Ngexesha lenkqubo yokukhutshwa kwe-aluminium alloy extruded materials, ngakumbi iiprofayili ze-aluminium, i-"pitting" yesiphene ivame ukwenzeka phezu komhlaba. Ukubonakaliswa okuthe ngqo kubandakanya amathumba amancinci anobunzima obahlukeneyo, umsila, kunye nokuvakala kwesandla okucacileyo, kunye nemvakalelo e-spiky. Emva kwe-oxidation okanye unyango lwe-electrophoretic surface, bahlala bebonakala njengama-granules amnyama abambelela kumphezulu wemveliso.

Kwimveliso ye-extrusion yeeprofayili zecandelo elikhulu, esi siphene kunokwenzeka ukuba senzeke ngenxa yempembelelo yesakhiwo se-ingot, ubushushu be-extrusion, isantya se-extrusion, ubunzima bokubumba, njl. imveliso.

Kwisakhiwo esiqhelekileyo socango kunye neemveliso zeprofayili yefestile, abathengi ngokubanzi bamkela iziphene ezincinci zemingxuma, kodwa kwiiprofayili zemizi-mveliso ezifuna ugxininiso olulinganayo kwiipropati zoomatshini kunye nokusebenza kokuhombisa okanye ugxininiso olungakumbi ekusebenzeni kokuhombisa, abathengi ngokubanzi abasamkeli esi siphene, ngokukodwa iziphene ezifakwe emngxunyeni ezingahambelaniyo nombala wemvelaphi eyahlukileyo.

Ukuze uhlalutye indlela yokwakheka kweengqungquthela ezinqabileyo, i-morphology kunye nokubunjwa kweendawo ezineziphene phantsi kweendlela ezahlukeneyo ze-alloy kunye neenkqubo ze-extrusion zahlaziywa, kwaye ukungafani phakathi kweziphene kunye ne-matrix kuthelekiswa. Isisombululo esifanelekileyo sokusombulula ngokufanelekileyo amasuntswana arhabaxa sabekwa phambili, kwaye uvavanyo lwelingo lwenziwa.

Ukusombulula iziphene zokubeka iiprofayili, kuyimfuneko ukuqonda indlela yokwenza iziphene zokugoba. Ngexesha lenkqubo ye-extrusion, i-aluminiyam ebambelele kwibhanti yokusebenza ifa yeyona nto ibangela ukuba iziphene zokugoba kumphezulu wezinto ezikhutshiweyo ze-aluminium. Oku kungenxa yokuba inkqubo yokukhutshwa kwe-aluminiyam iqhutyelwa kwiqondo lokushisa eliphezulu malunga ne-450 ° C. Ukuba iziphumo zobushushu be-deformation kunye nobushushu be-friction zongezwa, ubushushu bentsimbi buya kuba phezulu xa buphuma kumngxuma wokufa. Xa imveliso iphuma kumngxuma wokufa, ngenxa yobushushu obuphezulu, kukho isenzeko se-aluminiyam enamathela phakathi kwentsimbi kunye nebhanti esebenzayo yokubumba.

Ifom yolu bhobhothi idla ngokuphindaphindiweyo: inkqubo ephindaphindiweyo yokudibanisa - ukukrazula - ukudibanisa - ukukrazula kwakhona, kwaye umkhiqizo uqhubela phambili, okubangelwa imigodi emincinci emininzi phezu komgangatho wemveliso.

Le nto yokudibanisa inxulumene nezinto ezifana nomgangatho we-ingot, imeko yomgangatho webhanti yokusebenza kwesikhunta, ukushisa kwe-extrusion, isantya se-extrusion, i-degree of deformation, kunye nokumelana nokuguqulwa kwesinyithi.

1 Izixhobo zovavanyo kunye neendlela

Ngophando lokuqala, sifunde ukuba izinto ezifana nokucoceka kwe-metallurgical, isimo sokungunda, inkqubo ye-extrusion, izithako, kunye neemeko zemveliso zinokuchaphazela amasuntswana omhlaba. Kuvavanyo, iintonga ezimbini ze-alloy, i-6005A kunye ne-6060, zisetyenziselwa ukukhupha icandelo elifanayo. I-morphology kunye nokubunjwa kweendawo ze-particle roughened zahlalutywa ngokusebenzisa i-spectrometer yokufunda ngokuthe ngqo kunye neendlela zokufumanisa i-SEM, kwaye xa kuthelekiswa ne-matrix eqhelekileyo ejikelezileyo.

