Uvavanyo lokuqina lwamandla lusetyenziselwa ukumisela amandla ezinto zetsimbi ukuxhathisa umonakalo ngexesha lenkqubo yokwelula, kwaye yenye yezalathi ezibalulekileyo zokuvavanya iipropathi zoomatshini bezinto.

1. Uvavanyo lwe-tensile

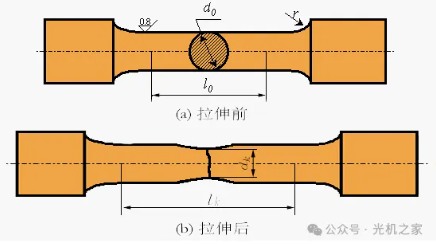

Uvavanyo lwe-tensile lusekwe kwimigaqo esisiseko ye-material mechanics. Ngokusebenzisa umthwalo we-tensile kwisampulu yezinto eziphathekayo phantsi kweemeko ezithile, kubangela i-tensile deformation de isampuli iphuke. Ngexesha lovavanyo, ukuguqulwa kwesampulu yovavanyo phantsi kwemithwalo eyahlukeneyo kunye nomthwalo ophezulu xa isampuli ikhefu irekhodwa, ukuze ubale amandla okuvelisa, amandla okuqina kunye nezinye izibonakaliso zokusebenza kwezinto.

Uxinzelelo σ = F/A

σ ngamandla okuqina (MPa)

F ngumthwalo we-tensile (N)

A yindawo enqamlezileyo yomfanekiso

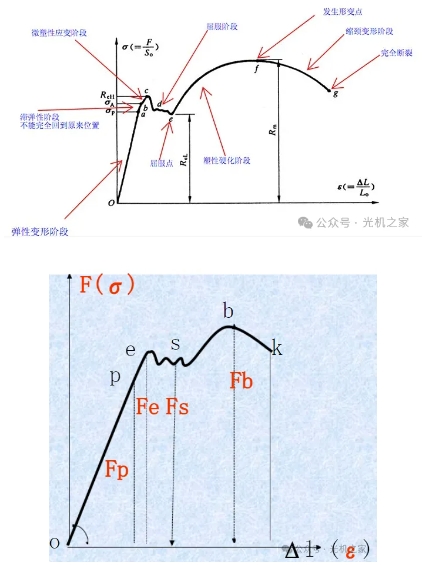

2. Igophe eliqinileyo

Uhlalutyo lwezigaba ezininzi zenkqubo yokwelula:

a. Kwinqanaba le-OP elinomthwalo omncinci, ukunyuswa kubudlelwane bomgca kunye nomthwalo, kwaye i-Fp ngumthwalo ophezulu wokugcina umgca ochanekileyo.

b. Emva kokuba umthwalo ugqithe kwi-Fp, ijika le-tensile liqala ukuthatha ubudlelwane obungenalo umgca. Isampuli ingena kwinqanaba lokuqala lokuguqulwa, kwaye umthwalo uyasuswa, kwaye isampuli inokubuyela kwimeko yayo yangaphambili kunye ne-elastically deform.

c. Emva kokuba umthwalo udlula i-Fe, umthwalo uyasuswa, inxalenye ye-deformation ibuyiselwe, kwaye inxalenye ye-deformation eseleyo igcinwe, ebizwa ngokuba yi-plastic deformation. I-Fe ibizwa ngokuba yi-elastic limit.

d. Xa umthwalo ukhula ngakumbi, ijika elijikayo libonisa i-sawtooth. Xa umthwalo unganyuki okanye unciphe, isenzeko sokwandiswa okuqhubekayo kwesampulu yovavanyo ibizwa ngokuba kukuvuma. Emva kokuvunwa, isampulu iqala ukwenza ukuguqulwa okucacileyo kweplastiki.

e. Emva kokuvuthwa, isampuli ibonisa ukunyuka kokuchasana kwe-deformation, ukuqina komsebenzi kunye nokuqiniswa kwe-deformation. Xa umthwalo ufikelela kwi-Fb, inxalenye efanayo yesampuli iyancipha ngokukhawuleza. Fb ngumda wamandla.

f. Isenzeko sokuncipha sikhokelela ekunciphiseni umthamo wokuthwala isampuli. Xa umthwalo ufikelela kwiFk, isampuli iyaphuka. Oku kubizwa ngokuba ngumthwalo wokwaphuka.

Unikeze Amandla

Amandla esivuno lilona xabiso loxinzelelo olukhulu olunokuthi luxhathise izinto zetsimbi ukusuka ekuqaleni kokuguqulwa kweplastiki ukugqiba ukuphuka xa uphantsi kwamandla angaphandle. Eli xabiso libonisa inqaku elibalulekileyo apho ukuguqulwa kwezinto eziphathekayo ukusuka kwinqanaba le-elastic deformation ukuya kwi-plastic deformation stage.

