1. Iimpawu ze-aluminium kunye ne-aluminium ingxube ye-alloy ekhethekileyo ye-extrusion echanekileyo

Olu hlobo lwemveliso lunemilo ekhethekileyo, ubukhulu bodonga olubhityileyo, ubunzima beyunithi yokukhanya, kunye neemfuno ezingqongqo zokunyamezelana.Iimveliso ezinjalo zihlala zibizwa ngokuba yi-aluminium alloy precision (okanye i-ultra-precision) iiprofayili (imibhobho), kwaye iteknoloji yokuvelisa iimveliso ezinjalo ibizwa ngokuba ngokuchanekileyo.(okanye ultra-precision) extrusion.

Iimpawu eziphambili zealluminiyam ialloy echaneke ngokukodwa (okanye i-ultra-precision) i-extrusions zezi:

(1) Kukho iintlobo ezininzi, iibhetshi ezincinci, kwaye uninzi lwazo zizinto ezikhethekileyo zokukhupha, ezisetyenziswa phantse kuzo zonke iinkalo zobomi kunye neenkalo zonke zobomi babantu, kubandakanywa zonke iimveliso ze-extrusion, njengemibhobho, imivalo, iiprofayili. kunye neengcingo, ezibandakanya i-alloy eyahlukeneyo kunye nombuso.Ngenxa yecandelo elincinci lomnqamlezo, ubukhulu bodonga oluncinci, ubunzima obulula, kunye neebhetshi ezincinci, ngokuqhelekileyo akulula ukucwangcisa imveliso.

(2) Iimilo ezintsonkothileyo kunye neecontours ezikhethekileyo, ubukhulu becala obubunjiweyo, obumcaba, ububanzi, obunamaphiko, obunamazinyo, ubucwebe okanye imibhobho.Ummandla ongaphezulu kwiyunithi nganye umthamo omkhulu, kwaye iteknoloji yokuvelisa inzima.

(3) Ukusetyenziswa okubanzi, ukusebenza okukhethekileyo kunye neemfuno zokusebenza.Ukuze kuhlangatyezwane neemfuno zokusetyenziswa kwemveliso, iindawo ezininzi ze-alloy zikhethiwe, ezigubungela phantse zonke ii-alloys ukusuka kwi-1 × × × ukuya kwi-8 × × uchungechunge kunye namazwe amaninzi onyango, kunye nomxholo ophezulu wobugcisa.

(4) Inkangeleko egqwesileyo kunye nobukhulu bodonga olubhityileyo, ngokubanzi ngaphantsi kwe-0.5mm, abanye bade bafikelele malunga ne-0.1mm, ubunzima ngemitha nganye buziigram ezimbalwa ukuya kumashumi eegram, kodwa ubude bunokufikelela kwiimitha ezininzi, okanye namakhulu eemitha. .

