I-6063 aluminium ingxubevange yeye-alloyed ephantsi ye-Al-Mg-Si uthotho lwe-aluminiyam olunyangwa ngobushushu. Inomsebenzi ogqwesileyo wokubumba we-extrusion, ukuxhathisa okulungileyo kwe-corrosion kunye neempawu zoomatshini ezibanzi. Ikwasetyenziswa kakhulu kwishishini leemoto ngenxa yombala wayo olula we-oxidation. Ngokukhawuleza kwendlela yeemoto ezikhaphukhaphu, ukusetyenziswa kwe6063 aluminium alloy extrusion imathiriyeli kushishino lweemoto kuye kwanda ngakumbi.

I-microstructure kunye neepropati zezinto ezikhutshiweyo zichaphazeleka kwimiphumo edibeneyo yesantya se-extrusion, ukushisa kwe-extrusion kunye ne-extrusion ratio. Phakathi kwabo, umlinganiselo we-extrusion unqunywe ngokukodwa ngoxinzelelo lwe-extrusion, ukusebenza kakuhle kwemveliso kunye nezixhobo zokuvelisa. Xa i-extrusion ratio incinci, i-alloy deformation incinci kwaye ukulungiswa kwe-microstructure akubonakali; ukwandisa umlinganiselo we-extrusion unokuphucula kakhulu iinkozo, ukuqhekeza isigaba sesibini esinqabileyo, ukufumana i-microstructure efanayo, kunye nokuphucula iimpawu zomatshini we-alloy.

I-6061 kunye ne-6063 ye-aluminium alloys iphinda ihlaziye amandla ngexesha lenkqubo yokukhupha. Xa ubushushu be-extrusion buhlala buhlala, njengoko umlinganiselo we-extrusion ukhula, ubukhulu bengqolowa buyancipha, isigaba sokuqinisa sihlakazwa kakuhle, kwaye ukuqina kwamandla kunye nokwandiswa kwe-alloy kwanda ngokufanelekileyo; nangona kunjalo, njengoko umlinganiselo we-extrusion ukhula, amandla okugqithisa afunekayo kwinkqubo yokukhupha nawo ayanda, abangela umphumo omkhulu we-thermal, obangela ukuba ukushisa kwangaphakathi kwe-alloy kunyuke, kunye nokusebenza kwemveliso kuyancipha. Olu vavanyo luphonononga isiphumo somlinganiselo we-extrusion, ngakumbi umlinganiselo omkhulu we-extrusion, kwi-microstructure kunye neempawu zomatshini ze-6063 i-aluminium alloy.

1 Imathiriyeli yovavanyo kunye neendlela

Izinto zovavanyo ziyi-6063 i-aluminium alloy, kwaye ukubunjwa kweekhemikhali kuboniswe kwiThebhile 1. Ubungakanani bokuqala be-ingot yi-Φ55 mm × 165 mm, kwaye icutshungulwa kwi-billet ye-extrusion kunye nobukhulu be-Φ50 mm × 150 mm emva kokunyangwa kwe-homogenization kwi-560 ℃ ye-6 h. Ibillet ifudunyezwa kwi-470 ℃ kwaye igcinwe ishushu. Ubushushu bokufudumala kombhobho we-extrusion yi-420 ℃, kunye nobushushu bokufudumala bomngundo yi-450 ℃. Xa isantya se-extrusion (i-extrusion intonga ehambayo) i-V = 5 mm / s ihlala ingatshintshi, amaqela ama-5 eemvavanyo ezahlukeneyo ze-extrusion ratios zenziwa, kunye ne-extrusion ratios R ziyi-17 (ehambelana nomngxuma wokufa D = 12 mm), 25 (D = 10 mm), 39 (D = 8 mm), 69 (D = 6 mm), 69 (D = 6 mm), 69 (D = 6 mm).

