I-Aluminiyam yinto eqhelekileyo ekhankanyiweyo ye-extrusion kunye neeprofayili zemilo kuba ineempawu zomatshini ezenza ukuba zilungele ukwenza kunye nokubumba isinyithi ukusuka kumacandelo e-billet. I-ductility ephezulu ye-aluminium ithetha ukuba isinyithi sinokubunjwa ngokulula kwiindidi ezinqamlezileyo ngaphandle kokuchitha amandla amaninzi kwi-machining okanye inkqubo yokwenza, kwaye i-aluminium nayo ineendawo zokunyibilika malunga nesiqingatha sentsimbi eqhelekileyo. Zombini ezi nyaniso zithetha ukuba inkqubo yeprofayili ye-aluminium ye-extrusion inamandla aphantsi, okunciphisa izixhobo zokusebenza kunye neendleko zokuvelisa. Okokugqibela, i-aluminiyam nayo inamandla aphezulu kumlinganiselo wobunzima, iyenza ibe lolona khetho lubalaseleyo kwizicelo zamashishini.

Njengeproduct yenkqubo ye-extrusion, ilungile, imigca ephantse ingabonakali ngamanye amaxesha inokuvela kumphezulu weprofayili. Oku kubangelwa ukubunjwa kwezixhobo ezincedisayo ngexesha lokukhupha, kwaye unyango olongezelelweyo lomphezulu lunokucaciswa ukususa le migca. Ukuphucula ukugqitywa komphezulu wecandelo leprofayili, imisebenzi emininzi yonyango yendawo yesibini efana nokugaya ubuso inokwenziwa emva kwenkqubo ephambili yokwenza i-extrusion. Le misebenzi yomatshini ingacaciswa ukuphucula ijometri yomhlaba ukuphucula iprofayili yenxalenye ngokunciphisa ubuninzi bomphezulu weprofayili ekhutshiweyo. Olu nyango luhlala lucaciswa kwizicelo apho ukubekwa okuchanekileyo kwendawo kuyadingeka okanye apho iindawo zokukhwelana kufuneka zilawulwe ngokuqinileyo.