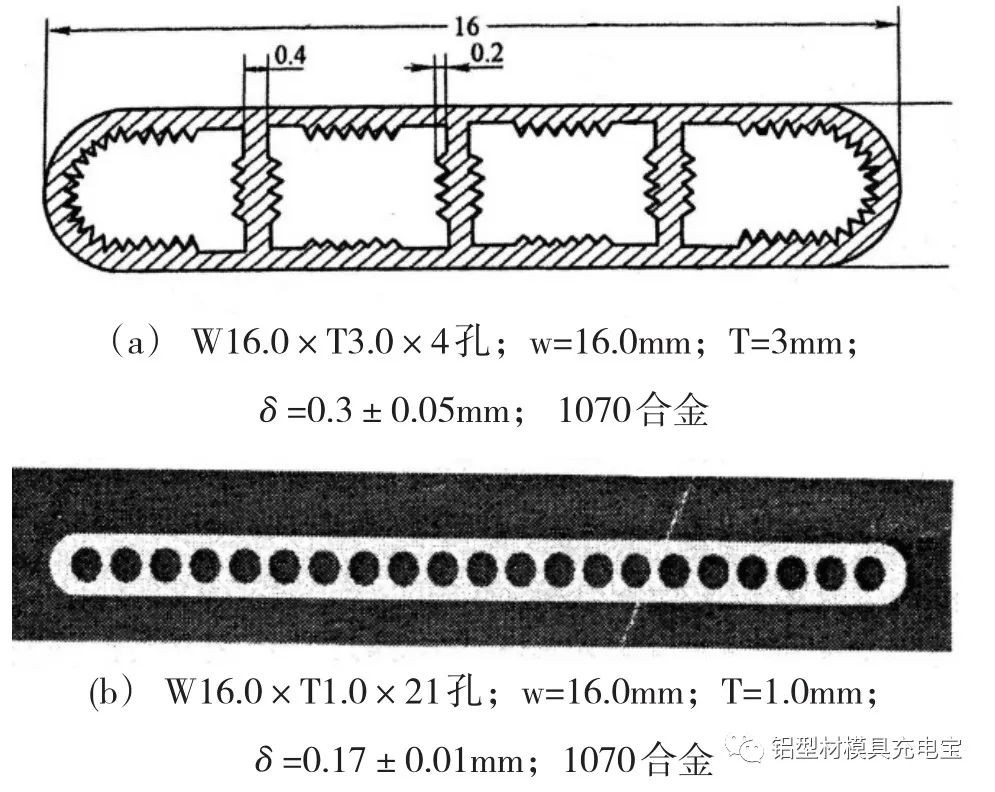

I-5) Ukuchaneka kwe-dimensional kunye neemfuno zokunyamezela kwejometri zecandelo zingqongqo kakhulu.Ngokuqhelekileyo, ukunyamezela kweeprofayili ezincinci ze-aluminium alloy ezichanekileyo ziphindwe kabini ngokungqongqo njengokunyamezela kwibakala elikhethekileyo kwi-JIS, i-GB, kunye nemigangatho ye-ASTM.Ukunyamezela kobunzima bodonga lweeprofayili zealluminiyam ezichanekileyo ezichanekileyo zifunekayo ukuba zibe phakathi kwe-± 0.04mm kunye ne-0.07mm, ngelixa ukunyamezela kwecandelo lokunyamezela kweeprofayili ze-aluminium alloy echanekileyo kunokuba phezulu njenge-± 0.01mm.Ngokomzekelo, ubunzima beprofayili ye-aluminium echanekileyo esetyenziselwa i-potentiometer yi-30g / m, kwaye uluhlu lokunyamezela kwecandelo lobungakanani ± 0.07mm.Ukunyamezela ubungakanani becandelo lomnqamlezo weeprofayili ezichanekileyo ze-aluminium kwi-looms yi-± 0.04mm, ukuphambuka kwe-angle kungaphantsi kwe-0.5 °, kunye ne-degree yokugoba yi-0.83 × L.Omnye umzekelo yi-tube ye-ultra-thin flat yemoto, enobubanzi obuyi-20mm, ubude obuyi-1.7mm, ubukhulu bodonga lwe-0.17±0.01mm, kunye nemingxuma engama-24, eyiprofayili ye-alloy ye-aluminium echanekileyo.

(6) Inomxholo ophezulu wobugcisa kwaye inzima kakhulu ukuyivelisa, kwaye ineemfuno ezikhethekileyo zezixhobo ze-extrusion, izixhobo, iibhilidi kunye neenkqubo zokuvelisa.Umzobo we-1 ngumzekelo wecandelo leeprofayili ezincinci ze-aluminium ezichanekileyo ezichanekileyo.

2. Ukuhlelwa kwe-aluminium alloy ekhethekileyo ye-extrusion ekhethekileyo

Ukuchaneka okanye i-ultra-precision ye-aluminium alloy extrusions isetyenziswa ngokubanzi kwizixhobo zombane, izixhobo zonxibelelwano kunye nesayensi yokusika, ukhuselo lwelizwe kunye noshishino lwezomkhosi, izixhobo ezichanekileyo zoomatshini, izixhobo zangoku ezibuthathaka, i-aerospace, ishishini lenyukliya, amandla kunye namandla, iinkwili kunye neenqanawa, iimoto kunye nezixhobo zothutho , izixhobo zonyango, izixhobo zehardware, izibane, ukufota kunye nezixhobo zombane.Ngokuqhelekileyo, ukuchaneka okanye i-ultra-precision aluminium alloy extrusions inokwahlulwa ibe ngamacandelo amabini ngokweempawu zabo zokubonakala: udidi lokuqala luyiprofayili kunye nemilinganiselo emincinci.Olu hlobo lweprofayile lukwabizwa ngokuba yi-ultra-encinci okanye i-mini-shape.Ubungakanani bayo bubonke budla ngokuba ziimilimitha ezimbalwa, ubuncinci bodonga lobuncinci bungaphantsi kwe-0.5mm, kwaye ubunzima beyunithi buziigremu ezininzi ukuya kumashumi eegram ngemitha nganye.Ngenxa yobukhulu bawo buncinci, ukunyamezelana okuqinileyo kudla ngokufuneka kubo.Ngokomzekelo, ukunyamezela kwemilinganiselo ye-cross-sectional ingaphantsi kwe-± 0.05mm.Ukongeza, iimfuno zokuthi tye kunye ne-torsion yeemveliso ezikhutshiweyo nazo zingqongqo kakhulu.

