina kunye noPhando loNyango loBubushushu bokuguga

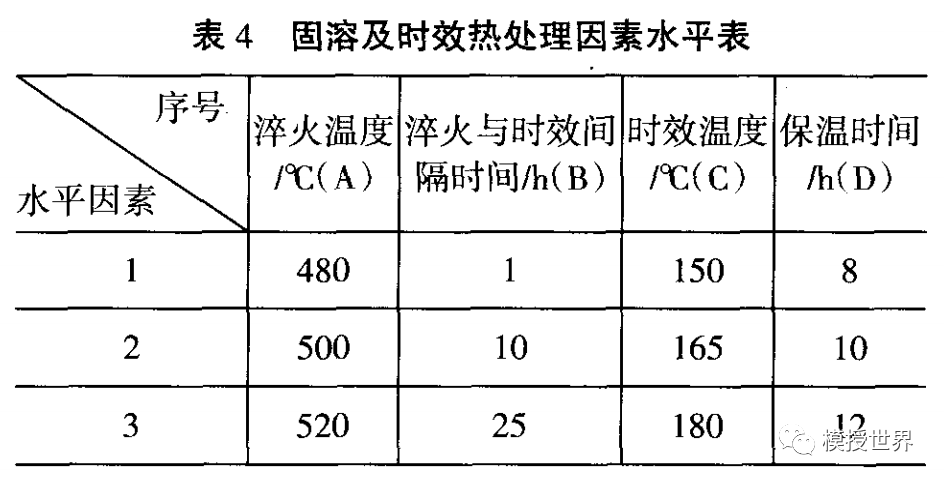

Uyilo lovavanyo lwe-orthogonal lwaqeshwa kwisisombululo esiluqilima kunye nenkqubo yonyango lobushushu obudala. Amanqanaba akhethiweyo anikwe kwiThebhile 4, kunye netafile yoyilo lwe-orthogonal echazwe njenge-IJ9(34).

