Nangona phantse zonke ii-alloys ze-aluminium zigqithisekile kwithiyori, ukuvavanya ukugqithiswa kwenxalenye ethile kufuna ukuqwalaselwa ngokubanzi kwezinto ezifana nemilinganiselo, ijometri, uhlobo lwe-alloy, iimfuno zokunyamezela, isantya se-scrap, i-extrusion ratio, kunye nomlinganiselo wolwimi. Ukongezelela, kubalulekile ukugqiba ukuba i-extrusion ngokuthe ngqo okanye engathanga ngqo yindlela efanelekileyo yokwenza.

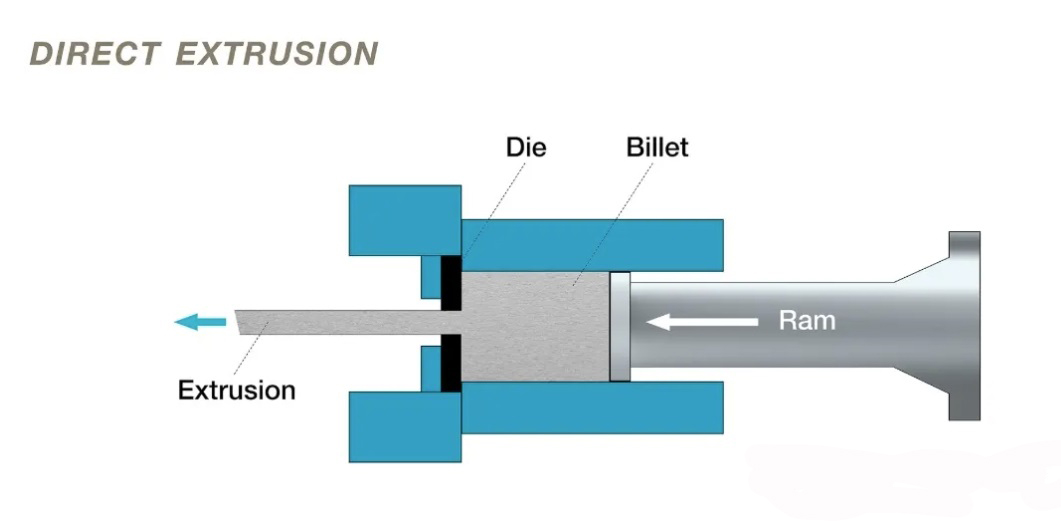

I-extrusion ethe ngqo yinkqubo esetyenziswa ngokuqhelekileyo, ebonakaliswe ngokuyila kwayo elula kunye nokulungelelanisa okunamandla, okwenza ukuba ifaneleke kuluhlu olubanzi lwemveliso yeprofayili. Ngale ndlela, i-billet ye-aluminium eshushu ngaphambili ityhalwa ngenkunzi yegusha ngokufa okumileyo, kwaye izinto zihamba ngendlela efanayo nenkunzi yegusha. Ukukhuhlana phakathi kwebillet kunye nesikhongozeli kuhambelana nale nkqubo. Le ngxabano ibangela ukufudumala kobushushu kunye nokunyuka kokusetyenziswa kwamandla, okukhokelela ekuhlukeni kweqondo lokushisa kunye nomsebenzi wokuguqula ubude be-extrusion. Ngenxa yoko, ezi zintlukwano zinokuchaphazela ukwakheka kweenkozo, i-microstructure, kunye nokuzinza kwe-dimensional yemveliso yokugqibela. Ngaphezu koko, ekubeni uxinzelelo luthande ukuhla kuwo wonke umjikelo we-extrusion, imilinganiselo yeprofayili inokungahambelani.