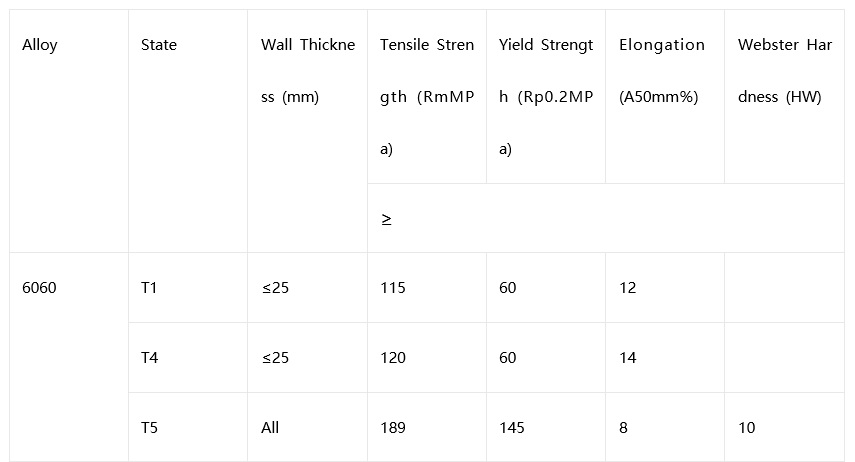

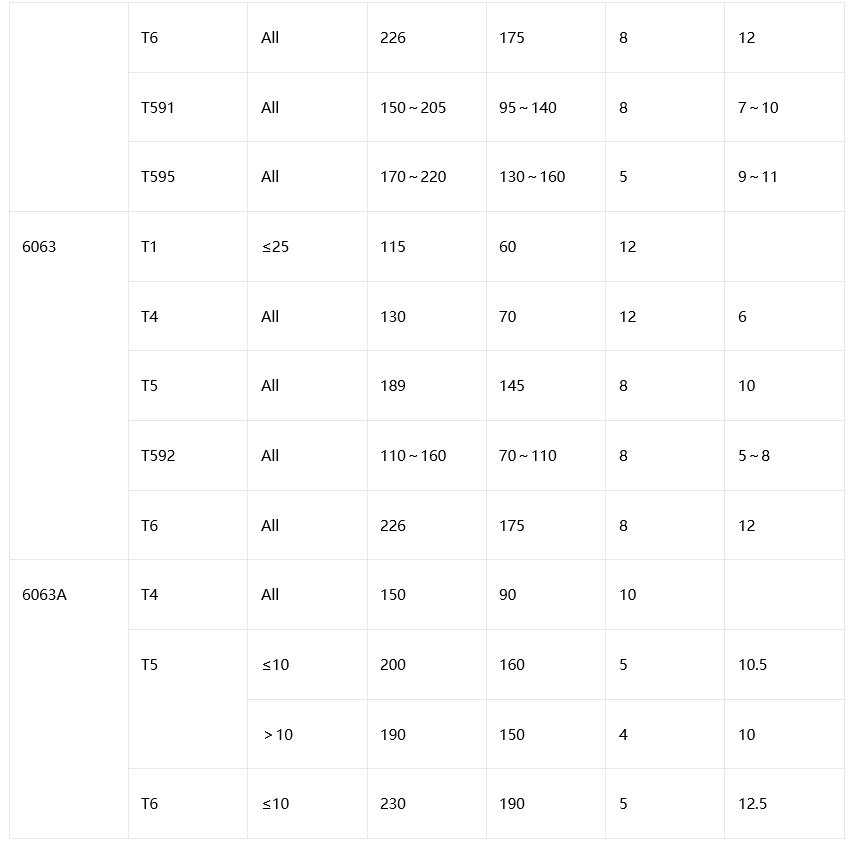

Sisoloko sibona ikholamu yezinto eziphawulwe nge-6063-T5 / T6 okanye 6061-T4, njl njl. I-6063 okanye i-6061 kule nqaku yi-brand yeprofayili ye-aluminium, kunye ne-T4 / T5 / T6 yimeko yeprofayili ye-aluminium. Ngoko ke yintoni umahluko phakathi kwabo?

Umzekelo: Ukubeka nje, iprofayili ye-6061 ye-aluminium inamandla angcono kunye nokusebenza kokusika, kunye nokuqina okuphezulu, i-weldability efanelekileyo kunye nokumelana nokubola; Iprofayile ye-6063 ye-aluminium ineplastiki engcono, enokwenza ukuba izinto eziphathekayo zifezekiseke ngokuchaneka okuphezulu, kwaye kwangaxeshanye zinamandla aphezulu okuqina kunye nokuqina kwesivuno, zibonisa ukomelela okungcono kokuqhekeka, kwaye unamandla aphezulu, ukuxhathisa ukunxiba, ukuxhathisa ukubola kunye nokumelana nobushushu obuphezulu.

T4 ithi:

unyango lwesisombululo + ukuguga kwendalo, oko kukuthi, iprofayili ye-aluminium ipholile emva kokuba ikhutshwe kwi-extruder, kodwa ingagugi kwiziko lokuguga. Iprofayili ye-aluminiyam engekagugi inobunzima obuphantsi kunye nokukhubazeka okulungileyo, okufanelekile ukugoba kamva kunye nolunye uhlengahlengiso.

T5 imeko:

unyango isisombululo + ukungapheleli ukuguga yokwenziwa, oko kukuthi, emva kokupholisa umoya ukucima emva extrusion, kwaye emva koko idluliselwe eziko ukuguga ukugcina ubushushu malunga 200 degrees iiyure 2-3. I-aluminiyam kweli lizwe inobunzima obuphezulu kunye neqondo elithile lokukhubazeka. Yeyona nto isetyenziswa ngokuqhelekileyo kwiindonga zamakhethini.

T6 imeko:

unyango isisombululo + ukuguga okupheleleyo eyenziweyo, oko kukuthi, emva kokupholisa amanzi ukucima emva extrusion, ukuguga eyenziweyo emva ukucima liphezulu T5 lobushushu, kwaye ixesha lokugquma kwakhona ixesha elide, ukuze kuzuzwe ubulukhuni ubume obuphezulu, nto leyo ifanelekile kwizihlandlo ezineemfuno eziphezulu kakhulu zobunzima bezinto eziphathekayo.

