Ukuba iipropathi zomatshini ze-extrusions azikho njengoko zilindelwe, ingqwalasela idla ngokujoliswa ekubunjweni kokuqala kwe-billet okanye iimeko ze-extrusion / zokuguga. Bambalwa abantu ababuza ukuba i-homogenization ngokwayo ingaba ngumcimbi. Ngapha koko, inqanaba le-homogenization libalulekile ekuveliseni ii-extrusions ezikumgangatho ophezulu. Ukungaphumeleli ukulawula ngokufanelekileyo inyathelo le-homogenization kunokukhokelela ku:

●Uxinzelelo olwandayo

●Iziphene ezingakumbi

●Imizobo ye-Streak emva kwe-anodizing

●Isantya esisezantsi se-extrusion

● Iimpawu zoomatshini ezingalunganga

Isigaba se-homogenization sineenjongo ezimbini eziphambili: ukucoca i-iron-containing intermetallic compounds, kunye nokusabalalisa i-magnesium (Mg) kunye ne-silicon (Si). Ngokuphonononga i-microstructure ye-billet ngaphambi nangemva kwe-homogenization, umntu unokuqikelela ukuba i-billet iya kwenza kakuhle ngexesha le-extrusion.

Isiphumo se-Billet Homogenization kwi-Hardening

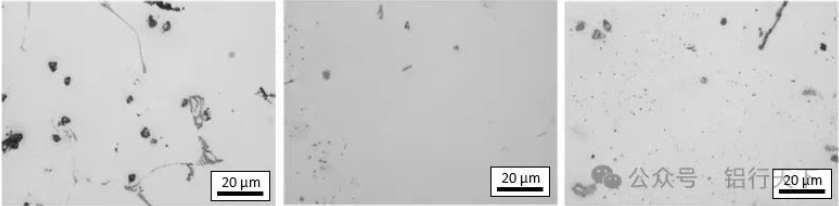

Kwi-extrusions ye-6XXX, amandla avela kwizigaba ze-Mg- kunye ne-Si-rich ezenziwe ngexesha lokuguga. Ukukwazi ukwenza ezi zigaba kuxhomekeke ekubekeni izinto kwisisombululo esiqinileyo ngaphambi kokuba ukuguga kuqale. Ukuze i-Mg kunye ne-Si ekugqibeleni ibe yinxalenye yesisombululo esiqinileyo, isinyithi kufuneka sicinywe ngokukhawuleza ukusuka ngaphezu kwe-530 °C. Kumaqondo obushushu angaphezu kweli nqanaba, iMg kunye neSi zinyibilika ngokwendalo zibe yialuminiyam. Nangona kunjalo, ngexesha le-extrusion, isinyithi sihlala kuphela ngaphezu kweqondo lokushisa ixesha elifutshane. Ukuqinisekisa ukuba zonke i-Mg kunye ne-Si ziyanyibilika, i-Mg kunye ne-Si particles kufuneka ibe yincinci. Ngelishwa, ngexesha lokuphosa, i-Mg kunye ne-Si iyancipha njengeebhloko ezinkulu ze-Mg₂Si (Umfanekiso 1a).

Umjikelo oqhelekileyo we-homogenization ye-6060 billets yi-560 °C kwiiyure ze-2. Ngethuba le nkqubo, ekubeni i-billet ihlala ngaphezu kwe-530 ° C ixesha elide, i-Mg₂Si iyachithwa. Emva kokupholisa, iphinda iphinde iphinde isasazeke kakuhle kakhulu (Umfanekiso 1c). Ukuba iqondo lokushisa le-homogenization aliphezulu ngokwaneleyo, okanye ixesha lifutshane kakhulu, ezinye iinqununu ezinkulu zeMg₂Si ziya kuhlala. Xa oku kwenzeka, isisombululo esiluqilima emva kwe-extrusion siqulethe i-Mg encinci kunye ne-Si, okwenza kube nzima ukwenza uxinaniso oluphezulu lwe-precipitates elukhuni-ekhokelela ekunciphiseni iimpawu zomatshini.

Umzobo 1. Iimicrographs zamehlo ezipolishiwe kunye ne-2% ye-HF-etched 6060 billets: (a) as-cast, (b) i-homogenized ngokuyinxenye, (c) i-homogenized ngokupheleleyo.