Ukuhlelwa

Amandla emveliso ephezulu: ibhekisa kuxinzelelo olukhulu lwesampulu ngaphambi kokuba amandla ehle okokuqala xa ukuvunwa kwenzeka.

Amandla esivuno esisezantsi: kubhekisa kuxinzelelo oluncinci kwinqanaba lesivuno xa isiphumo sokuqala esidlulayo singahoywa. Ekubeni ixabiso leqondo eliphantsi lesivuno lizinzile, lidla ngokusetyenziswa njengesalathisi sokumelana nezinto eziphathekayo, okubizwa ngokuba yi- yield point okanye amandla esivuno.

Ifomula yokubala

Ukufumana amandla aphezulu: i-R = F / Sₒ, apho i-F inamandla amakhulu phambi kokuba amandla ehla okokuqala kwinqanaba lokuvelisa, kwaye i-S- yindawo yokuqala ye-cross-sectional yesampuli.

Ukufumana amandla aphantsi okuvelisa: R = F / Sₒ, apho i-F inamandla amancinci F ngokungahoywa umphumo wokuqala wexeshana, kwaye i-S- yindawo yokuqala ye-cross-sectional yesampuli.

Iyunithi

Iyunithi yamandla esivuno idla ngokuba yiMPa (megapascal) okanye i-N/mm² (iNewton nge-square millimeter).

Umzekelo

Thatha i-carbon steel ephantsi njengomzekelo, umda wayo wesivuno udla ngokuba yi-207MPa. Xa iphantsi kwamandla angaphandle amakhulu kunomda, i-carbon steel ephantsi iya kuvelisa i-deformation esisigxina kwaye ayikwazi ukubuyiselwa; xa iphantsi kwamandla angaphandle angaphantsi kwalo mda, i-carbon steel ephantsi ingabuyela kwimeko yayo yangaphambili.

Amandla esivuno esinye sezibonakaliso ezibalulekileyo zokuvavanya iimpawu zemishini yezinto zetsimbi. Ibonisa amandla ezinto zokumelana nokuguqulwa kweplastiki xa iphantsi kwamandla angaphandle.

Tensile strength

Amandla e-tensile bubuchule besixhobo ukuxhathisa umonakalo phantsi komthwalo wokuzibamba, obonakaliswa ngokukodwa njengelona xabiso liphezulu loxinzelelo into enokumelana nayo ngexesha lenkqubo yokuqina. Xa uxinzelelo lwe-tensile kwizinto eziphathekayo ludlula amandla alo obunzima, izinto eziphathekayo ziya kuba ne-deformation yeplastiki okanye i-fracture.

Ifomula yokubala

Ifomyula yokubala yamandla e-tensile (σt) ithi:

σt = F / A

Apho u-F engowona mandla uphezulu we-tensile (i-Newton, N) enokumelana nomzekelo phambi kokuba waphulwe, kwaye u-A ngummandla woqobo onqamlezileyo womfanekiso (i-square millimeter, mm²).

Iyunithi

Iyunithi yamandla okuqina idla ngokuba yiMPa (megapascal) okanye i-N/mm² (iNewton nge-square millimeter). I-MPa eyi-1 ilingana ne-1,000,000 yeNewtons nge-square meter, ekwalingana no-1 N/mm².

Imiba enempembelelo

Amandla e-tensile achaphazeleka kwizinto ezininzi, kubandakanywa ukubunjwa kweekhemikhali, i-microstructure, inkqubo yonyango lokushisa, indlela yokucubungula, njl. Izinto ezahlukeneyo zinamandla ahlukeneyo, ngoko ke kwizicelo eziphathekayo, kuyimfuneko ukukhetha izinto ezifanelekileyo ezisekelwe kwiimpawu zomatshini wezinto eziphathekayo.

Ukusetyenziswa okusebenzayo

Amandla e-tensile yiparameter ebaluleke kakhulu kwinkalo yesayensi yezixhobo kunye nobunjineli, kwaye ihlala isetyenziselwa ukuvavanya iipropathi zoomatshini bezinto. Ngokumalunga noyilo lwesakhiwo, ukhetho lwezinto eziphathekayo, uvavanyo lokhuseleko, njl., amandla okuqina yinto ekufuneka iqwalaselwe. Ngokomzekelo, kubunjineli bokwakha, amandla okuqina ensimbi yinto ebalulekileyo ekunqumeni ukuba inokumelana nemithwalo; kwintsimi ye-aerospace, amandla okuqina obunzima kunye nezixhobo eziphezulu zamandla ngundoqo ekuqinisekiseni ukhuseleko lweenqwelo-moya.