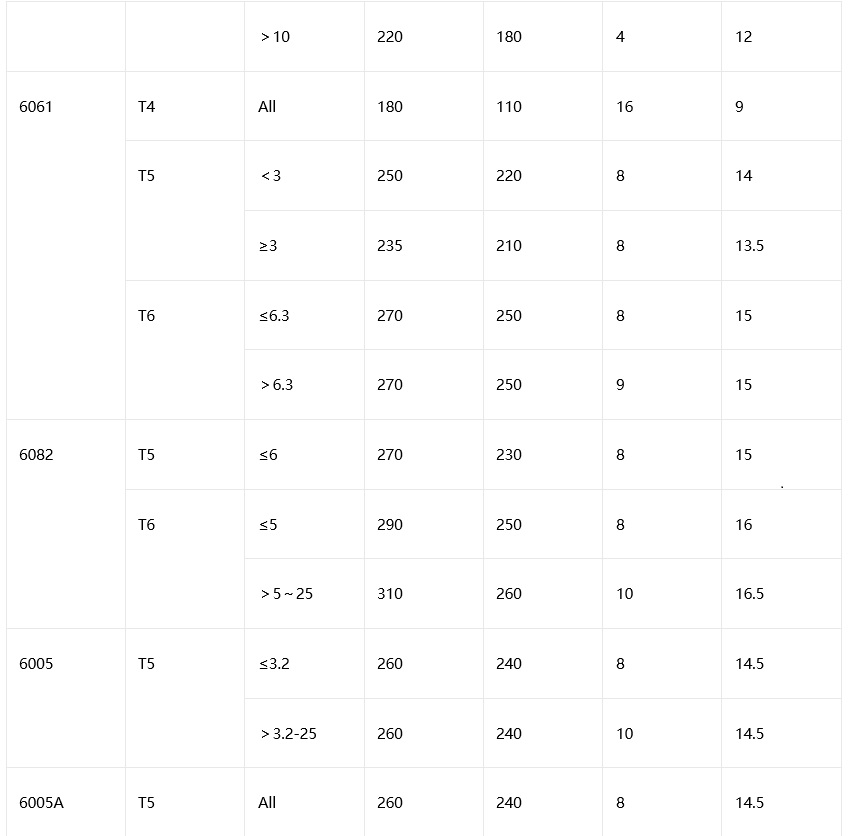

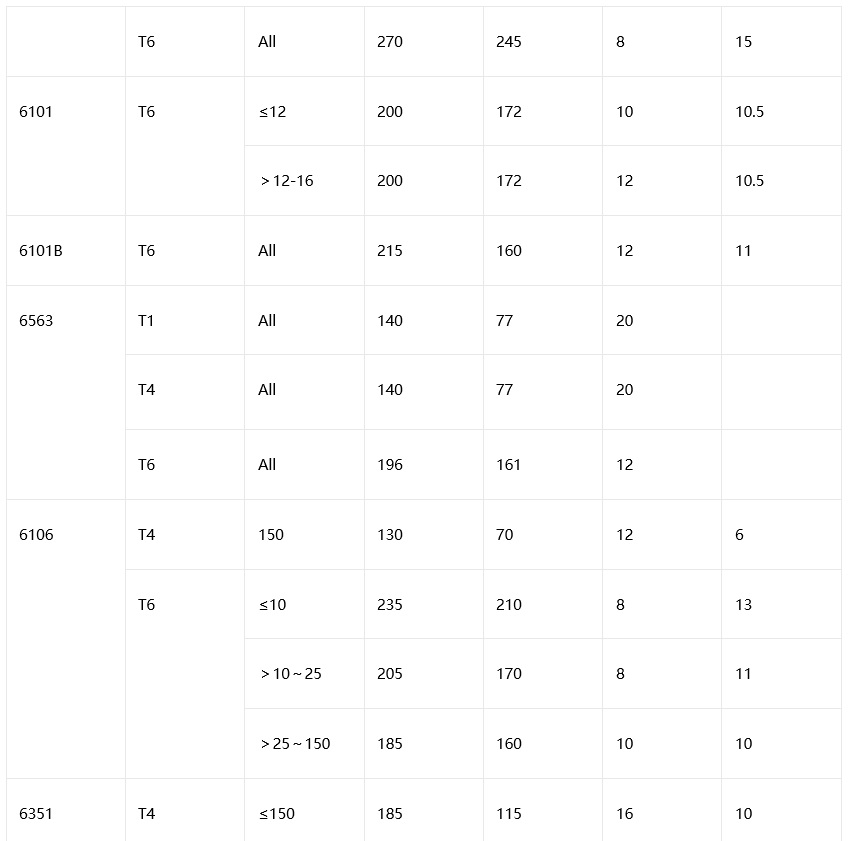

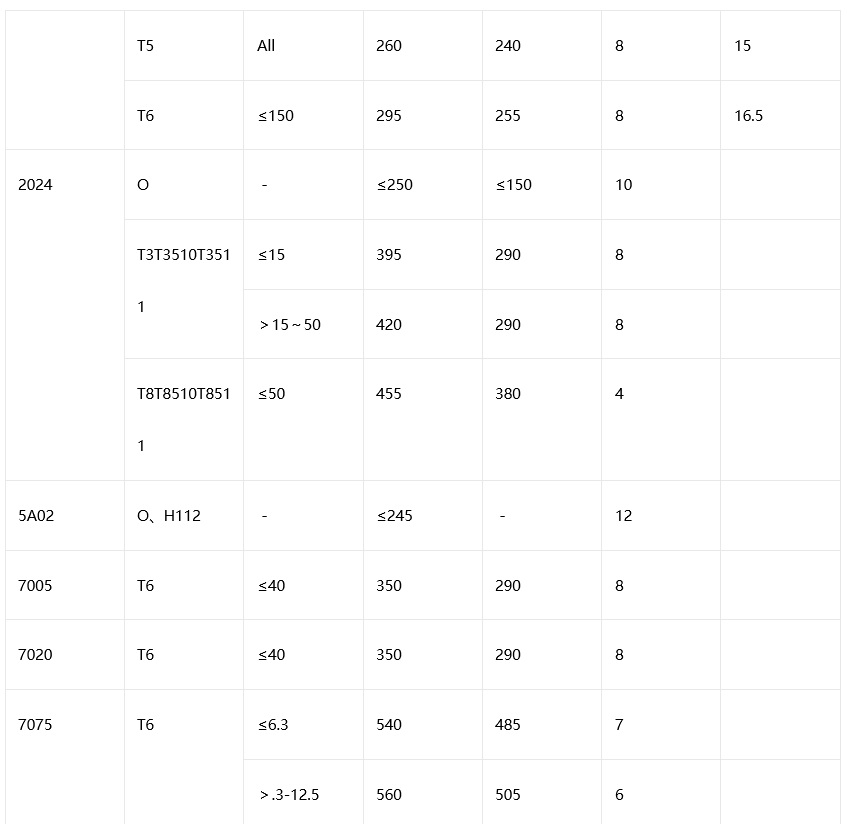

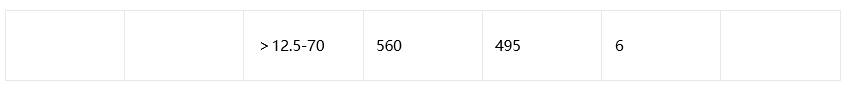

Iipropathi zomatshini zeeprofayili ze-aluminium zezixhobo ezahlukeneyo kunye namazwe ahlukeneyo achazwe kwitheyibhile engezantsi:

Unikeze Amandla:

Ngumda wesivuno sezinto zetsimbi xa zivelisa, oko kukuthi, uxinzelelo oluchasayo ukuguqulwa kweplastiki encinci. Kwizinto zetsimbi ngaphandle kwesivuno esicacileyo, ixabiso loxinzelelo oluvelisa i-0.2% ye-deformation eseleyo ichazwe njengomda wayo wesivuno, obizwa ngokuba ngumda wesivuno esinemiqathango okanye amandla okuvelisa. Amandla angaphandle amakhulu kunomda ayakubangela ukuba iinxalenye zingaphumeleli ngokusisigxina kwaye azikwazi ukubuyiselwa.

Tensile strength:

Xa i-aluminium ivelisa kwinqanaba elithile, ukukwazi ukumelana nokuguqulwa kwanda kwakhona ngenxa yokulungiswa kwakhona kweenkozo zangaphakathi. Nangona i-deformation ikhula ngokukhawuleza ngeli xesha, inokunyuka kuphela ngokunyuka koxinzelelo kuze kube yilapho uxinzelelo lufikelela