Olunye uhlobo ziiprofayili ezingencinci kakhulu kubungakanani becandelo elinqamlezayo kodwa zifuna ukunyamezela okungqongqo kakhulu, okanye iiprofayili ezinemilo entsonkothileyo yecandelo kunye nobukhulu bodonga olubhityileyo nangona ubungakanani becandelo lomnqamlezo bukhulu.Umzobo we-2 ubonisa ityhubhu ekhethekileyo (i-aluminium ecocekileyo ye-industrial) ekhutshwe yinkampani yaseJapan kwi-16.3MN ye-horizontal hydraulic press kunye ne-difa ekhethekileyo yokwahlula kwi-condenser ye-automotive air-conditioning.Ubunzima bokwenza i-extrusion yolu hlobo lweprofayili ayikho ngaphantsi kohlobo lwangaphambili lwe-ultra-small profile.Iiprofayili ezongeziweyo ezinobungakanani becandelo elikhulu kunye neemfuno zonyamezelo ezingqongqo azidingi nje itekhnoloji yoyilo oluphezulu lokungunda, kodwa zifuna itekhnoloji yolawulo olungqongqo kuyo yonke inkqubo yokuvelisa ukusuka kwimveliso engenanto ukuya kwimveliso egqityiweyo.

Ukususela ekuqaleni kwee-1980s, ngenxa yokusetyenziswa okusebenzayo kwe-Conform continuous extrusion technology kunye nophuhliso lobuchwepheshe bemizi-mveliso, ukukhutshwa kweeprofayili ezincinci kunye ne-ultra-small ziphuhliswe ngokukhawuleza.Nangona kunjalo, ngenxa yezizathu ezahlukeneyo ezifana nokunciphisa izixhobo, iimfuno zomgangatho wemveliso, kunye nokuhambela phambili kubuchwepheshe be-extrusion, ukuveliswa kweeprofayili ezincinci kwisixhobo esiqhelekileyo se-extrusion kusabala umlinganiselo omkhulu.Umzobo we-2 ubonisa iiprofayili ezichanekileyo ze-extrusion yokwahlukana okuqhelekileyo kuyafa.Ubomi besikhunta (ngokukodwa amandla kunye nokuxhatshazwa kokugqoka kwebhulorho ye-shunt kunye ne-mold core) kunye nokuhamba kwezinto eziphathekayo ngexesha lokukhupha kube yimiba ephambili echaphazela imveliso yayo.Oku kungenxa yokuba xa extruding iprofayile, ubungakanani core ngundo incinci kwaye imilo entsonkothileyo, kwaye amandla kunye nokumelana banxibe izinto ezibalulekileyo ezichaphazela ubomi ngundo, ubomi ngundo kuchaphazela ngqo iindleko imveliso.Ngakolunye uhlangothi, iiprofayili ezininzi ezichanekileyo zineendonga ezincinci kunye neemilo eziyinkimbinkimbi, kwaye ukuhamba kwezinto ngexesha lenkqubo ye-extrusion kuchaphazela ngokuthe ngqo ubume kunye nokuchaneka kwe-dimensional yeeprofayili.

