Ukukhanya kweemoto yinjongo ekwabelwana ngayo kwishishini leemoto kwihlabathi jikelele. Ukwandisa ukusetyenziswa kwezixhobo ze-aluminium alloy kumacandelo eemoto yindlela yophuhliso lwezithuthi zanamhlanje. I-6082 i-aluminiyam i-alloy yi-aluminiyam ephathwayo, eyomeleziweyo ye-aluminium alloy enamandla aphakathi, ukubunjwa okugqwesileyo, ukuwelda, ukumelana nokudinwa, kunye nokuxhathisa ukubola. Le ngxubevange inokukhutshelwa kwimibhobho, iintonga, kunye neeprofayili, kwaye isetyenziswa ngokubanzi kumacandelo eemoto, iindawo ezidityanisiweyo zezakhiwo, ezothutho, kunye neshishini lokwakha.

Okwangoku, kukho uphando olulinganiselwe kwi-6082 ye-aluminium alloy ukuze isetyenziswe kwizithuthi zamandla amatsha e-China. Ke ngoko, olu phononongo lovavanyo luphanda iziphumo zoluhlu lwe-6082 ye-aluminium alloy element, iiparamitha zenkqubo ye-extrusion, iindlela zokucima, njl., kwiprofayili ye-alloy kunye ne-microstructure. Olu pho nonongo lujolise ekwandiseni ukubunjwa kwe-alloy kunye neeparitha zenkqubo ukuvelisa izinto ze-6082 ze-aluminium alloy ezifanelekileyo kwizithuthi zamandla amatsha.

1. Izinto zoVavanyo kunye neendlela

Ukuhamba kwenkqubo yovavanyo: I-alloy composition ratio - Ingot melting - Ingot homogenization - Ingot sawing kwiibhillet - Extrusion of profiles - In-line quenching of profiles - Artificial aging - Ukulungiswa kwemizekelo yovavanyo.

1.1 Ukulungiselela i-Ingot

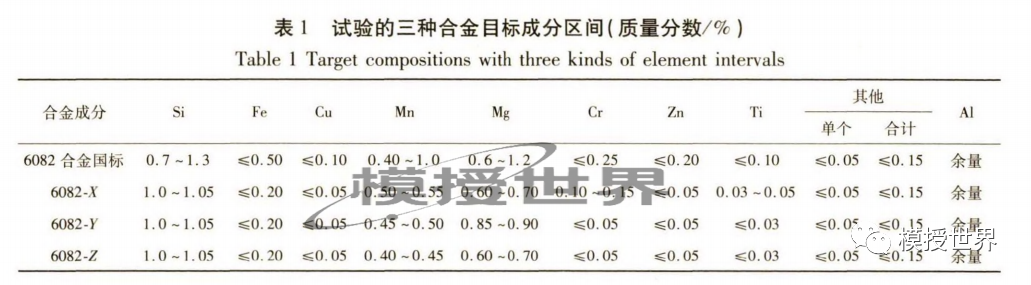

Ngaphakathi kuluhlu lwamazwe ngamazwe lwe-6082 ye-aluminium alloy compulments, iingoma ezintathu zakhethwa kunye noluhlu lolawulo oluncinci, olubhalwe njenge-6082-/6082", 6082-Z, kunye nomxholo weSi element. Umxholo wesiqalelo esinguMg, y > z; Mn isiqulatho sesiqalelo, x > y > z; Cr, Ti isiqulatho sesiqalelo, x > y = z. Amaxabiso ekujoliswe kuwo ekubunjweni kwe-alloy aboniswa kwiThebhile 1. Ukuchithwa kwe-ingot kwenziwa ngokusebenzisa indlela yokupholisa amanzi e-semi-cooling, elandelwa yi-homogenization yonyango. Zontathu ii-ingots zenziwa homogenized kusetyenziswa inkqubo esekiweyo yomzi-mveliso kuma-560°C kangangeeyure ezi-2 ngokupholisa inkungu yamanzi.