Ukuze ukwahlula ngokucacileyo i-morphology yeziphene ezimbini ze-pitted kunye namasuntswana, zichazwa ngolu hlobo lulandelayo:

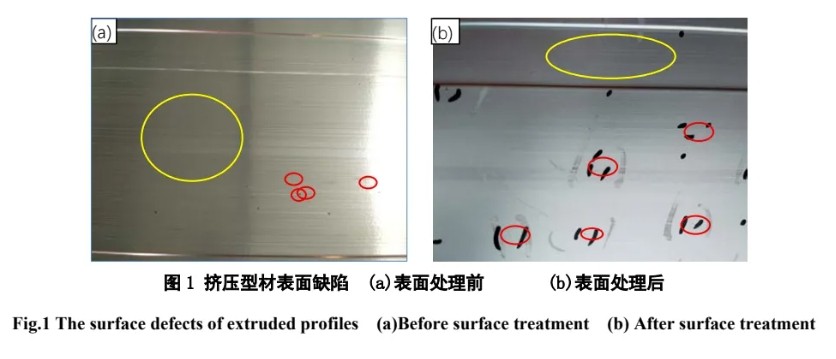

(1) Iziphene ezinemingxuma okanye iziphene zokutsalwa luhlobo oluthile lwesiphene esisisiphene esingaqhelekanga sokufana ne tadpole okanye esifana nenqaku esibonakala kumphezulu weprofayile. Isiphene siqala ukusuka kumgca wokukrala kwaye siphele ngesiphene siwela, siqokelele kwiimbotyi zetsimbi ekupheleni komgca wokukrala. Ubungakanani besiphene esinemingxuma ngokuqhelekileyo yi-1-5mm, kwaye ijika ibe mnyama mnyama emva konyango lwe-oxidation, echaphazela ekugqibeleni ukubonakala kweprofayili, njengoko kubonisiwe kwisangqa esibomvu kuMfanekiso 1.

(2) Amasuntswana angaphezulu abizwa ngokuba ziimbotyi zetsimbi okanye amasuntswana e-adsorption. Umphezulu weprofayili ye-aluminium ifakwe kwi-spherical grey-black hard metal particles kwaye inesakhiwo esikhululekile. Kukho iintlobo ezimbini zeeprofayili ze-aluminium alloy: ezo zinokucinywa kunye nezingenako ukucinywa. Ubungakanani ngokubanzi bungaphantsi kwe-0.5mm, kwaye buvakala burhabaxa xa ubamba. Akukho mkrwelo kwicandelo elingaphambili. Emva kwe-oxidation, ayahlukanga kakhulu kwi-matrix, njengoko kubonisiwe kwisangqa esityheli kuMfanekiso 1.