Ukuze uthintele ifilimu ye-oxide kunye neoli ebusweni be-billet ukuba ingaphumi kwimveliso kwaye iqinisekise umgangatho ofanayo kunye nomgangatho othembekileyo wemveliso, i-billet eshushu kwiqondo lokushisa elibekiweyo inokuhlanjululwa ngaphambi kokuba i-extrusion (ebizwa ngokuba yi-hot peeling), kwaye emva koko ngokukhawuleza ufake kwi-barrel ye-extrusion ye-extrusion.Ngelo xesha, i-gasket ekhutshiweyo kufuneka igcinwe icocekile ukukhusela ioli kunye nokungcola ekubambeleleni kwi-gasket ngexesha lenkqubo yokukhupha uxinzelelo olugqithisiweyo emva kokukhutshwa kunye nokufaka i-gasket kwi-extrusion elandelayo.

Ngokwecandelo lokuchaneka kwe-dimensional kunye nokuma kunye nokunyamezela isikhundla, i-extrusion ekhethekileyo ye-aluminium alloy extrusion inokwahlulwa ibe yiprofayili ekhethekileyo ye-aluminium echanekileyo echanekileyo kunye neeprofayili ezincinci (ezincinci) ze-ultra-high ezichanekileyo ze-aluminium alloy.Ngokubanzi, ukuchaneka kwayo kudlula umgangatho wesizwe (njenge-GB, i-JIS, i-ASTM, njl. njl.) Ukuchaneka kwe-ultra-high kubizwa ngokuba yiprofayili ekhethekileyo ye-aluminium alloy echanekileyo, umzekelo, ukunyamezela kwe-dimensional kungaphezulu kwe-± 0.1mm, ukunyamezela kobunzima bodonga umphezulu owaphukileyo ungaphakathi ± 0.05mm ~ ± 0.03mm iiprofayili nemibhobho.

Xa ukuchaneka kwayo kungaphezulu kokuphindwe kabini komgangatho wesizwe wokuchaneka kwe-ultra-high, ibizwa ngokuba yincinci (incinci) iprofayili ye-aluminium echanekileyo ephezulu, efana nokunyamezela imilo ye-± 0.09mm, ukunyamezela kobunzima be-± 0.03mm ~ ± 0.01mm kwiprofayili encinci (encinci) okanye umbhobho.

3. Amathuba okuphuhlisa i-aluminium kunye ne-aluminium alloy i-alloy ekhethekileyo ye-extrusion echanekileyo

Ngo-2017, ukuveliswa kunye nokuthengiswa kwezixhobo zokulungisa i-aluminium emhlabeni kudlula i-6000kt / a, apho imveliso kunye neentengiso ze-aluminiyam kunye ne-aluminiyam i-alloy extrusion imathiriyeli idlula i-25000kt / a, ibalwa ngaphezu kwe-40% yemveliso epheleleyo kunye neentengiso ze aluminiyam.Aluminiyam extruded imivalo medium kubalwe 90%, apho iinkangeleko jikelele kunye nemivalo kunye neeprofayile zokwakha ezincinane kunye nobukhulu obuphakathi babalelwa ngaphezulu kwe 80% ye bar, iiprofayili ezinkulu kunye nobungakanani obuphakathi kunye neeprofayili ezizodwa ezizodwa kunye nemivalo babalelwa kuphela malunga. 15%.I-akhawunti yombhobho malunga ne-8% ye-aluminium alloy extruded material, ngelixa umbhobho owenziweyo kunye ne-akhawunti ekhethekileyo yombhobho kuphela malunga ne-20% yombhobho.Kunokubonwa apha ngasentla ukuba eyona mveliso inkulu kunye neentengiso ze-aluminiyam kunye ne-aluminiyam i-alloy extrusion materials kunye nezona zisetyenziswa kakhulu zincinci kunye neeprofayili zokwakha uluntu, iiprofayili ngokubanzi kunye nemivalo kunye nemibhobho.Kwaye iiprofayili ezikhethekileyo, imivalo kunye nemibhobho kuphela i-akhawunti malunga ne-15%, iimpawu eziphambili zeemveliso ezinjalo: kunye nemisebenzi ekhethekileyo okanye ukusebenza;Inikezelwe kwinjongo ethile;Ukuba nesayizi enkulu okanye encinci yenkcazo;Ngokuchaneka okuphezulu kakhulu komgangatho okanye iimfuno zomphezulu.Ngoko ke, iindidi ezininzi kwaye i-batch incinci, imfuneko yokwandisa iinkqubo ezikhethekileyo okanye ukongeza ezinye izixhobo ezikhethekileyo kunye nezixhobo, imveliso inzima kwaye umxholo wezobugcisa uphezulu, iindleko zokuvelisa zanda kwaye ixabiso elongezelelweyo liyanda.