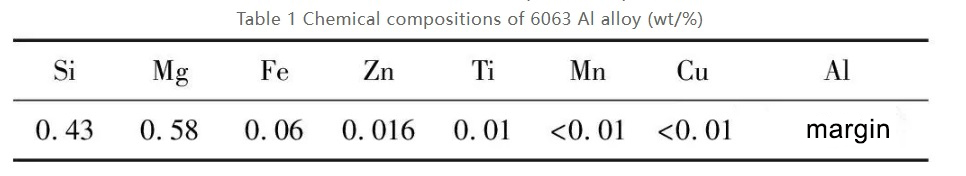

Itheyibhile 1 Ukwakhiwa kweekhemikhali ze-6063 Al alloy (wt/%)

Emva kokugaya i-sandpaper kunye nokupholisa ngomatshini, iisampuli ze-metallographic zifakwe kwi-reagent ye-HF kunye neqhekeza levolumu ye-40% malunga ne-25 s, kunye nesakhiwo se-metallographic yeesampuli zabonwa kwi-LEICA-5000 microscope ebonakalayo. Isampuli yokuhlalutya isicatshulwa kunye nobukhulu be-10 mm × 10 mm yasikwa ukusuka kumbindi wecandelo le-longitudinal yentonga ekhutshiweyo, kunye nokusila ngomatshini kunye ne-etching kwenziwa ukuze kususwe umgangatho woxinzelelo ongaphezulu. Izibalo zepali ezingaphelelanga zeeplanethi ezintathu zekristal {111}, {200}, kunye ne-{220} yesampulu zilinganiswe yi-X'Pert Pro MRD X-ray diffraction analyzer ye-PANalytical Company, kwaye idatha ye-texture iqhutywe kwaye ihlalutywe yi-X'Pert Data View kunye ne-software ye-X'Pert Texture.

I-tensile specimen ye-alloy cast ithathwe kumbindi we-ingot, kwaye i-tensile specimen yasikwa ecaleni kwendlela ye-extrusion emva kokukhutshwa. Ubungakanani bendawo yokulinganisa yayiyi-Φ4 mm×28 mm. Uvavanyo lwe-tensile lwenziwa kusetyenziswa i-SANS CMT5105 umatshini wokuvavanya imathiriyeli yendalo yonke enesantya se-2 mm/min. Umyinge wexabiso leesampuli ezintathu ezisemgangathweni zibalwe njengedatha yepropathi yomatshini. I-morphology yokwaphuka kwemizekelo yokuqina yabonwa kusetyenziswa imakroskopu ye-electron yokuskena yokukhulisa okuphantsi (Quanta 2000, FEI, USA).

2 Iziphumo kunye nengxoxo

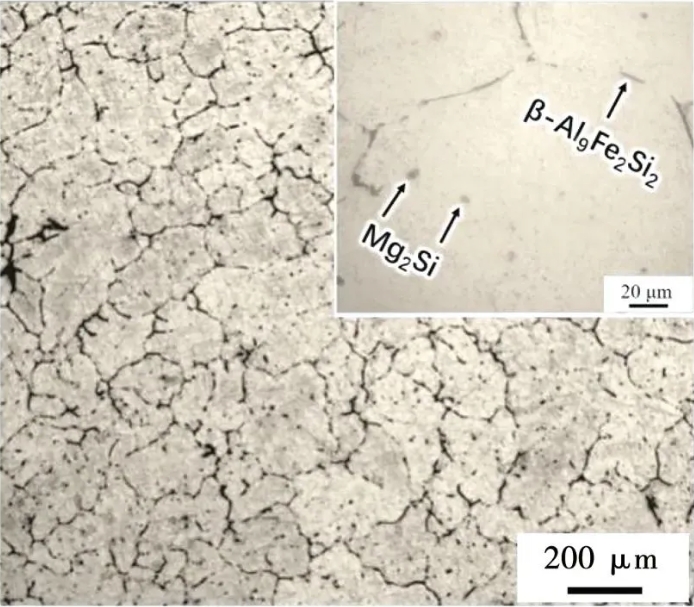

Umzobo we-1 ubonisa i-metallographic microstructure ye-as-cast 6063 aluminium alloy ngaphambi nangemva konyango lwe-homogenization. Njengoko kuboniswe kwi-Figure 1a, i-α-Al iinkozo kwi-microstructure ye-as-cast iyahluka ngobukhulu, inani elikhulu lezigaba ze-reticular β-Al9Fe2Si2 ziqokelela kwimida yengqolowa, kwaye inani elikhulu lezigaba ze-granular Mg2Si zikhona ngaphakathi kweenkozo. Emva kokuba i-ingot yenziwe i-homogenized kwi-560 ℃ kwi-6 h, i-non-equilibrium eutectic phase phakathi kwe-alloy dendrites yanyibilika ngokuthe ngcembe, i-alloy elements inyibilika kwi-matrix, i-microstructure yayifana, kunye ne-avareji yobukhulu beenkozo malunga ne-125 μm (Figure 1b).