Indima ye-Homogenization kwi-Iron-containing Intermetallics

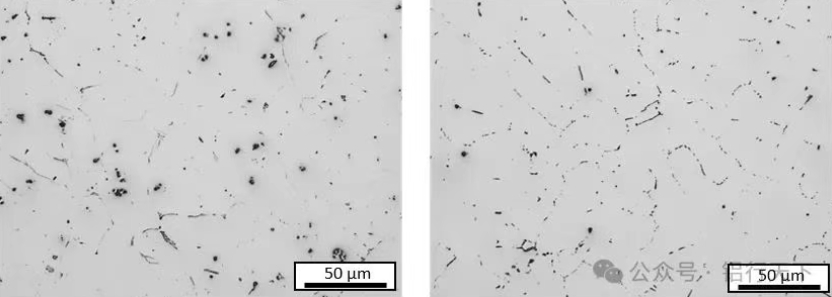

I-Iron (Fe) inefuthe elikhulu kukuqina kokwaphuka kunamandla. Kwi-alloys ye-6XXX, izigaba ze-Fe zivame ukwenza i-β-phase (Al₅(FeMn)Si okanye i-Al₈.₉(FeMn)₂Si₂) ngexesha lokuphosa. Ezi zigaba zikhulu, i-angular, kwaye ziphazamisa i-extrusion (echazwe kwi-Fig. 2a). Ngexesha le-homogenization, izinto ezinzima (Fe, Mn, njl.) zisasazeka, kwaye izigaba ezinkulu ze-angular ziba zincinci kwaye zijikeleze (Umfanekiso 2b).

Ukususela kwimifanekiso ye-optical yodwa, kunzima ukuhlukanisa izigaba ezahlukeneyo, kwaye akunakwenzeka ukulinganisa ngokuthembekileyo. Kwi-Innoval, silinganisela i-billet homogenization sisebenzisa indlela yethu yangaphakathi yokufumanisa kunye nokuhlelwa (FDC), ebonelela ngexabiso le-% α yeebhilithi. Oku kusenza sikwazi ukuvavanya umgangatho we-homogenization.

Umzobo 2. Iimicrographs ze-Optical of billets (a) ngaphambi kunye (b) emva kwe-homogenization.

Indlela yokufunyanwa kunye noHlelo (FDC).

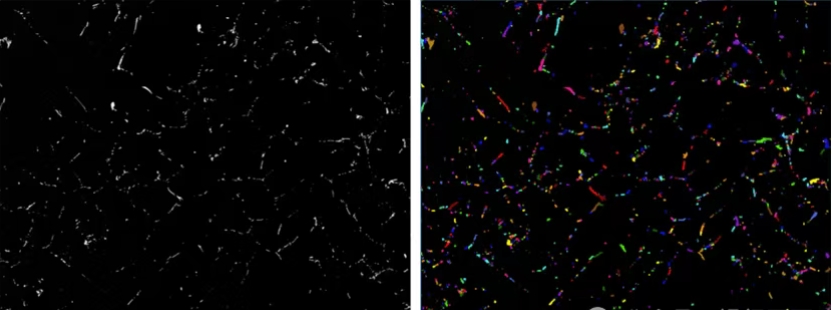

Umfanekiso we-3a ubonisa isampuli epholisiweyo ehlalutywe ngokuskena i-electron microscopy (SEM). Ubuchule bokuvula i-grayscale thresholding buthi busetyenziswe ukwahlula kunye nokuchonga ii-intermetallics, ezibonakala zimhlophe kuMzobo 3b. Obu buchule buvumela uhlalutyo lweendawo ukuya kuthi ga kwi-1 mm², okuthetha ukuba ngaphezu kwe-1000 iimpawu zomntu ngamnye zinokucazululwa kanye.

Umzobo 3. (a) Umfanekiso we-electron osasaziweyo we-homogenized 6060 billet, (b) ichongiwe iimpawu zomntu ngamnye ku-(a).