2 Iziphumo zovavanyo kunye nohlalutyo

2.1 Iziphene zokutsala umphezulu

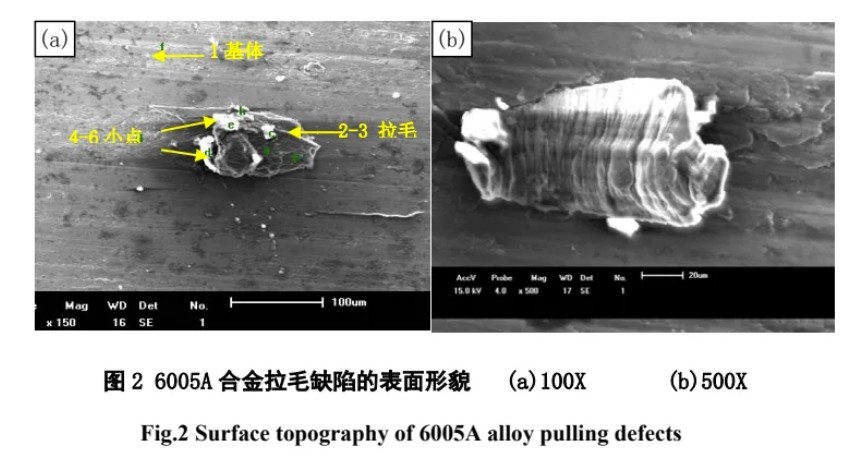

Umzobo we-2 ubonisa i-microstructural morphology yesiphene sokutsala ebusweni be-alloy ye-6005A. Kukho imikrwelo efana nenyathelo kwindawo engaphambili yokutsalwa, kwaye iphetha ngamaqhuqhuva apakishweyo. Emva kokuvela kwamaqhuqhuva, umphezulu ubuyela kwindawo eqhelekileyo. Indawo ye-roughening defect ayigudi kwi-touch, inovakalelo olubukhali olunameva, kwaye ibambelela okanye iqokelele kumphezulu weprofayili. Ngokusebenzisa uvavanyo lwe-extrusion, kwabonwa ukuba i-morphology yokutsala ye-6005A kunye ne-6060 yeeprofayili ezigqithisiweyo zifana, kwaye umsila wemveliso ungaphezulu kwentloko; Umahluko kukuba ubungakanani bokutsala bubonke be-6005A buncinci kwaye ubunzulu bomkrwelo bubuthathaka. Oku kunokunxulunyaniswa notshintsho ekubunjweni kwe-alloy, imeko yentonga, kunye neemeko zokungunda. Ukujongwa phantsi kwe-100X, kukho amanqaku acacileyo okukrala kwisiphelo sangaphambili sendawo yokutsala, eyandiswe ecaleni kwendlela yokuphuma, kwaye imilo yamasuntswana amaqhuqhuva okugqibela ayiqhelekanga. Kwi-500X, isiphelo sangaphambili somphezulu wokutsala sinezinyathelo ezinjengomkrwelo ecaleni kwendlela ye-extrusion (ubukhulu besi siphene malunga ne-120 μm), kwaye kukho iimpawu ezicacileyo zokupakisha kwiinqununu ze-nodular ekupheleni komsila.