5.Iziphumo kunye nohlalutyo

5.1 Iziphumo kunye noHlalutyo lokuNyangelwa koBubushushu boKwandiswa

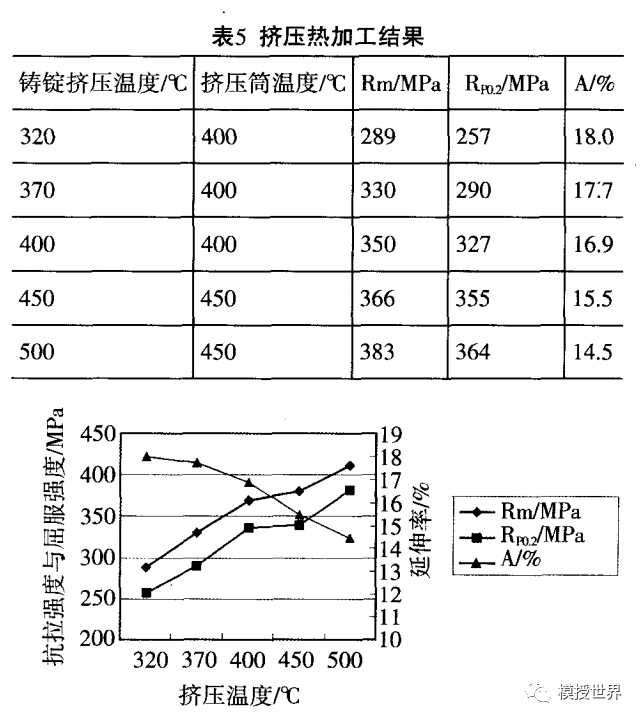

Iziphumo zovavanyo lonyango lwe-extrusion zinikezelwa kwiThebhile 5 kunye noMzobo 1. Iisampulu ezisithoba zithathwe kwiqela ngalinye, kwaye imilinganiselo yokusebenza komatshini inqunywe. Ngokusekelwe kuhlalutyo lwe-metallographic kunye nokubunjwa kweekhemikhali, irejimeni yonyango lokushisa yasekwa: ukucima kwi-520 ° C imizuzu engama-40 kunye nokuguga kwi-165 ° C kwiiyure ze-12. Ukusuka kwiTheyibhile yesi-5 kunye noMfanekiso 1, kunokuqatshelwa ukuba njengoko ubushushu be-ingot ye-extrusion yokuphosa kunye ne-extrusion ye-container ye-extrusion yonyuka, zombini amandla okuqina kunye namandla esivuno anyuka ngokuthe ngcembe. Iziphumo ezingcono zifunyenwe kumaqondo okushisa e-extrusion angama-450-500 ° C kunye neqondo lokushisa le-extrusion ye-extrusion ye-450 ° C, edibene neemfuno eziqhelekileyo. Oku kwakungenxa yesiphumo somsebenzi obandayo wokuqina kumaqondo obushushu asezantsi e-extrusion, okubangela ukuqhekeka komda weenkozo kunye nokunyuka kwesisombululo esiqinileyo sokubola phakathi kwe-A1 kunye ne-Mn ngexesha lokufudumeza ngaphambi kokucima, okukhokelela kwi-recrystallization. Njengoko ukushisa kwe-extrusion kwanda, amandla okugqibela e-Rm yemveliso aphuculwe kakhulu. Xa iqondo lobushushu lesikhongozeli se-extrusion lisondela okanye lidlule kwiqondo lobushushu le-ingot, ukuguqulwa okungalinganiyo kwancipha, ukunciphisa ubunzulu bamakhonkco okuziinkozo kunye nokwandisa amandla esivuno se-Rm. Ngoko ke, iiparameters ezifanelekileyo zokunyanga ubushushu be-extrusion zezi: ukushisa kwe-ingot extrusion ye-450-500 ° C kunye ne-extrusion ye-container ye-extrusion ye-430-450 ° C.