Ukuqulunqwa kweNcam

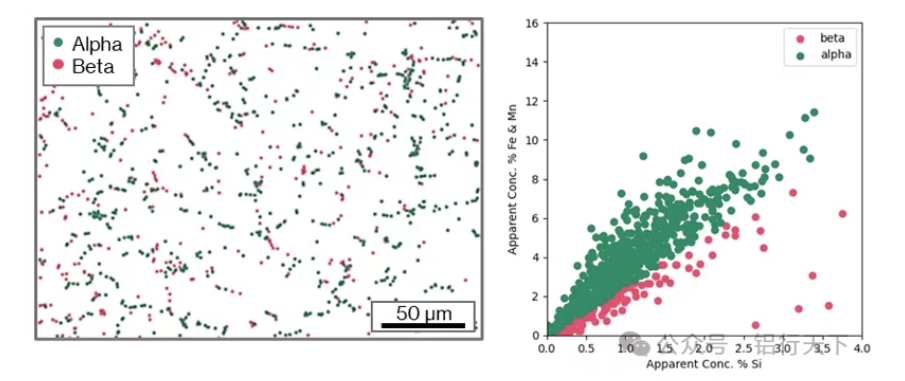

Inkqubo ye-Innoval ixhotyiswe nge-Oxford Instruments Xplore 30 i-energy-dispersive X-ray (EDX) detector. Oku kuvumela ukuqokelelwa ngokukhawuleza okuzenzekelayo kwe-EDX spectra ukusuka kwindawo nganye echongiweyo. Ukusuka kwezi spectra, ukwakheka kwamasuntswana kunokumiselwa, kwaye isihlobo Fe: Si ratio inferred.

Ngokuxhomekeke kumxholo we-Mn okanye we-Cr we-alloy, ezinye izinto ezinzima zingabandakanywa. Kwezinye ii-alloys ezingama-6XXX (ngamanye amaxesha nge-Mn ebalulekileyo), umlinganiselo (Fe+Mn):Si usetyenziswa njengesalathiso. Olu lungelelwaniso lunokuthi ke luthelekiswe nezo zaziwa ngokuba zii-Fe-containing intermetallics.

β-phase (Al₅(FeMn)Si okanye Al₈.₉(FeMn)₂Si₂): (Fe+Mn):Si ratio ≈ 2. α-phase (Al₁₂(FeMn)₃Si okanye iAl₈.₃(FeMn)₂,i-si) kuxhomekeke kwi. Isoftware yethu yesiko ivumela ukuba sibeke umda kwaye sihlele i-particle nganye njenge-α okanye i-β, emva koko imephu yeendawo zabo ngaphakathi kwe-microstructure (umzobo 4). Oku kunika ipesenti eqikelelweyo yokuguqulwa kwe-α kwi-homogenized billet.

Umzobo 4. (a) Imephu ebonisa amasuntswana e-α- kunye no-β-classified, (b) iploti yokuchithachitha ka (Fe+Mn):Imilinganiselo yeSi.

Yintoni enokusixelelwa yiDatha

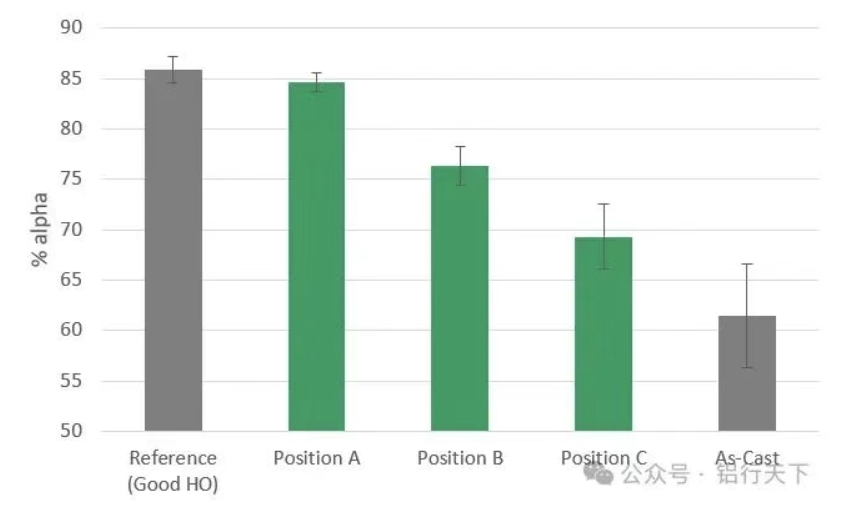

Umfanekiso wesi-5 ubonisa umzekelo wendlela olu lwazi lusetyenziswa ngayo. Kule meko, iziphumo zibonisa ukufudumeza okungafaniyo ngaphakathi kwesithando somlilo esithile, okanye mhlawumbi ukuba ukushisa kwe-setpoint akuzange kufikelelwe. Ukuvavanya ngokufanelekileyo iimeko ezinjalo, zombini i-billet yovavanyo kunye neereferensi zeebhilidi zomgangatho owaziwayo ziyafuneka. Ngaphandle kwezi, uluhlu olulindelekileyo lwe-% α lolo kwakheka kwe-alloyi alunakusekwa.

Umzobo 5. Ukuthelekiswa kwe-% α kumacandelo ahlukeneyo esithandweni somlilo se-homogenization esingasebenzi kakuhle.

Ixesha lokuposa: Aug-30-2025