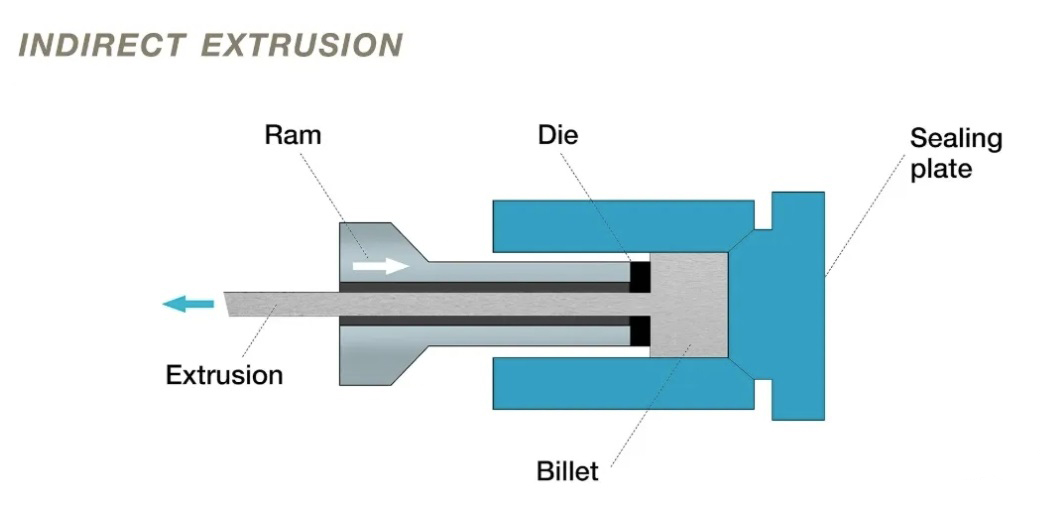

Ngokwahlukileyo, i-extrusion engathanga ngqo ibandakanya ukufa okubekwe kwinkunzi yegusha ekhuphayo efaka uxinzelelo kwicala elichaseneyo nebillet ye-aluminium emileyo, ebangela ukuba izinto ziphume zibuyele umva. Ngenxa yokuba i-billet ihlala i-static xa ihambelana nesitya, akukho friction ye-billet-to-container. Oku kubangela amandla okwenza okuhambelanayo kunye negalelo lamandla kuyo yonke inkqubo. I-deformation efanayo kunye neemeko zokushisa eziphunyeziweyo ngeemveliso zemveliso ye-extrusion engathanga ngqo ngokuchaneka okuphuculweyo kwe-dimensional, i-microstructure engaguqukiyo, kunye neempawu zomatshini eziphuculweyo. Le ndlela inenzuzo ngokukhethekileyo kwizicelo ezifuna ukuhambelana okuphezulu kunye nokuguquguquka, okufana nesitokhwe somatshini we-screw.

Nangona izibonelelo zayo ze-metallurgical, i-extrusion engathanga ngqo inemida ethile. Nakuphi na ukungcoliseka kwendawo kwi-billet kunokuchaphazela ngokuthe ngqo ukugqitywa komphezulu we-extrudate, okwenza kube yimfuneko ukususa i-as-cast surface kunye nokugcina i-billet surface ecocekileyo. Ukongezelela, ngenxa yokuba ukufa kufuneka kuxhaswe kwaye kuvumele ukuba i-extrudate idlule, ubukhulu beprofayili obuvumelekileyo buncitshisiwe, ukunciphisa ubungakanani beemilo ezigqithisiweyo.

Ngenxa yeemeko zayo ezizinzileyo zenkqubo, ukwakheka okufanayo, kunye nokuhambelana komgangatho ophezulu, i-extrusion engathanga ngqo ibe yindlela ebalulekileyo yokuvelisa iintonga ze-aluminium eziphezulu kunye nemivalo. Ngokunciphisa ukuhluka kwenkqubo ngexesha le-extrusion, iphakamisa kakhulu ubugcisa kunye nokuthembeka kwesicelo seemveliso ezigqityiweyo.

Ixesha lokuposa: Jul-16-2025