1.2 Ukwandiswa kweeProfayili

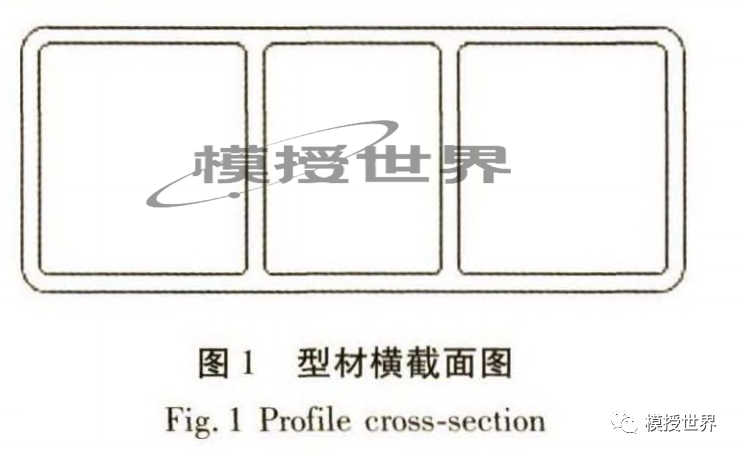

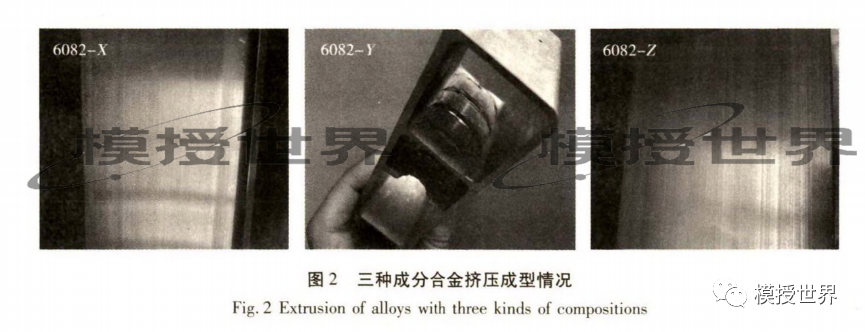

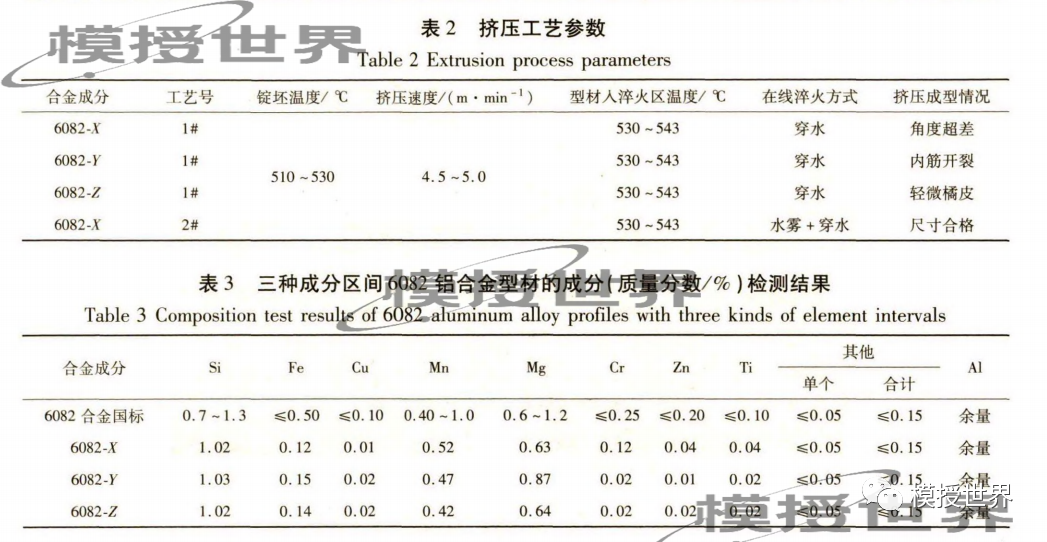

Iiparamitha zenkqubo ye-extrusion zahlengahlengiswa ngokufanelekileyo kwi-billet yokufudumeza ubushushu kunye nesantya sokupholisa sokucima. I-cross-section of profiles extruded iboniswe kwi-Figure 1. Iiparamitha zenkqubo ye-extrusion ziboniswa kwiThebhile 2. Isimo sokwenza iiprofayili ezigqithisiweyo ziboniswe kuMfanekiso 2.

2.Iziphumo zovavanyo kunye nohlalutyo

Ukubunjwa kweekhemikhali ezithile ze-6082 ye-aluminium alloy profiles ngaphakathi kweendlela ezintathu zokubunjwa kwagqitywa ngokusebenzisa i-Swiss ARL yokufunda i-spectrometer, njengoko kuboniswe kwiThebhile 3.

2.1 UVavanyo lweNtsebenzo

Ukuthelekisa, ukusebenza kweeprofayili ezintathu zoluhlu lwe-alloy kunye neendlela ezahlukeneyo zokucima, iiparamitha ze-extrusion ezifanayo, kunye neenkqubo zokuguga zihlolwe.