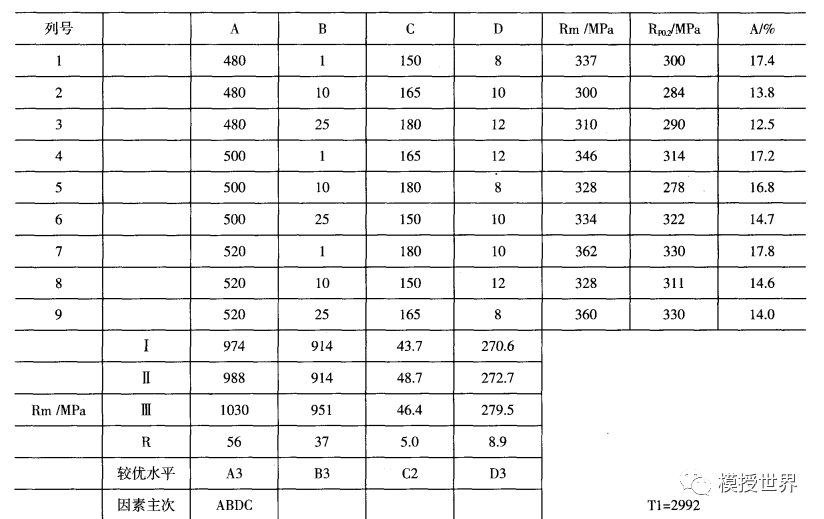

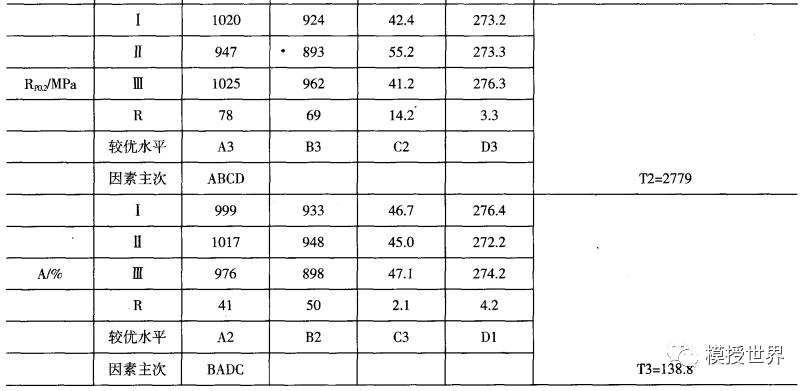

5.2 Isisombululo esiluqilima kunye nokuguga kwe-Orthogonal yeZiphumo zoMvavanyo kunye noHlalutyo

Itheyibhile 6 ibonisa ukuba amanqanaba afanelekileyo yi-A3B1C2D3, kunye nokucima kwi-520 ° C, ukushisa okuguga okwenziweyo phakathi kwe-165-170 ° C, kunye nokuguga kweeyure ze-12, okubangelwa amandla aphezulu kunye neeplastiki zemivalo. Inkqubo yokucima yenza isisombululo esiqinileyo se-supersaturated. Kwiqondo lokushisa eliphantsi lokucima, ukuxinwa kwesisombululo esiqinileyo se-supersaturated siyancipha, sichaphazela amandla. Ukushisa okucimayo okujikeleze i-520 ° C kwandisa kakhulu umphumo wokuqiniswa kwesisombululo esiluqilima. Ikhefu phakathi kokucima kunye nokuguga okwenziweyo, oko kukuthi, ukugcinwa kweqondo lokushisa kwegumbi, kuchaphazela kakhulu iipropati zomatshini. Oku kuchazwa ngokukodwa kwiintonga ezingolulwanga emva kokucinywa. Xa ikhefu phakathi kokucima kunye nokuguga lidlula iyure eli-1, amandla, ngokukodwa amandla okuvelisa, ayancipha kakhulu.

5.3 Uhlalutyo lweMetallographic Microstructure

Ukuphakama okuphezulu kunye nohlalutyo lwe-polarized lwenziwe kwimivalo ye-6082-T6 kwisisombululo esiqinileyo sokushisa kwe-520 ° C kunye ne-530 ° C. Iifoto zobukhulu obuphezulu zibonise imvula ehlanganisiweyo efanayo kunye namasuntswana amaninzi esigaba semvula esasazwe ngokulinganayo. Uhlalutyo lwe-polarized light usebenzisa izixhobo ze-Axiovert200 lubonise umahluko ocacileyo kwiifoto zesakhiwo senkozo. Ummandla osembindini ubonise iinkozo ezincinci kunye nezifanayo, ngelixa imiphetho ibonise ukuhlaziya kwakhona ngeenkozo ezinde. Oku kungenxa yokukhula kwekristale nuclei kumaqondo obushushu aphezulu, okwenza iirhashalala ezirhabaxa zenaliti.