Ngaphambi kwe-homogenization

Emva kwe-uniformizing unyango kwi-600 ° C kwiiyure ze-6

Umzobo.1 Isakhiwo se-Metallographic ye-6063 i-aluminium alloy ngaphambi nangemva konyango lwe-homogenization

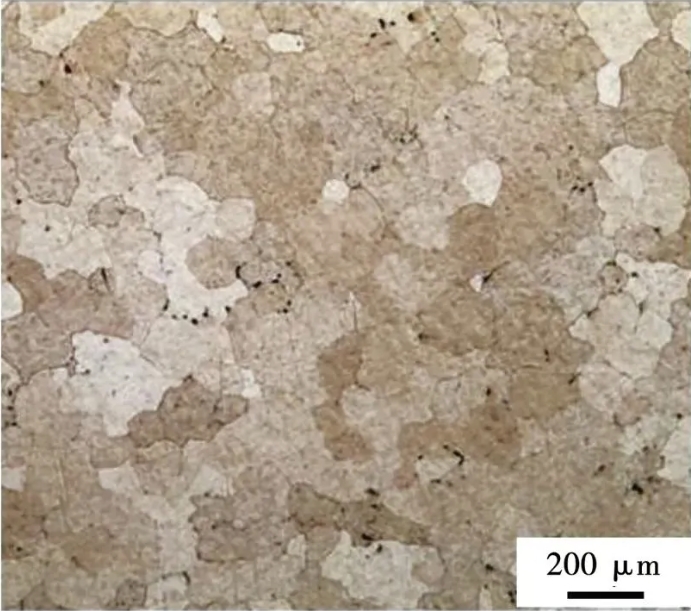

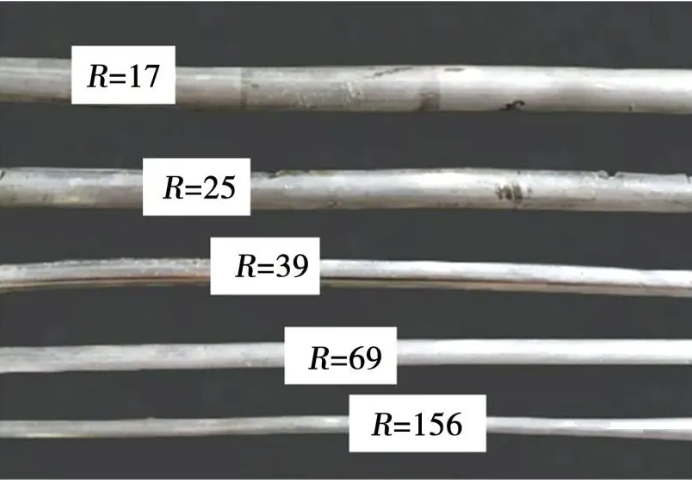

Umzobo we-2 ubonisa ukubonakala kwe-6063 imivalo ye-aluminium alloy kunye nemilinganiselo eyahlukeneyo ye-extrusion. Njengoko kubonisiwe kuMfanekiso 2, umgangatho womphezulu we-6063 imivalo ye-alluminiyam ekhutshiweyo kunye nemilinganiselo eyahlukeneyo ye-extrusion ilungile, ngakumbi xa umlinganiselo we-extrusion unyuswa ukuya kwi-156 (ngokuhambelana nesantya se-bar extrusion outlet ye-48 m / min), akukabikho ziphene ze-extrusion ezifana nokuqhekeka kunye nokuxobula, kumphezulu we-bar 60 aluminium i-barloid i-extrusion eshushu eyenza ukusebenza phantsi kwesantya esiphezulu kunye nomlinganiselo omkhulu we-extrusion.

