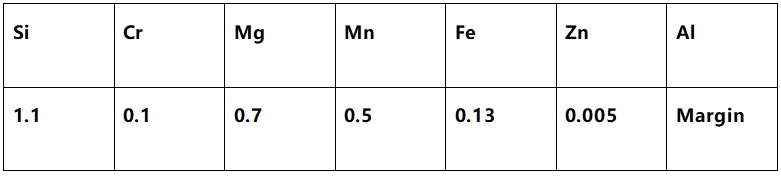

1. Ukuqulunqwa kwe-alloy

2. Inkqubo ye-Homogenization

390℃ x ukugqunywa kwe-1.0h + 575℃ x ukugquma kwe-8h, ukupholisa umoya onamandla ukuya kuma-200℃ kunye nokupholisa kwamanzi.

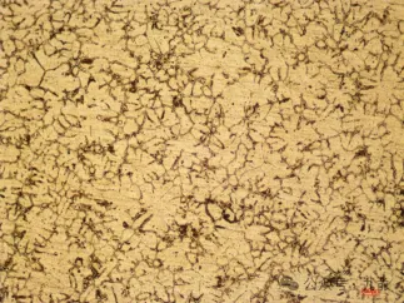

3. Ulwakhiwo lweMetallographic

Umzobo 1 Isakhiwo se-Metallographic ye-core ye-6082 ingot ye-alloy, efakwe yi-reagent ye-Keller, ene-dendrites ephuhliswe kakuhle.

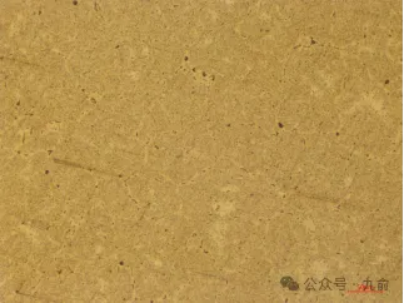

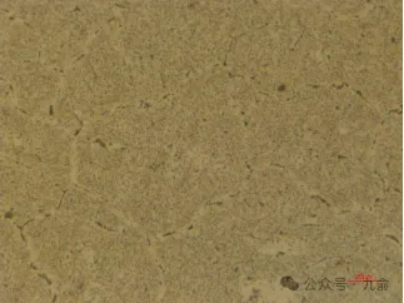

Umzobo 2 Isakhiwo se-Metallographic ye-core ye-6082 ingot ye-alloy, efakwe yi-reagent ye-Keller, kunye nesakhiwo emva kwesisombululo esiqinileyo.

4. Impembelelo ye-homogenization yonyango lokushisa kwisakhiwo se-alloy

4.1 Njengoko kuboniswe kwi-Figure 1, i-alloy ine-dendrites ephuhliswe kakuhle kwi-cast state, kwaye kukho inani elikhulu le-network non-equilibrium precipitation phases kwimida yengqolowa.

4.2 Ekubeni iindawo ezinyibilikayo zezinto ezahlukeneyo ziyahluka xa i-alloy iqina, le nto yokuqinisa ngokulandelelana ikhokelela ekubunjweni okungalinganiyo kwe-solute ngaphakathi kwekristale, ebonakaliswa ngokukodwa ekuveliseni inani elikhulu lezigaba zemvula yenethiwekhi kwimida yengqolowa.

4.3 Kwi-microstructure emva kokunyanga kwe-homogenization (Umfanekiso 2), inani lezigaba ezinqambileyo kwimida yengqolowa liyancipha kakhulu, kwaye ubukhulu bengqolowa buyanda ngokuhambelana. Oku kungenxa yokuba ukusasazwa kwee-athomu kuphuculwe phantsi kobushushu obuphezulu, ukupheliswa kocalucalulo kunye nokuchithwa kwesigaba esingalinganiyo kwenzeka kwi-ingot, kwaye iikhompawundi zenethiwekhi kwimida yeenkozo zichithwa ngokuyinxenye.