2.1.1 Ukusebenza koomatshini

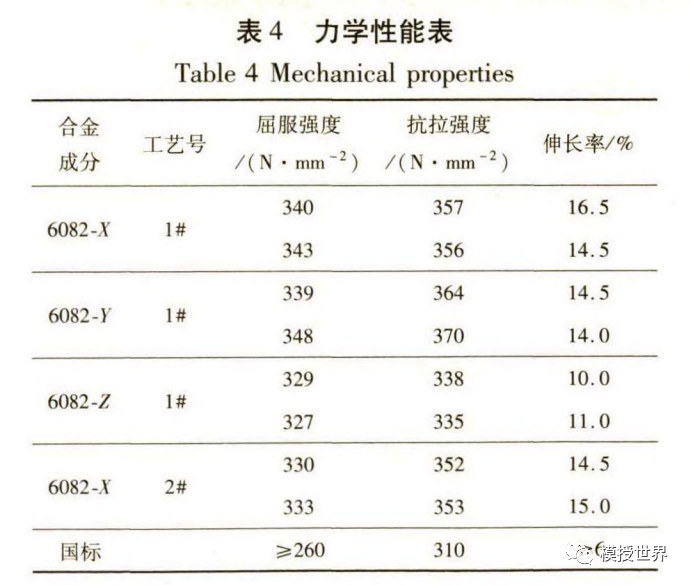

Emva kokuguga okwenziwa kwi-175 ° C kwiiyure ze-8, iisampuli eziqhelekileyo zithathwe kwicala lokukhutshwa kweeprofayili zokuvavanya i-tensile kusetyenziswa umatshini wokuvavanya we-elektroniki we-Shimadzu AG-X100. Ukusebenza komatshini emva kokuguga okwenziweyo kwiindidi ezahlukeneyo kunye neendlela zokucima kuboniswe kwiThebhile 4.

Ukususela kwiThebhile 4, kunokubonwa ukuba ukusebenza komatshini kuzo zonke iiprofayili kudlula amaxabiso asemgangathweni kazwelonke. Iiprofayili eziveliswe kwi-6082-Z i-alloy billets zine-elongation ephantsi emva kokuphuka. Iiprofayili eziveliswe kwiibhilithi ze-alloy ze-6082-7 zineyona ndlela iphezulu yokusebenza komatshini. Iiprofayili ze-6082-X ze-alloy, kunye neendlela ezahlukeneyo zesisombululo esiqinileyo, zibonise ukusebenza okuphezulu kunye neendlela zokucima ukupholisa ngokukhawuleza.

2.1.2 Ukugoba uVavanyo lokuSebenza

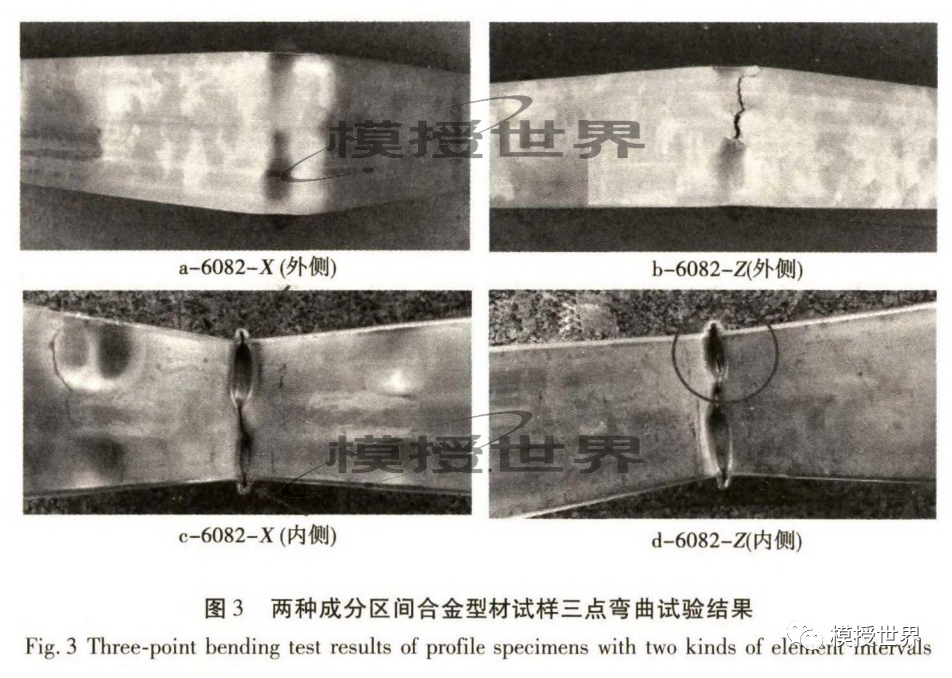

Ukusebenzisa umatshini wokuvavanya we-electronic universal, iimvavanyo zokugoba ezintathu zenziwa kwiisampuli, kwaye iziphumo zokugoba ziboniswe kuMzobo 3. Umzobo 3 ubonisa ukuba iimveliso eziveliswe kwi-6082-Z i-alloy billets zine-peel e-orange enzima phezu komhlaba kunye nokuqhekeka emva kweesampuli ezigobileyo. Iimveliso eziveliswe kwi-6082-X ye-alloy billets zinentsebenzo engcono yokugoba, iindawo ezigudileyo ngaphandle kwe-orenji ye-orenji, kunye nokuqhekeka okuncinci kuphela kwizikhundla ezilinganiselwe ngeemeko zejometri ngasemva kweesampuli ezigobileyo.

