Ubukhulu bodonga olukhulu lwe-6061T6 i-aluminium alloy kufuneka lucinywe emva kokutshisa okutshisayo. Ngenxa yokunciphisa i-extrusion engapheliyo, inxalenye yeprofayili iya kungena kwindawo yokupholisa amanzi ngokulibaziseka. Xa i-ingot emfutshane elandelayo iqhubeleka nokukhutshelwa, le nxalenye yeprofayile iya kucinywa ngokulibaziseka. Indlela yokujongana nommandla wokucima ulibaziseko ngumba ekufuneka iwuqwalasele yonke inkampani yemveliso. Xa inkunkuma yenkqubo yomsila we-extrusion imfutshane, iisampuli zokusebenza ezithathiweyo ngamanye amaxesha zifanelekile kwaye ngamanye amaxesha azifaneleki. Xa uphinda usampula ukusuka kwicala, ukusebenza kuyafaneleka kwakhona. Eli nqaku linika ingcaciso ehambelanayo ngokusebenzisa imifuniselo.

1. Izinto zokuvavanya kunye neendlela

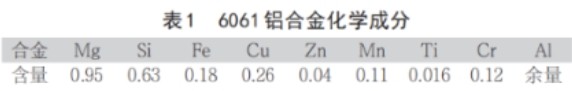

Izinto ezisetyenzisiweyo kolu vavanyo yi-6061 aluminium alloy. Ukubunjwa kwayo kweekhemikhali kulinganiswa ngohlalutyo lwe-spectral ngolu hlobo lulandelayo: Ihambelana ne-GB / T 3190-1996 ngamazwe ngamazwe 6061 i-aluminium alloy composition standard.

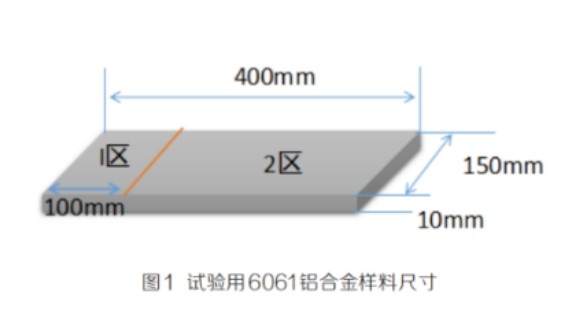

Kolu vavanyo, inxalenye yeprofayili eyongeziweyo yathathwa kunyango lwesisombululo esiluqilima. Iprofayile ye-400mm ubude yohlulwe kwiindawo ezimbini. Ummandla we-1 wawupholiswe ngokuthe ngqo ngamanzi kwaye ucinywe. Indawo yesi-2 yapholiswa emoyeni imizuzwana engama-90 emva koko yapholiswa ngamanzi. Umzobo wovavanyo uboniswe kuMfanekiso 1.

Iprofayili ye-6061 ye-aluminium alloy esetyenzisiweyo kolu vavanyo yakhutshwa yi-4000UST extruder. Ukushisa kwe-mold yi-500 ° C, ukushisa kwentonga yokuphosa yi-510 ° C, i-extrusion outlet ye-extrusion yi-525 ° C, i-extrusion speed yi-2.1mm / s, ukupholisa kwamanzi aphezulu kusetyenziswa ngexesha lenkqubo yokukhupha, kunye nobude be-400mm yokuvavanya isicatshulwa sithathwa phakathi kweprofayili egqityiweyo. Ububanzi besampulu yi-150mm kwaye ukuphakama yi-10.00mm.

Iisampulu ezithathiweyo zahlulahlulwe kwaye emva koko ziphantsi konyango lwesisombululo kwakhona. Iqondo lokushisa lesisombululo laliyi-530 ° C kwaye ixesha lesisombululo laliyi-4 iiyure. Emva kokuwakhupha, iisampulu zafakwa kwitanki enkulu yamanzi enobunzulu bamanzi obuyi-100mm. Itanki enkulu yamanzi inokuqinisekisa ukuba ubushushu bamanzi kwitanki yamanzi butshintsha kancinci emva kokuba isampuli kwindawo ye-1 ipholile ngamanzi, ukuthintela ukunyuka kwamaqondo okushisa kwamanzi ukuba kuthintele ukupholisa kwamanzi. Ngexesha lokupholisa amanzi, qinisekisa ukuba ubushushu bamanzi buphakathi kwe-20-25 ° C. Iisampuli ezicinyiweyo zazikhulile kwi-165 ° C * 8h.