kwixabiso eliphezulu. Emva koko, ukukwazi kweprofayili ukumelana nokuguqulwa kuncitshiswe kakhulu, kwaye i-deformation enkulu yeplastiki yenzeke kwindawo ebuthathaka. I-cross-section of the specimen apha iyancipha ngokukhawuleza, kwaye intamo yenzeke ide iphule.

Ukuqina kweWebster:

Umgaqo osisiseko wobulukhuni beWebster kukusebenzisa inaliti yoxinzelelo ecinyiweyo yesimo esithile ukucinezela kumphezulu wesampuli phantsi kwamandla omthombo oqhelekileyo, kwaye uchaze ubunzulu be-0.01MM njengeyunithi yobulukhuni beWebster. Ubunzima bezinto eziphathekayo buhambelana ngokuphambene nobunzulu bokungena. Okukhona ungenzulu kakhulu ukungena, kokukhona buphakama ubulukhuni, kwaye ngokuphambanayo.

Ukuguqulwa kwePlastiki:

Olu luhlobo lokuguqulwa olungenakukwazi ukuzibuyisela. Xa izinto zobunjineli kunye namacandelo zilayishwa ngaphaya koluhlu lwe-elastic deformation, i-deformation esisigxina iya kwenzeka, oko kukuthi, emva kokuba umthwalo ususiwe, ukuguqulwa okungaguqukiyo okanye ukuguqulwa okushiyekileyo kuya kwenzeka, okuyi-deformation yeplastiki.

Ixesha lokuposa: Oct-09-2024