Ngenkqubela phambili yesayensi kunye nobuchwepheshe kunye nokuphuculwa okuqhubekayo kwemigangatho yokuphila kwabantu, iimfuno eziphezulu kunye eziphezulu ziye zabekwa phambili kwimveliso, umgangatho kunye neentlobo ezahlukeneyo ze-aluminium kunye ne-aluminium i-alloy extrusion yeemveliso, ngakumbi kwiminyaka yakutshanje, ukuvela kwemveliso yobuntu. ikhuthaze uphuhliso lweeprofayili ezikhethekileyo kunye nemibhobho eneempawu zomntu kunye nokusetyenziswa okuthe ngqo.

Iiprofayili ezichanekileyo zisetyenziswa ngokubanzi kwizixhobo ze-elektroniki, unxibelelwano, iposi kunye nezixhobo zonxibelelwano, oomatshini bokuchaneka, izixhobo ezichanekileyo, izixhobo zangoku ezibuthathaka, i-aerospace, iinkwili zenyukliya kunye neenqanawa, ishishini lemoto kunye nezinye iindawo zodonga oluncinci, olubhityileyo, ubukhulu becandelo iindawo ezichanekileyo.Ngokuqhelekileyo iimfuno zokunyamezela zingqongqo kakhulu, umzekelo, ukunyamezela ubungakanani becandelo lecandelo lingaphantsi kwe-± 0.10mm, ukunyamezela kodonga lungaphantsi kwe-± 0.05mm.Ukongeza, i-flatness, ukujija kunye nezinye iifom kunye nokunyamezela isikhundla seemveliso ezikhutshiweyo nazo zingqongqo kakhulu.Ukongeza, kwinkqubo ye-extrusion yeeprofayili zealluminiyam ezikhethekileyo ezincinci ze-ultra-precision, izixhobo, i-mold, inkqubo iyimfuno engqongqo kakhulu.Ngenxa yophuhliso olukhawulezayo loshishino lwanamhlanje, ukhuselo lwelizwe oluphambili kunye nophando lwezenzululwazi kunye nezinye izinto ezenziwayo kunye nokuphuculwa kwenqanaba lomntu, inani, iintlobo kunye nomgangatho weeprofayili ezincinci ezichanekileyo zisanda phezulu, nangona kwiminyaka yakutshanje, iphuhlise kwaye ivelise uninzi lweeprofayili zealloyi ezichanekileyo ezikumgangatho ophezulu, kodwa azikwazi ukuhlangabezana neemfuno zemarike, ngokukodwa, kusekho umsantsa omkhulu phakathi kobuchwepheshe basekhaya kunye nezixhobo zokuvelisa i-ultra encinci. -Iiprofayili ezichanekileyo ze-aluminium alloy kunye nenqanaba eliphezulu lamazwe ngamazwe, elingenako ukuhlangabezana neemfuno zemarike yasekhaya nangaphandle kwaye kufuneka ibanjwe.

4. Isiphelo

I-aluminiyam kunye ne-aluminiyam i-alloy ye-alloy extrusion ekhethekileyo (iiprofayili kunye nemibhobho) luhlobo lwemilo entsonkothileyo, ubukhulu bodonga olubhityileyo, ukunyamezelana kwedimensional kunye nemilo kunye neemfuno zokuchaneka kwesikhundla zifuna kakhulu, umxholo ophezulu wobugcisa, imveliso enzima ephezulu, imveliso emihle, yelizwe lonke. uqoqosho kunye nokhuselo lwesizwe izinto eziphambili eziyimfuneko, uluhlu olubanzi kakhulu losetyenziso, ithemba lophuhliso lwezinto eziphathekayo.Imveliso yale mveliso ineemfuno ezikhethekileyo ze-billet, izixhobo kunye nezixhobo ze-extrusion kunye nenkqubo ye-extrusion, kunye noluhlu lweengxaki eziphambili zobugcisa kufuneka zisonjululwe ukuze kufumaneke iimveliso ezigqwesileyo kwiibhetshi.

Ihlelwe nguMay Jiang esuka kwiMAT Aluminium

Ixesha lokuposa: Apr-07-2024