Thatha inxalenye yesampuli 400mm ubude 30mm ububanzi 10mm ubukhulu, kwaye wenze uvavanyo Brinell ubulukhuni. Yenza imilinganiselo emi-5 rhoqo nge-10mm. Thatha i-avareji yexabiso le-5 ye-Brinell hardnesses njengoko isiphumo sobunzima be-Brinell kweli nqanaba, kwaye ujonge ipateni yokutshintsha ubulukhuni.

Iimpawu zomatshini zeprofayili zavavanywa, kwaye icandelo elihambelana ne-tensile i-60mm lilawulwa kwiindawo ezahlukeneyo zesampuli ye-400mm ukujonga iipropati ezithintekayo kunye nendawo yokuphuka.

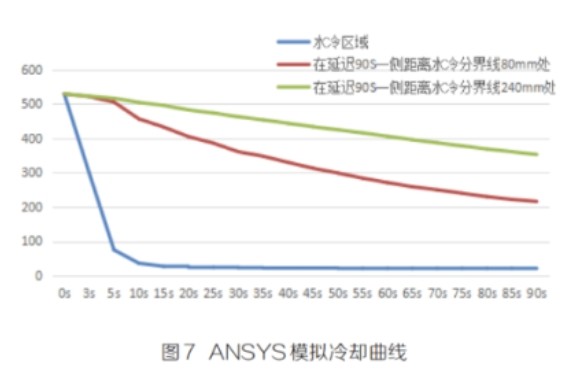

Intsimi yokushisa yokucima kwamanzi okupholisa isampuli kunye nokucima emva kokulibaziseka kwe-90s ifaniswe ngesofthiwe ye-ANSYS, kunye namazinga okupholisa amaphrofayili kwiindawo ezahlukeneyo ahlalutywa.

2. Iziphumo zovavanyo kunye nohlalutyo

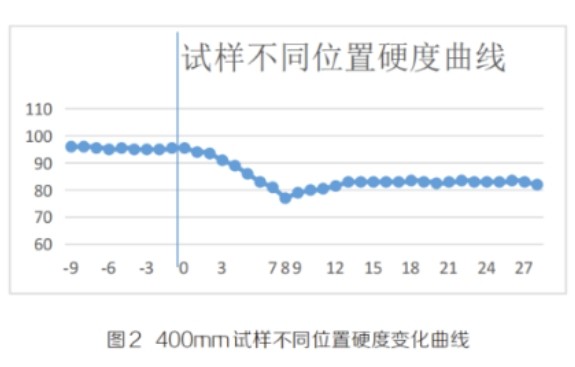

2.1 Iziphumo zovavanyo lokuqina

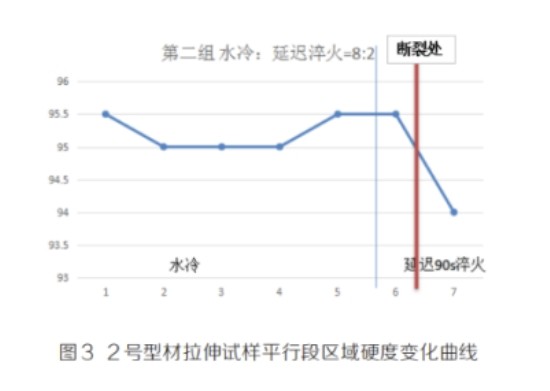

Umzobo we-2 ubonisa ijika lokutshintsha ubulukhuni besampuli ye-400mm ubude obulinganiswe ngumhloli wobulukhuni be-Brinell (ubude beyunithi ye-abscissa imele i-10mm, kwaye umlinganiselo we-0 ngumgca wokuhlula phakathi kokucima okuqhelekileyo kunye nokulibaziseka kokucima). Kunokufunyanwa ukuba ukuqina kwisiphelo sokupholisa amanzi kuzinzile malunga ne-95HB. Emva komgca wokuhlula phakathi kokucima ukupholisa kwamanzi kunye nokulibaziseka kwe-90s yokupholisa amanzi, ubunzima buqala ukuhla, kodwa izinga lokuhla licotha kwinqanaba lokuqala. Emva kwe-40mm (89HB), ukuqina kwehla ngokukhawuleza, kwaye kwehla kwixabiso eliphantsi (77HB) kwi-80mm. Emva kwe-80mm, ubunzima abuzange buqhubeke buyancipha, kodwa bunyuke ukuya kwinqanaba elithile. Ulwando lwaluluncinane ngokwentelekiso. Emva kwe-130mm, ukuqina kwahlala kungatshintshanga malunga ne-83HB. Kungacingelwa ukuba ngenxa yesiphumo sokuqhuba ubushushu, izinga lokupholisa lenxalenye yokulibaziseka yokucima itshintshile.