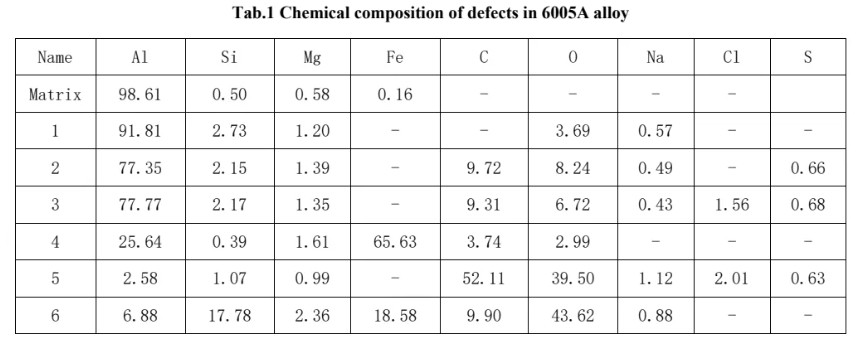

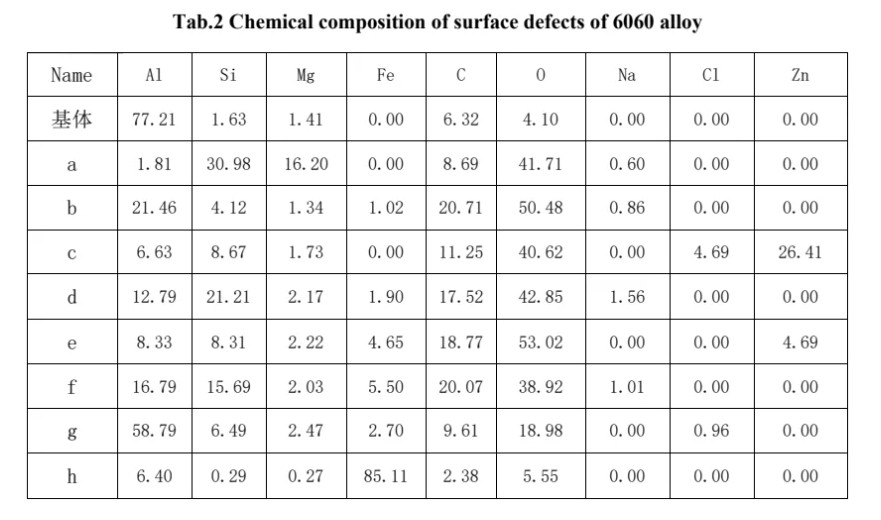

Ukuze uhlalutye izizathu zokutsala, i-spectrometer yokufunda ngokuthe ngqo kunye ne-EDX zisetyenziselwa ukwenza uhlalutyo lwamacandelo kwiindawo eziphosakeleyo kunye ne-matrix yamacandelo amathathu e-alloy. Itheyibhile 1 ibonisa iziphumo zovavanyo lweprofayili ye-6005A. Iziphumo ze-EDX zibonisa ukuba ukubunjwa kwendawo yokubeka i-stacking particles edonsa ngokusisiseko kufana ne-matrix. Ukongeza, amanye amasuntswana okungcola aqokelelwa ngaphakathi najikeleze isiphene sokutsala, kwaye amasuntswana okungcola aqukethe iC, O (okanye iCl), okanye iFe, Si, kunye neS.

Uhlalutyo lweziphene ezibukhali ze-6005A zeprofayili ze-oxidized extruded ezintle zibonisa ukuba iinqununu zokutsala zikhulu ngobukhulu (1-5mm), umphezulu uxakeke kakhulu, kwaye kukho i-step-like scratches kwicandelo elingaphambili; Ukuqulunqwa kusondele kwi-matrix ye-Al, kwaye kuya kubakho izigaba ezingafaniyo eziqulethe i-Fe, i-Si, i-C, kunye ne-O esasazwa ngeenxa zonke kuyo. Ibonisa ukuba ukutsalwa kwendlela yokwakheka kwee-alloys ezintathu kuyafana.

Ngethuba lenkqubo ye-extrusion, i-friction flow friction iya kubangela ukuba ukushisa kwebhanti yokusebenza kwe-mold kuphakame, yenze "i-aluminium enamathelayo" kwinqanaba lokusika lokungena kwebhanti yokusebenza. Ngelo xesha, ukugqithisa kwe-Si kunye nezinye izinto ezifana ne-Mn kunye ne-Cr kwi-alloy ye-aluminium kulula ukwenza izisombululo ezitshintshileyo eziqinileyo kunye ne-Fe, eziza kukhuthaza ukusekwa "kwe-aluminium encamathelayo" ekungeneni kwendawo yokusebenza yokubumba.

Njengoko isinyithi siqhubela phambili kwaye sixubha kwibhanti yomsebenzi, into ehambelanayo ye-bonding-tearing-bonding eqhubekayo yenzeke kwindawo ethile, ebangela ukuba isinyithi siqhubekele phambili kule ndawo. Xa amasuntswana enyuka ukuya kubukhulu obuthile, Iya kutsalwa yimveliso equkuqelayo kwaye yenze iimpawu zokukrala kumphezulu wesinyithi. Iya kuhlala phezu komhlaba wesinyithi kwaye yenze iincinci zokutsala ekupheleni kokukrala. ke ngoko, kunokuqwalaselwa ukuba ukubunjwa kwamasuntswana arhabaxa kunxulumene ikakhulu ne-aluminiyam enamathela kwibhanti yokusebenza komngundo. Izigaba ezingafaniyo ezisasazwa ngeenxa zonke zinokuthi zivela kwi-oyile yokuthambisa, i-oxides okanye amasuntswana othuli, kunye nokungcola okulethwe ngumhlaba onqabileyo we-ingot.