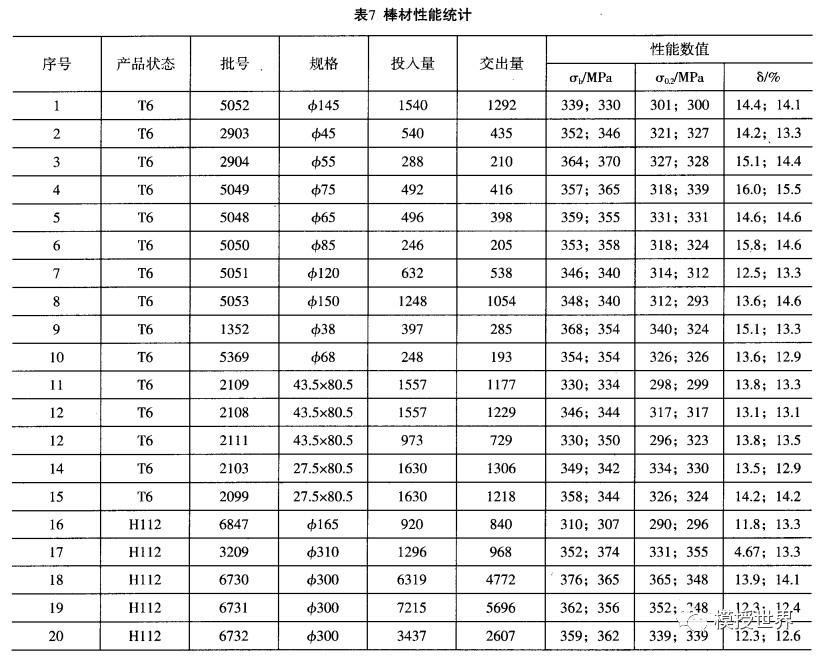

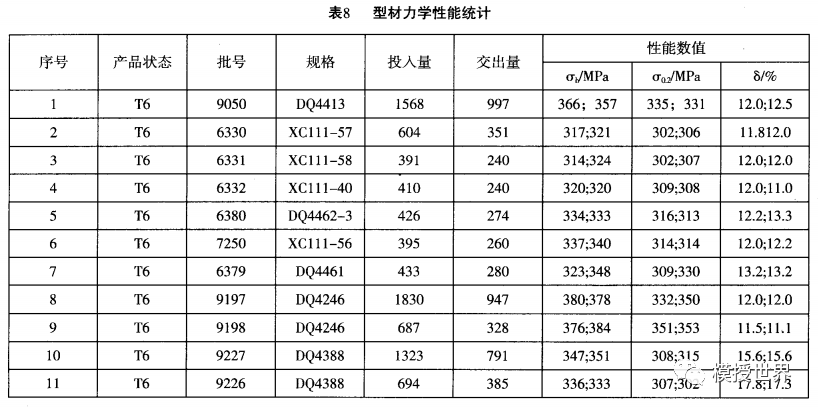

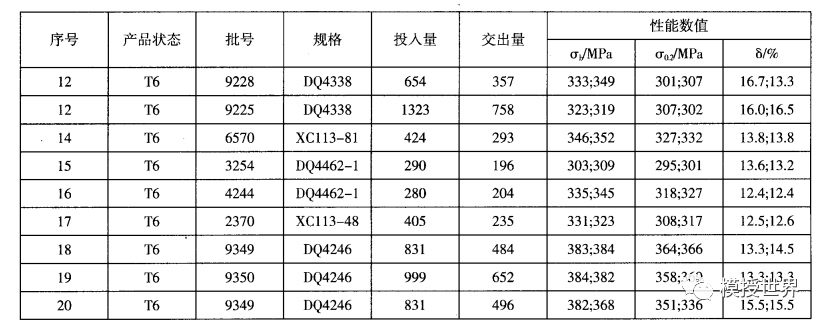

6.UVavanyo lokuSebenza kweMveliso

Kwimveliso eyiyo, izibalo zokusebenza ngoomatshini zaqhutywa kwiibhetshi ezingama-20 zemivalo kunye neebhetshi ezingama-20 zeeprofayili. Iziphumo ziboniswa kwiiThebhile 7 kunye ne-8. Kwimveliso yangempela, inkqubo yethu yokukhupha yenziwa kumaqondo okushisa okubangelwa iisampulu ze-T6, kwaye ukusebenza komatshini kudibene nemilinganiselo ekujoliswe kuyo.

7.Isiphelo

(1) Iiparamitha zokunyanga ukushisa kwe-Extrusion: I-ingots yokushisa kwe-extrusion ye-450-500 ° C; iqondo lobushushu lesikhongozeli se-extrusion ye-430-450°C.

(2) Iiparamitha zokugqibela zonyango lobushushu: Ubushushu obufanelekileyo besisombululo esiqinileyo se-520-530 ° C; ubushushu obudala kwi-165 ± 5 ° C, ukuguga ubude beeyure ze-12; ixesha eliphakathi kokucima kunye nokuguga akufanele lidlule iyure enye.

(3) Ngokusekelwe kuvavanyo olusebenzayo, inkqubo yokunyanga ukushisa okusebenzayo ibandakanya: ukushisa kwe-extrusion ye-450-530 ° C, ukushisa kwe-extrusion container ye-400-450 ° C; ubushushu besisombululo esiqinileyo se-510-520 ° C; irejimeni yokuguga ye-155-170 ° C kwiiyure ze-12; akukho mda ukhethekileyo kwisithuba phakathi kokucima kunye nokuguga. Oku kunokufakwa kwizikhokelo zokusebenza kwenkqubo.

Ihlelwe nguMay Jiang esuka kwiMAT Aluminium

Ixesha lokuposa: Mar-15-2024