2.2 Iziphumo zovavanyo lwentsebenzo kunye nocazululo

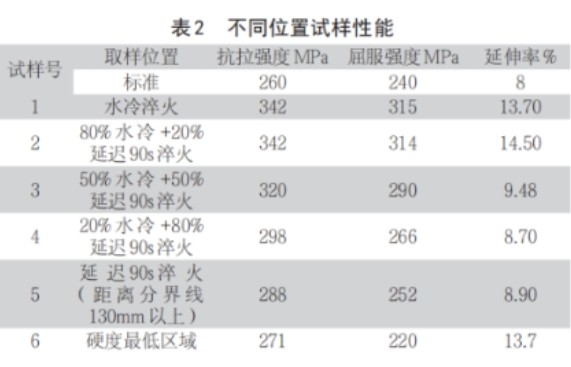

Itheyibhile 2 ibonisa iziphumo zovavanyo lwe-tensile olwenziwe kwiisampuli ezithathwe kwiindawo ezahlukeneyo zecandelo elihambelanayo. Inokufunyanwa ukuba amandla okuqina kunye namandla esivuno seNombolo ye-1 kunye neNombolo ye-2 phantse akukho tshintsho. Njengoko umlinganiselo wokulibaziseka kweziphelo zokucima ukhula, amandla okuqina kunye namandla emveliso yealloyi abonisa ukuhla okubalulekileyo. Nangona kunjalo, amandla okuqina kwindawo nganye yesampulu angaphezulu kwamandla aqhelekileyo. Kuphela kwindawo enobunzima obuphantsi, amandla esivuno aphantsi kunomgangatho wesampuli, ukusebenza kwesampuli akufanelekile.

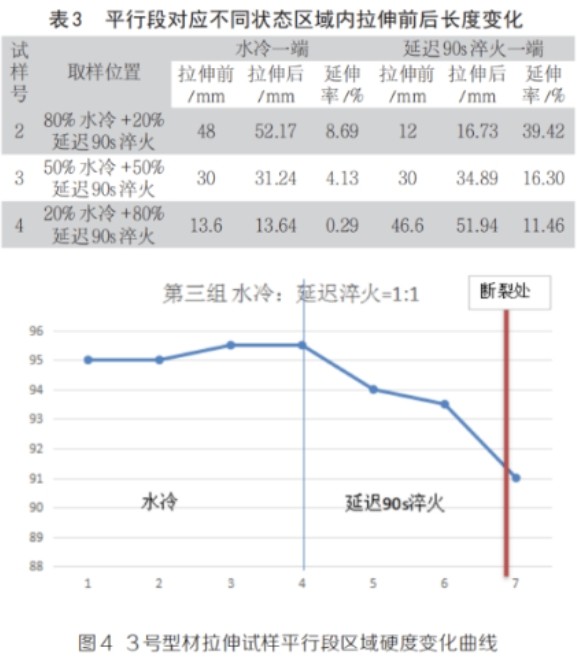

Umzobo we-4 ubonisa iziphumo zeempawu ze-tensile zesampula No. Ukuncipha kobulukhuni kubonisa ukuba ukusebenza kwesampuli kuncitshisiwe, kodwa ubunzima buyancipha ngokukhawuleza, buyancipha kuphela ukusuka kwi-95HB ukuya malunga ne-91HB ekupheleni kwecandelo elihambelanayo. Njengoko kunokubonwa kwiziphumo zokusebenza kwiThebhile yoku-1, amandla okuqina ehlile ukusuka kwi-342MPa ukuya kwi-320MPa yokupholisa amanzi. Ngelo xesha, kwafunyaniswa ukuba i-fracture point of the tensile sample is also end of the parallel section kunye nobunzima obuphantsi. Oku kungenxa yokuba kukude nokupholisa kwamanzi, ukusebenza kwe-alloy kuyancipha, kwaye isiphelo sifikelela kumda wamandla obunzima kuqala ukwenza i-necking phantsi. Ekugqibeleni, ikhefu ukusuka kwindawo ephantsi yokusebenza, kwaye indawo yekhefu ihambelana neziphumo zovavanyo lokusebenza.