2.1.3 UHlolo olukwizinga eliphezulu

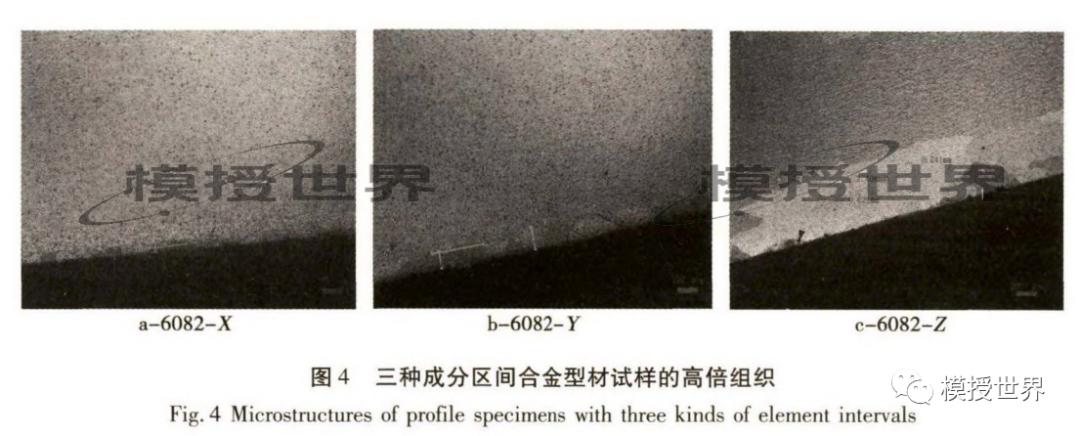

Iisampulu zabonwa phantsi kwe-microscope ye-Carl Zeiss AX10 yohlalutyo lwe-microstructure. Iziphumo zohlalutyo lwe-microstructure kwiiprofayili ezintathu zoluhlu lwe-alloy ziboniswe kwi-Figure 4. Umzobo we-4 ubonisa ukuba ubukhulu bengqolowa yeemveliso eziveliswe kwi-6082-X rod kunye ne-6082-K i-alloy billets yayifana, kunye nobukhulu bengqolowa obungcono kancinci kwi-6082-X i-alloy xa kuthelekiswa ne-6082-y alloy. Iimveliso eziveliswe ukusuka kwi-6082-Z iibhilithi zealloyi zazinobukhulu obuziinkozo obukhulu kunye neengqimba ezishinyeneyo ze-cortex, ezikhokelela ngokulula kumphezulu we-orenji yamaxolo kunye nokuncipha kokuhlangana kwesinyithi kwangaphakathi.

2.2 Uhlalutyo lweziphumo

Ngokusekwe kwezi ziphumo zovavanyo zingentla, kunokugqitywa ukuba uyilo loluhlu lwe-alloy composition luchaphazela kakhulu i-microstructure, ukusebenza, kunye nokwakheka kweeprofayili ezikhutshiweyo. Isiqulatho se-Mg esandisiweyo sinciphisa iplastiki ye-alloy kwaye ikhokelela ekubunjweni kokuqhekeka ngexesha lokukhupha. I-Higher Mn, Cr, kunye ne-Ti umxholo unefuthe elihle ekusulungekiseni i-microstructure, ethi yona ibe nefuthe elihle kumgangatho ophezulu, ukusebenza ngokugoba, kunye nokusebenza ngokubanzi.

3.Isiphelo

I-Mg element ichaphazela kakhulu ukusebenza komatshini we-6082 aluminium alloy. Umxholo owandisiweyo weMg unciphisa iplastiki ye-alloy kwaye ikhokelela ekubunjweni kokuqhekeka ngexesha lokukhupha.

UMn, Cr, kunye ne-Ti banefuthe elihle ekuphuculweni kwe-microstructure, ekhokelela kumgangatho ophuculweyo womphezulu kunye nokusebenza kokugoba kweemveliso ezikhutshiweyo.

Ukuqina okupholisa okuhlukeneyo kokucima kunempembelelo ebonakalayo ekusebenzeni kweeprofayili ze-6082 ze-aluminium alloy. Ukusetyenziswa kwemoto, ukwamkela inkqubo yokucima inkungu yamanzi elandelwa kukupholisa kwamanzi okutshiza kunika ukusebenza okungcono koomatshini kunye nokuqinisekisa ukumila kweeprofayili kunye nokuchaneka kobukhulu.

Ihlelwe nguMay Jiang esuka kwiMAT Aluminium

Ixesha lokuposa: Mar-26-2024