Amandla okudinwa:

Ukukhathala kwesinyithi kubhekiselele kwinkqubo apho izinto kunye namacandelo avelisa ngokuthe ngcembe umonakalo oqokelelweyo wendawo kwindawo enye okanye kwiindawo ezininzi phantsi koxinzelelo lwe-cyclic okanye i-cyclic strain, kunye nokuqhekeka okanye ukuphuka okupheleleyo ngokukhawuleza emva kwenani elithile lemijikelo.

Iimbonakalo

Ngesiquphe ngexesha: Ukusilela kokudinwa kwesinyithi kuhlala kwenzeka ngequbuliso ngexesha elifutshane ngaphandle kweempawu ezicacileyo.

Indawo kwindawo: Ukungaphumeleli kokudinwa ngokuqhelekileyo kwenzeka kwiindawo zendawo apho uxinzelelo lugxininiswe.

Uvakalelo lokusingqongileyo kunye neziphene: Ukudinwa kwesinyithi kunovakalelo kakhulu kokusingqongileyo kunye neziphene ezincinci ngaphakathi kwemathiriyeli, ezinokukhawulezisa inkqubo yokudinwa.

Imiba enempembelelo

Uxinzelelo lwe-amplitude: Ubungakanani boxinzelelo buchaphazela ngokuthe ngqo ubomi bokukhathala kwesinyithi.

Umyinge woxinzelelo lobukhulu: Ubuninzi boxinzelelo oluphakathi, bufutshane ubomi bokudinwa kwesinyithi.

Inani lemijikelo: Amaxesha amaninzi isinyithi siphantsi koxinzelelo lwe-cyclic okanye uxinzelelo, ngakumbi ukuqokelela komonakalo wokukhathala.

Amanyathelo okuthintela

Lungiselela ukhetho lwemathiriyeli: Khetha izixhobo ezinemida ephezulu yokudinwa.

Ukunciphisa uxinzelelo loxinzelelo: Ukunciphisa uxinzelelo ngoyilo lwesakhiwo okanye iindlela zokucubungula, njengokusebenzisa iinguqu ezijikelezileyo zekona, ukwandisa imilinganiselo yecandelo, njl.

Ukunyangwa kwendawo: Ukupholisa, ukutshiza, njl njl kwi-metal surface ukunciphisa iziphene zomhlaba kunye nokuphucula amandla okukhathala.

Ukuhlola kunye nokugcinwa: Ukuhlola rhoqo amacandelo esinyithi ukuze ukhangele ngokukhawuleza kwaye ulungise iziphene ezifana neentanda; gcina amalungu athanda ukudinwa, njengokutshintsha iindawo ezigugileyo kunye nokuqinisa amakhonkco abuthathaka.

Ukukhathala kwesinyithi yindlela eqhelekileyo yokungaphumeleli kwesinyithi, ebonakaliswa ngokukhawuleza, indawo kunye novakalelo kwindalo. Uxinzelelo lwe-amplitude, ubukhulu boxinzelelo kunye nenani lemijikelezo zizinto eziphambili ezichaphazela ukukhathala kwesinyithi.

Ijika le-SN: lichaza ubomi bokukhathala bezinto eziphantsi kwamanqanaba ahlukeneyo oxinzelelo, apho i-S ibonisa uxinzelelo kwaye i-N ibonisa inani lemijikelezo yoxinzelelo.

Ifomula yomlinganiso wamandla okudinwa:

(Kf = Ka \cdot Kb \cdot Kc \cdot Kd \cdot Ke)

Apho (Ka) yinkalo yomthwalo, (Kb) yinkalo yobungakanani, (Kc) yinkalo yobushushu, (Kd) yinkalo yomgangatho womphezulu, kwaye (Ke) yinkalo yokuthembeka.

Inkcazo yezibalo yegophe ye-SN:

(\sigma^m N = C)

Apho (\ sigma) uxinzelelo, N linani lemijikelezo yoxinzelelo, kwaye m kunye no-C zizinto eziphathekayo.

Amanyathelo okubala

Qinisekisa izinto ezingaguqukiyo:

Qinisekisa ixabiso le-m kunye ne-C ngokusebenzisa iimvavanyo okanye ngokubhekisela kuncwadi olufanelekileyo.

Gqiba i-concentration factor factor: Qwalasela ubume bokwenyani kunye nobukhulu benxalenye, kunye nokugxininiswa koxinzelelo olubangelwa yi-fillets, keyways, njl., Ukugqiba i-concentration factor K. Bala amandla okukhathala: Ngokwe-SN curve kunye ne-stress concentration factor, idibaniswe nobomi bokuyila kunye nenqanaba loxinzelelo lomsebenzi wecandelo, bala amandla okukhathala.