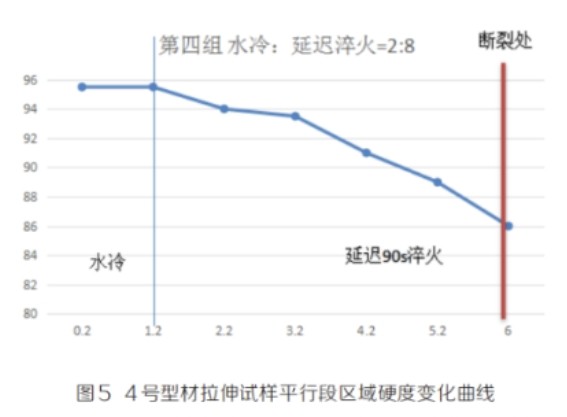

Umzobo we-5 ubonisa i-curve yobunzima becandelo elihambelanayo lesampuli ye-4 kunye ne-fracture position. Inokufunyanwa ukuba ukude ukusuka kumgca wokwahlula okupholisa amanzi, okuphantsi kobunzima bokuphela kokulibaziseka kokucima. Kwangaxeshanye, indawo yokwaphuka nayo ikwisiphelo apho ubunzima buphantsi, i-86HB fractures. Ukususela kwiThebhile 2, kufunyenwe ukuba akukho phantse akukho deformation yeplastiki ekupheleni kwamanzi apholileyo. Ukususela kwiThebhile 1, kufunyenwe ukuba isampuli yokusebenza (amandla e-tensile 298MPa, isivuno se-266MPa) iyancipha kakhulu. Amandla okuqina ngama-298MPa kuphela, angafikeleli kumandla esivuno sokuphela kwamanzi apholisekileyo (315MPa). Isiphelo senze intamo ephantsi xa ingaphantsi kwe-315MPa. Ngaphambi kokuphuka, kuphela i-elastic deformation eyenzekayo kwindawo epholileyo yamanzi. Njengoko uxinzelelo lwanyamalala, ukunyanzeliswa kwinqanaba lokupholisa amanzi kwanyamalala. Ngenxa yoko, inani le-deformation kwindawo yokupholisa amanzi kwiThebhile 2 phantse akukho tshintsho. Isampulu ikhefu ekupheleni komlilo wokulibaziseka komlilo, indawo ekhubazekileyo iyancitshiswa, kwaye ubunzima bokuphela buphantsi kakhulu, okubangela ukunciphisa okukhulu kwiziphumo zokusebenza.

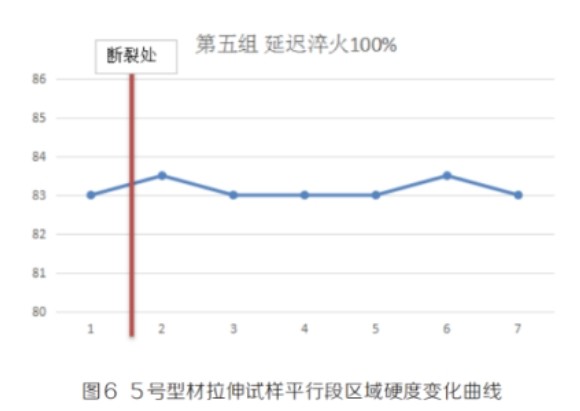

Thatha iisampulu kwindawo yokucima i-100% ebambezelekile ekupheleni komzekelo we-400mm. Umzobo 6 ubonisa igophe lobulukhuni. Ubunzima becandelo elihambelanayo liyancitshiswa malunga ne-83-84HB kwaye lizinzile. Ngenxa yenkqubo efanayo, ukusebenza kuphantse kufana. Akukho mzekelo ucacileyo ufunyenwe kwindawo yokuphuka. Ukusebenza kwe-alloy kuphantsi kunesampulu ecinywe ngamanzi.

Ukuze kuqhutyekwe nophononongo oluqhubekayo lwentsebenzo kunye nokwaphuka, icandelo elihambelanayo lomzekelo we-tensile wakhethwa kufutshane neyona ndawo iphantsi yobunzima (77HB). Ukususela kwiThebhile 1, kwafunyaniswa ukuba ukusebenza kuncitshiswe kakhulu, kwaye i-fracture point yabonakala kwindawo ephantsi yobunzima kwi-Figure 2.