Umfanekiso we-2 Ukubonakala kweentonga ze-6063 ze-aluminium alloy kunye ne-extrusion ratios ezahlukeneyo

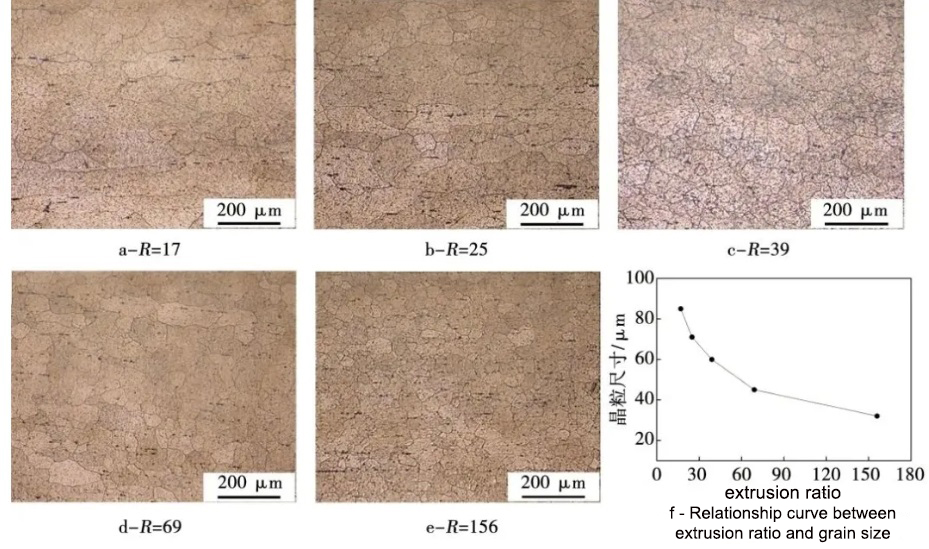

Umzobo we-3 ubonisa i-metallographic microstructure yecandelo le-longitudinal ye-6063 ye-aluminium alloy bar enemilinganiselo eyahlukeneyo ye-extrusion. Ulwakhiwo lweenkozo zebar enemilinganiselo eyahlukeneyo ye-extrusion ibonisa amanqanaba ahlukeneyo obude okanye ukucokisa. Xa umlinganiselo we-extrusion u-17, iinkozo zangaphambili zoluswa ecaleni kwendlela ye-extrusion, ehamba kunye nokubunjwa kwenani elincinci leenkozo ezihlaziyiweyo, kodwa iinkozo zisencinci, kunye nobukhulu obuziinkozo malunga ne-85 μm (Umfanekiso 3a); xa i-extrusion ratio i-25, iinkozo zitsalwa zincinci, inani leenkozo ezihlaziyiweyo landa, kwaye ubukhulu bengqolowa buyancipha ukuya malunga ne-71 μm (Umfanekiso 3b); xa i-extrusion ratio i-39, ngaphandle kwenani elincinci leenkozo ezikhubazekileyo, i-microstructure iqulunqwe ngokulinganayo iinkozo ezihlaziyiweyo zobukhulu obungalinganiyo, kunye nobukhulu obuziinkozo malunga ne-60 μm (Figure 3c); xa i-extrusion ratio i-69, inkqubo ye-recrystallization eguquguqukayo igqityiwe ngokusisiseko, i-grains ye-coarse yasekuqaleni iguqulwe ngokupheleleyo ibe yi-uniform structured recrystallized grains, kwaye ubungakanani bengqolowa obuqhelekileyo buhlanjululwe malunga ne-41 μm (Umfanekiso 3d); xa i-extrusion ratio i-156, kunye nenkqubela epheleleyo yenkqubo ye-recrystallization eguqukayo, i-microstructure ifana kakhulu, kwaye ubungakanani beenkozo buhlanjululwe kakhulu malunga ne-32 μm (Umfanekiso 3e). Ngokunyuka kwe-extrusion ratio, inkqubo ye-recrystallization eguquguqukayo iqhubeka ngakumbi, i-alloy microstructure iba yinto efanayo, kwaye ubukhulu bengqolowa bucocwe kakhulu (Umfanekiso 3f).

Umzobo 3 Ubume beMetallographic kunye nobungakanani beenkozo zecandelo elide le-6063 ye-aluminium alloy rods kunye ne-extrusion ratios eyahlukeneyo.