Nangona kunjalo, inani lokutsalwa kwiziphumo zovavanyo ze-6005A lincinci kwaye idigri ilula. Ngakolunye uhlangothi, kungenxa ye-chamfering ekuphumeni kwebhanti yokusebenza kwe-mold kunye nokupholisa ngononophelo kwebhanti elisebenzayo ukunciphisa ubukhulu bomgangatho we-aluminium; kwelinye icala, inxulumene nomxholo weSi ogqithisileyo.

Ngokweziphumo zokufunda ngokuthe ngqo ukubunjwa kwe-spectral, kunokubonwa ukuba ukongeza kwi-Si edibeneyo ne-Mg Mg2Si, i-Si eseleyo ibonakala ngendlela yento elula.

2.2 Amasuntswana amancinane kumphezulu

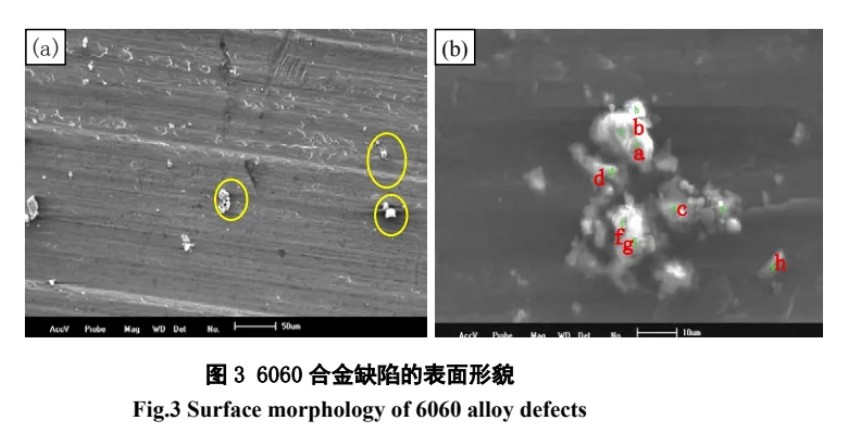

Ngaphantsi kokuhlolwa okubonakalayo okuphantsi kokuphakama, iincinci zincinci (≤0.5mm), azilulanga kwi-touch, zinemvakalelo ebukhali, kwaye zibambelele kumphezulu weprofayili. Ukuqwalaselwa phantsi kwe-100X, iincinci ezincinci kumphezulu zisasazwa ngokungacwangciswanga, kwaye kukho iincinci ezincinci ezifakwe kumphezulu kungakhathaliseki ukuba kukho imikrwelo okanye cha;

Kwi-500X, kungakhathaliseki ukuba kukho imikrwelo ecacileyo efana nenyathelo kumphezulu ecaleni kwendlela ye-extrusion, amasuntswana amaninzi asaqhotyoshelwe, kwaye ubungakanani bamasuntswana ayahluka. Ubukhulu becala bukhulu malunga ne-15 μm, kwaye iincinci ezincinci zi malunga ne-5 μm.

Ngokusebenzisa uhlalutyo lokubunjwa kwe-6060 ye-alloy surface particles kunye ne-matrix engaguqukiyo, iinqununu ziqulunqwe kakhulu yi-O, C, Si, kunye ne-Fe, kwaye umxholo we-aluminium uphantsi kakhulu. Phantse onke amasuntswana aqulethe i-O kunye no-C. Ukwakheka kwesuntswana ngalinye kwahluke kancinane. Phakathi kwazo, iinqununu zisondele kwi-10 μm, ephakamileyo kakhulu kune-matrix Si, Mg, kunye ne-O; Ngo-c amasuntswana, uSi, O, kunye noCl ngokucacileyo aphezulu; Amacandelo d kunye no-f aqulathe iSi, O, kunye neNa; amasuntswana e aqulathe uSi, Fe, kunye no-O; Amasuntswana e-h aqulethe iikhompawundi ezine-Fe. Iziphumo ze-6060 particles zifana nale nto, kodwa ngenxa yokuba umxholo we-Si kunye ne-Fe kwi-6060 ngokwayo iphantsi, iziqulatho ezihambelana ne-Si kunye ne-Fe kwiindawo eziphantsi komhlaba nazo ziphantsi; Umxholo we-C kwiinqununu ze-6060 uphantsi.