2.3 Iziphumo zohlalutyo lwe-ANSYS

Umzobo we-7 ubonisa iziphumo ze-ANSYS ukulinganisa kwee-curves zokupholisa kwiindawo ezahlukeneyo. Ingabonwa ukuba ukushisa kwesampuli kwindawo yokupholisa amanzi kwehla ngokukhawuleza. Emva kwe-5s, ukushisa kwehle ukuya ngaphantsi kwe-100 ° C, kwaye kwi-80mm ukusuka kumgca wokuhlula, ubushushu behla malunga ne-210 ° C kwi-90s. Umyinge weqondo lokushisa ngu-3.5 ° C / s. Emva kwemizuzwana ye-90 kwindawo yokupholisa umoya we-terminal, iqondo lokushisa liyehla ukuya malunga ne-360 ° C, kunye nomlinganiselo wokuhla kwe-1.9 ° C / s.

Ngokusebenzisa uhlalutyo lokusebenza kunye neziphumo zokulinganisa, kufunyenwe ukuba ukusebenza kwendawo yokupholisa amanzi kunye nokucima ukulibaziseka kwendawo yindlela yokutshintsha eqala ukuhla kwaye inyuke kancinane. Ukuchaphazeleka ngokupholisa kwamanzi kufuphi nomgca wokwahlula, ukuqhutyelwa kobushushu kubangela ukuba isampuli kwindawo ethile yehle kwiqondo lokupholisa ngaphantsi kweyokupholisa kwamanzi (3.5 ° C / s). Ngenxa yoko, i-Mg2Si, eyaqina kwi-matrix, yanda kakhulu kule ndawo, kwaye ubushushu behla ukuya malunga ne-210 ° C emva kwemizuzwana engama-90. Isixa esikhulu seMg2Si esinemvula sikhokelela kwisiphumo esincinci sokupholisa kwamanzi emva kwe-90 s. Ubungakanani besigaba sokuqinisa i-Mg2Si esiye sancitshiswa emva kokunyangwa kokuguga sancitshiswa kakhulu, kwaye ukusebenza kwesampuli kuye kwancitshiswa. Nangona kunjalo, indawo yokucima ukulibaziseka kude kude nomgca wokwahlula ayichatshazelwa kancinci kukupholisa ubushushu bamanzi, kwaye i-alloy ipholisa kancinci phantsi kweemeko zokupholisa umoya (izinga lokupholisa i-1.9 ° C / s). Kuphela inxalenye encinci yesigaba seMg2Si ehla ngokukhawuleza, kwaye ubushushu bungama-360C emva kwe-90s. Emva kokupholisa kwamanzi, ininzi yesigaba seMg2Si sisekho kwi-matrix, kwaye iyahlakazeka kwaye iyancipha emva kokuguga, edlala indima yokomeleza.

3. Isiphelo

Kwafunyaniswa ngemifuniselo ukuba ukulibaziseka ukucima kuya kubangela ubulukhuni bendawo yokucima okulibazisekayo ekudibaneni kokucima okuqhelekileyo kunye nokulibaziseka kokucima ukuhla kuqala kwaye kunyuke kancinci de ekugqibeleni kuzinzile.

Kwi-alloy ye-6061 ye-aluminium, amandla e-tensile emva kokucima okuqhelekileyo kunye nokulibaziseka ukucinywa kwe-90 yi-342MPa kunye ne-288MPa ngokulandelelana, kwaye amandla esivuno yi-315MPa kunye ne-252MPa, zombini ezihlangabezana nemigangatho yokusebenza yesampuli.

Kukho ummandla onobulukhuni obuphantsi, obuncitshiswe ukusuka kwi-95HB ukuya kwi-77HB emva kokucima okuqhelekileyo. Ukusebenza apha kukwangowona uphantsi, unamandla okuqina angama-271MPa kunye namandla emveliso angama-220MPa.

Ngohlalutyo lwe-ANSYS, kwafunyaniswa ukuba izinga lokupholisa kweyona ndawo isezantsi yokusebenza kwindawo yokucima ukulibaziseka ye-90s yehle malunga ne-3.5 ° C ngesekhondi, okubangele ukungonelanga kwesisombululo esiqinileyo senqanaba lokomeleza iMg2Si. Ngokwale nqaku, kunokubonwa ukuba indawo yobungozi bokusebenza ibonakala kwindawo yokucima ukulibaziseka ekudibaneni kokucima okuqhelekileyo kunye nokulibaziseka kokucima, kwaye akukho kude ukusuka ekudibaneni, okubaluleke kakhulu ukukhokela ukugcinwa okufanelekileyo kwenkunkuma yenkqubo yokuphela komsila.

Ihlelwe nguMay Jiang esuka kwiMAT Aluminium

Ixesha lokuposa: Aug-28-2024