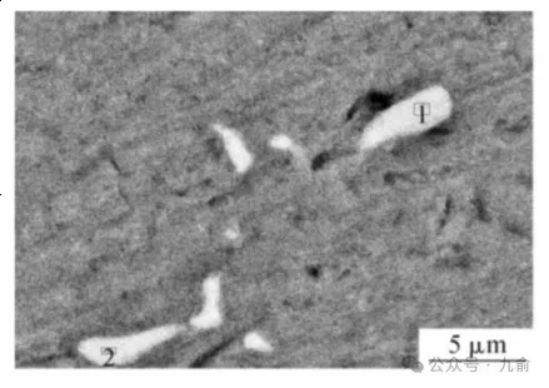

4.4 Ngokuhlalutya kwe-SEM, njengoko kubonisiwe kwi-FIG3, iindawo ezahlukeneyo zesigaba se-precipitated zakhethwa kuhlalutyo lwe-EDS, eqinisekisa ukuba i-precipitated phase yayiyi-Al(MnFe)Si phase.

4.5 Ngexesha lokwenziwa kwe-alloy casting, inani elikhulu le-Mn-containing precipitation phase lenziwe, kwaye inxalenye yalo igcinwe kwi-supersaturated solid solution. Emva kokushisa okuphezulu kunye nexesha elide lonyango lwe-homogenization, i-Mn i-supersaturated kwi-matrix iyancipha ngendlela ye-Mn-containing compounds, ebonakaliswa njengenani elikhulu le-Mn-containing particles decomposition particles precipitated in the crystal (Umfanekiso 2).

4.6 Ekubeni i-precipitated phase ine-Mn element, inozinzo oluhle lwe-thermal. Ngokuqiniswa kwe-atomic diffusion, i-Al (MnFe) Si isigaba samasuntswana ngokuthe ngcembe abonisa iimpawu ze-spheroidization.

Umfanekiso we-3 Al (MnFe)Si isigaba kwi-alloy ye-6082

5. Umphumo wenkqubo yokuguga isisombululo kwiipropati zomatshini

Emva kwe-homogenization, i-network precipitated phase ekuqaleni kumda weenkozo ze-6082 i-alloy iyachithwa, enokuphucula iimpawu zomatshini ezibanzi zesampuli. Ngaxeshanye, inqanaba elizinzileyo lokumelana nobushushu i-Al(MnFe)Si isigaba se-spheroidized ngakumbi, esinokuthi sibe ngcono ngokuqhawuka. Oku kubonisa ukuba ukusebenza okubanzi kwezinto kuya kuphuculwa emva kokunyanga kwe-homogenization yokushisa.

6. Isiphelo

6.1 I-6082 ingot ye-aluminium alloy ine-dendrites ephuhliswe kakuhle kunye nenani elikhulu le-network non-equilibrium precipitation phases kwimida yengqolowa.

I-6.2 Emva kokunyanga kwe-homogenization, ukubonwa kwe-microscopic kubonise ukuba inani lezigaba ezincitshisiweyo lancitshiswa kakhulu, kwaye ubukhulu bengqolowa banda ngokuhambelana. Ukupheliswa kokwahlulo kunye nokuchithwa kwesigaba esingalinganiyo kwenzeka kwi-ingot, kwaye i-network compounds kwimida yengqolowa yachithwa ngokuyinxenye.

6.3 Xa kusenziwa i-6082 alloy, i-Al(MnFe)Si isigaba semvula siyenziwa. Esi sigaba semvula siqulethe i-Mn element kwaye inozinzo oluhle lwe-thermal. Njengoko inkqubo ye-homogenization iqhubeka, iinqununu zesigaba semvula zibonisa ngokuthe ngcembe iimpawu ze-spheroidization. Le ngqungquthela ye-Mn-containing particles ihlakazwe ngokufanayo kwaye iyancipha kwi-crystal.

6.4 Emva konyango lwe-homogenization, ukuchithwa kwesigaba se-network precipitated sibonisa ukuba ukusebenza ngokubanzi kwe-ingot yonke kuphuculwe emva kokunyanga kokushisa kwe-homogenization.

Ixesha lokuposa: Jun-08-2025