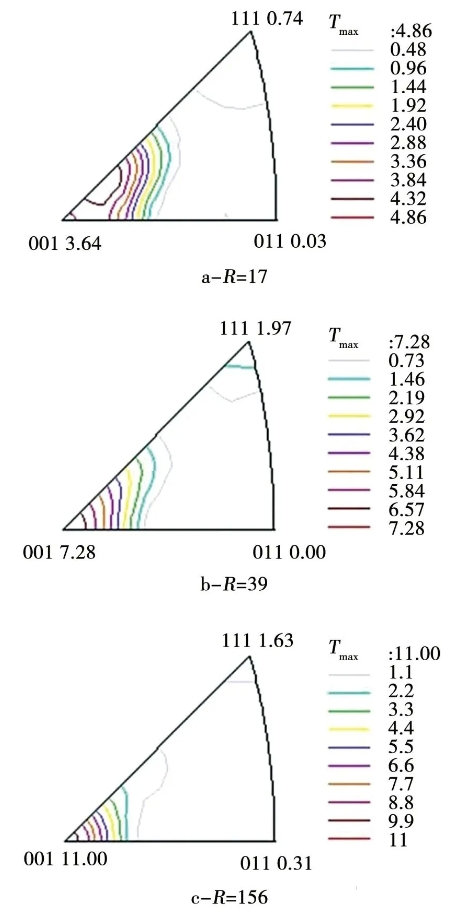

Umzobo we-4 ubonisa amanani epali e-inverse ye-6063 imivalo ye-aluminium alloy kunye nemilinganiselo eyahlukeneyo ye-extrusion ecaleni kwendlela ye-extrusion. Ingabonwa ukuba i-microstructures ye-alloy bar ene-extrusion ratios ezahlukeneyo zonke zivelisa ukuqhelaniswa okucacileyo okukhethiweyo. Xa umlinganiselo we-extrusion u-17, ubuthathaka <115>+<100> ukuthungwa kwenziwa (Umfanekiso 4a); xa umlinganiselo we-extrusion u-39, amacandelo e-texture anamandla ngakumbi <100> ukuthungwa kunye nomlinganiselo omncinci obuthathaka <115> ukuthungwa (Umfanekiso 4b); xa i-extrusion ratio yi-156, i-texture components yi-<100> ukuthungwa okunamandla okwandiswe kakhulu, ngelixa i-<115> i-texture iyanyamalala (Umfanekiso 4c). Uphononongo lubonise ukuba ubuso-centered cubic metals ikakhulu zenza <111> kunye <100> wire textures ngexesha extrusion kunye nomzobo. Nje ukuba i-texture yenziwe, iqondo lokushisa kwegumbi iimpawu zemishini ye-alloy zibonisa i-anisotropy ecacileyo. Amandla okuthungwa ayanda ngokunyuka kwe-extrusion ratio, ebonisa ukuba inani leenkozo kwindlela ethile ye-crystal ehambelana nolwalathiso lwe-extrusion kwi-alloy inyuka ngokuthe ngcembe, kwaye i-longitudinal tensile amandla e-alloy yanda. Iindlela zokuqiniswa kwe-6063 ye-aluminium alloy eshushu ye-extrusion materials iquka ukomeleza okuziinkozo, ukuqiniswa kwe-dislocation, ukuqiniswa kwe-texture, njl njl. Ngaphakathi koluhlu lweeparitha zenkqubo ezisetyenzisiweyo kolu vavanyo lovavanyo, ukwandisa umlinganiselo we-extrusion unempembelelo yokukhuthaza kwiindlela zokuqinisa ezi ngasentla.

Umzobo.4 Umzobo obuyiselwe umva wepali ye-6063 ye-aluminiyam i-alloy rods kunye ne-extrusion ratios eyahlukeneyo ecaleni kwendlela ye-extrusion.