2. Iplastiki:

I-Plastiki ibhekisela kwipropati yezinto ezinokuthi, xa ziphantsi kwamandla angaphandle, zivelise i-deformation engapheliyo ngaphandle kokuphulwa xa amandla angaphandle adlula umda we-elastic. Le deformation ayinakuguqulwa, kwaye izinto eziphathekayo aziyi kubuyela kwimo yayo yangaphambili nangona amandla angaphandle asusiwe.

Isalathiso sePlastiki kunye nefomula yayo yokubala

Ubude (δ)

Ingcaciso: Ukwandiswa yipesenteji yoguquko lulonke lwecandelo lokulinganisa emva kokuba i-specimen istensile yaphukile ukuya kubude begeyiji yokuqala.

Ifomula: δ = (L1 – L0) / L0 × 100%

Apho u-L0 bubude begeyiji yoqobo yomzekelo;

I-L1 bubude begeyiji emva kokuba isampuli yaphulwe.

Ukunciphisa ngokwamacandelo (Ψ)

Inkcazo: Ukuncitshiswa kwecandelo yipesenti yokunciphisa ubuninzi kwindawo enqamlezileyo kwindawo yentamo emva kokuba isampuli iphulwe kwindawo yokuqala.

Ifomula: Ψ = (F0 – F1) / F0 × 100%

Apho i-F0 yindawo yokuqala enqamlezileyo yomfanekiso;

I-F1 yindawo ye-cross-sectional point point emva kokuba i-specimen iphukile.

3. Ukuqina

Ubulukhuni bentsimbi yisalathisi sepropathi yomatshini ukulinganisa ubunzima bezinto zetsimbi. Ibonisa ukukwazi ukuxhathisa i-deformation kumthamo wendawo kwindawo yesinyithi.

Ukwahlula kunye nokumelwa kokuqina kwesinyithi

Ukuqina kwesinyithi kuneendlela ezahlukeneyo zokuhlela kunye neendlela zokubonisa ngokweendlela ezahlukeneyo zovavanyo. Iquka oku kulandelayo:

Ukuqina kweBrinell (HB):

Ububanzi besicelo: Isetyenziswa ngokubanzi xa imathiriyeli ithambile, njengesinyithi esingeyontsimbi, intsimbi phambi kokunyangwa kobushushu okanye emva kokufakwa.

Umgaqo wokuvavanya: Ngobungakanani obuthile bomthwalo wokuvavanya, ibhola yensimbi eqinile okanye ibhola ye-carbide yobubanzi obuthile icinezelwe kwindawo yesinyithi ukuze ihlolwe, kwaye umthwalo ukhululiwe emva kwexesha elithile, kunye nobubanzi be-indentation phezu komgangatho oza kuvavanywa.

Ifomula yokubala: Ixabiso lobulukhuni beBrinell yi-quotient efunyenwe ngokwahlula-hlula umthwalo ngendawo engqukuva yomphezulu we-indent.

Ukuqina kweRockwell (HR):

Ububanzi besicelo: Ngokuqhelekileyo isetyenziselwa izinto ezinobunzima obuphezulu, obufana nobulukhuni emva konyango lobushushu.

Umgaqo wovavanyo: Iyafana nobulukhuni beBrinell, kodwa kusetyenziswa iiprobe ezahlukeneyo (diamond) kunye neendlela ezahlukeneyo zokubala.

Iindidi: Ngokuxhomekeke kwisicelo, kukho i-HRC (yezinto zobunzima obuphezulu), i-HRA, i-HRB kunye nezinye iintlobo.

Ubunzima bukaVickers (HV):

Ububanzi besicelo: Ifanelekile uhlalutyo lwe-microscope.

Umgaqo wovavanyo: Cinezela umphezulu wezinto eziphathekayo kunye nomthwalo ongaphantsi kwe-120kg kunye ne-diamond square cone indenter kunye ne-engile ye-vertex ye-136 °, kwaye uhlukanise indawo yomphezulu we-indentation emhadini ngexabiso lomthwalo ukufumana ixabiso lobulukhuni beVickers.

Ubunzima beLeeb (HL):

Iimpawu: Umvavanyi wobulukhuni obuphathekayo, kulula ukulinganisa.

Umgaqo wokuvavanya: Sebenzisa i-bounce eyenziwe yintloko yebhola yempembelelo emva kokuchaphazela ubulukhuni bomhlaba, kwaye ubale ubulukhuni ngomlinganiselo wesantya se-punch kwi-1mm ukusuka kwisampuli yomhlaba ukuya kwisantya sempembelelo.

Ixesha lokuposa: Sep-25-2024