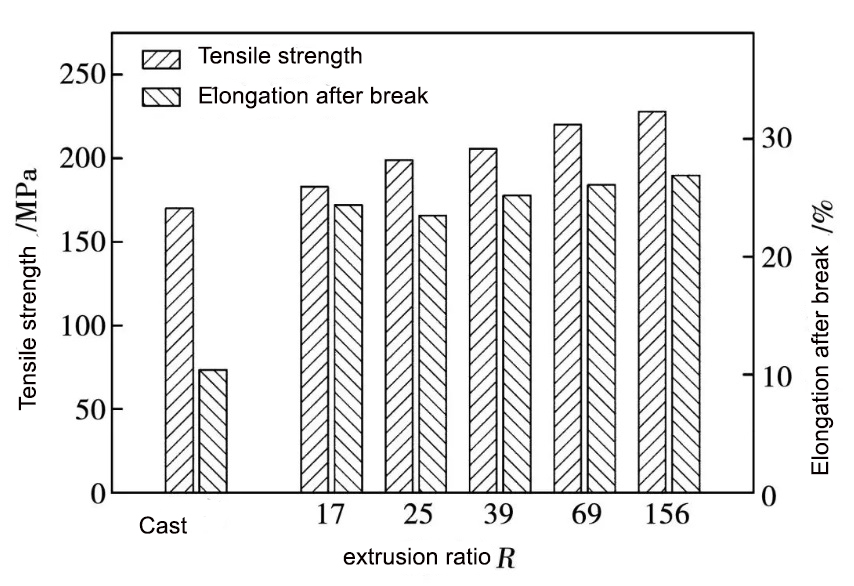

Umzobo we-5 yi-histogram yeempawu ze-tensile ze-6063 i-aluminium alloy emva kokuguqulwa kwemilinganiselo eyahlukeneyo ye-extrusion. Amandla e-tensile ye-alloy cast yi-170 MPa kwaye i-elongation yi-10.4%. Amandla okuqina kunye nobude be-alloy emva kwe-extrusion aphuculwe kakhulu, kwaye amandla okuqina kunye nobude onyuka ngokuthe ngcembe ngokunyuka komlinganiselo we-extrusion. Xa umlinganiselo we-extrusion u-156, amandla e-tensile kunye nokwandiswa kwe-alloy ukufikelela kwixabiso eliphezulu, elingama-228 MPa kunye ne-26.9%, ngokulandelanayo, malunga ne-34% ephezulu kune-tensile yamandla e-alloy kunye ne-158% ephezulu kunobude. Amandla e-tensile ye-6063 ye-aluminium alloy efunyenwe yi-extrusion ratio enkulu isondele kwixabiso lamandla e-tensile (240 MPa) efunyenwe yi-4-pass elinganayo i-channel e-angular extrusion (ECAP), ephezulu kakhulu kunexabiso lamandla e-tensile (171.1 MPa) efunyenwe yi-1-pass ECAP extrusion ye-6063 aluminium alloy. Ingabonwa ukuba umlinganiselo omkhulu we-extrusion unokuphucula iimpawu zomatshini we-alloy ukuya kwinqanaba elithile.

Ukwandiswa kweempawu zomatshini we-alloyi ngomlinganiselo we-extrusion uvela ikakhulu ekomelezeni ukuphuculwa kweenkozo. Njengoko umlinganiselo we-extrusion ukhula, iinkozo zihlanjululwa kwaye ukuxinana kwe-dislocation kuyanda. Imida eyongezelelweyo yeenkozo kwindawo nganye inokuthintela ngokufanelekileyo ukuhamba kwee-dislocation, kudibaniswa nokunyakaza okuhlangeneyo kunye nokudibanisa ukuchithwa, ngaloo ndlela kuphuculwe amandla e-alloy. I-grains egqwesileyo, i-tortuous ngakumbi imida yeenkozo, kunye ne-deformation yeplastiki inokuchithwa kwiinkozo ezininzi, ezingenakulungele ukubunjwa kweentanda, kungabikho ukusasazwa kweentanda. Amandla amaninzi anokuthatyathwa ngexesha lenkqubo yokuphuka, ngaloo ndlela kuphuculwe iplastiki ye-alloy.

Umzobo we-5 Iipropati ze-Tensile ze-6063 i-aluminium alloy emva kokuphosa kunye ne-extrusion

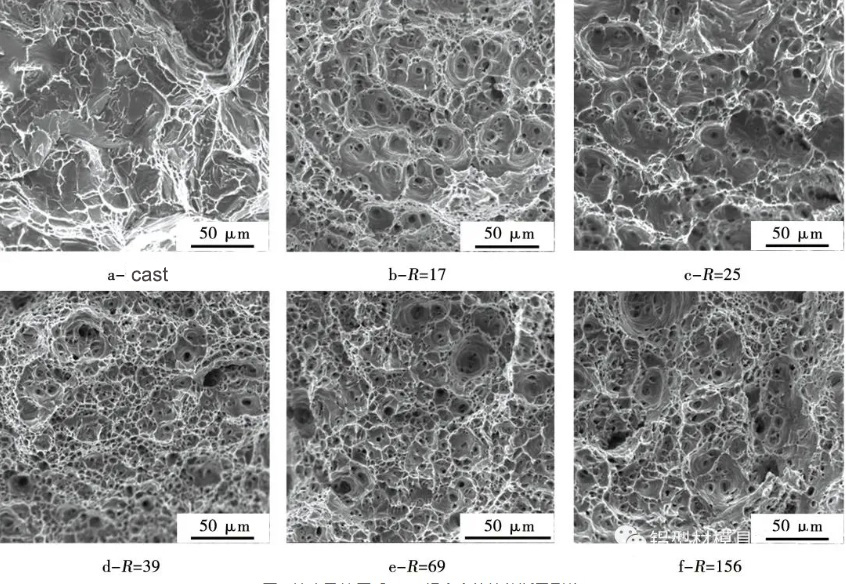

I-tenseration ye-tenphology morphology ye-Alloty emva kokupheliswa kwemilinganiselo eyahlukileyo ye-6. I-morphology ye-fracture ye-alloy emva kwe-extrusion ishintshile kakhulu, kwaye i-fracture iqulethwe inani elikhulu le-dimples equiaxed, ebonisa ukuba i-fracture mechanism ye-alloy emva kwe-extrusion ishintshile ukusuka kwi-brittle fracture ukuya kwi-ductile fracture. Xa umlinganiselo we-extrusion umncinci, i-dimples ayinzulu kwaye ubukhulu be-dimple bukhulu, kwaye ukusabalalisa akulingani; njengoko umlinganiselo we-extrusion ukhula, inani le-dimples liyanda, ubukhulu be-dimple buncinci kwaye ukusabalalisa kufanayo (Umfanekiso 6b ~ f), oku kuthetha ukuba i-alloy ine-plasticity engcono, ehambelana neziphumo zokuvavanya iimpawu ze-mechanical ngasentla.

3 Isiphelo

Kulo vavanyo, iimpembelelo zemilinganiselo eyahlukeneyo ye-extrusion kwi-microstructure kunye neepropati ze-6063 i-aluminium alloy zahlaziywa phantsi kwemeko yokuba ubungakanani be-billet, ukushisa kwe-ingot kunye nesantya se-extrusion sahlala singatshintshi. Izigqibo zezi zilandelayo:

I-1) I-recrystallization Dynamic iyenzeka kwi-6063 i-aluminium alloy ngexesha lokutshisa okutshisa. Ngokunyuka komlinganiselo we-extrusion, iinkozo zihlanjululwa ngokuqhubekayo, kwaye iinkozo ezikhutshiweyo kunye nolwalathiso lwe-extrusion ziguqulwa zibe yi-equiaxed recrystallized grains, kwaye amandla <100> ukuthungwa kwentambo kuyanda ngokuqhubekayo.

I-2) Ngenxa yempembelelo yokomeleza okuziinkozo, iimpawu zomatshini ze-alloy ziphuculwe ngokunyuka kwe-extrusion ratio. Ngaphakathi koluhlu lweeparamitha zokuvavanya, xa umlinganiselo we-extrusion uli-156, amandla okuqina kunye nokuphakama kwe-alloy afikelela kumaxabiso aphezulu angama-228 MPa kunye ne-26.9%, ngokulandelanayo.

Umzobo.6 I-Tensile fracture morphologies ye-6063 i-aluminium alloy emva kokuphosa kunye ne-extrusion

I-3) I-morphology ye-fracture ye-specimen ye-as-cast yenziwe ngeendawo ezithe tyaba kunye nemiphetho yokukrazula. Emva kwe-extrusion, i-fracture iqulethwe ngamanani amaninzi e-equiaxed dimples, kwaye indlela yokuphuka iguqulwa ukusuka kwi-brittle fracture ukuya kwi-ductile fracture.

Ixesha lokuposa: Nov-30-2024