Amasuntswana omphezulu asenokungabi ngamasuntswana amancinane, kodwa anokubakho ngokohlobo lokudityaniswa kwamasuntswana amaninzi aneemilo ezahlukeneyo, kunye neepesenti zobunzima beelementi ezahlukeneyo kumasuntswana ahlukeneyo. Kukholelwa ukuba amasuntswana ikakhulu aqulunqwe ziindidi ezimbini. Enye i-precipitates efana ne-AlFeSi kunye ne-elemental Si, ephuma kwizigaba eziphezulu zokunyibilika zokungahlambuluki ezifana ne-FeAl3 okanye i-AlFeSi (Mn) kwi-ingot, okanye izigaba ze-precipitate ngexesha lenkqubo ye-extrusion. Omnye ngumba wangaphandle obambeleyo.

2.3 Isiphumo sokurhabaxa komphezulu we-ingot

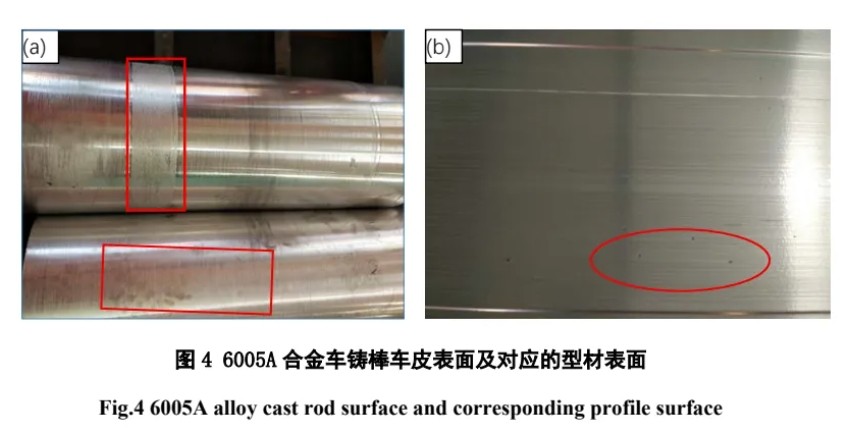

Ngethuba lovavanyo, kwafunyaniswa ukuba indawo yangasemva ye-6005A ye-lathe ye-cast rod yayinzima kwaye inothuli. Kwakukho iintonga ezimbini eziphosiweyo ezinezixhobo ezinzulu zokuguqula iimpawu kwiindawo zendawo, ezihambelana nokunyuka okuphawulekayo kwinani lokutsalwa emva kokukhutshwa, kunye nobukhulu bomtsalane omnye bukhulu, njengoko kuboniswe kuMfanekiso 7.

Intonga ye-6005A ayinayo i-lathe, ngoko uburhabaxa bomphezulu buphantsi kwaye inani lokutsalwa liyancipha. Ukongezelela, ekubeni akukho manzi okusika okugqithisileyo aqhotyoshelwe kumanqaku e-lathe yentonga yokuphosa, umxholo we-C kwiinqununu ezihambelanayo ziyancitshiswa. Kungqiniwe ukuba ukujika kwamanqaku kumphezulu wentonga ephosiweyo kuya kwandisa ukutsala kunye nokwakheka kwamasuntswana kwinqanaba elithile.

3 Ingxubusho

(1) Amacandelo okutsala iziphene ngokusisiseko ziyafana nezo ze-matrix. Ngamasuntswana angaphandle, ulusu oludala kumphezulu we-ingot kunye nezinye izinto ezingcolileyo eziqokelelwe kwi-extrusion barrel wall okanye indawo efileyo yesikhunta ngexesha lenkqubo ye-extrusion, eziswa kwindawo yesinyithi okanye i-aluminium layer yebhanti yokusebenza kwe-mold. Njengoko imveliso ihamba phambili, imikrwelo yomhlaba ibangelwa, kwaye xa imveliso iqokelelana ukuya kubungakanani obuthile, ithathwa yimveliso ukwenza ukutsala. Emva kwe-oxidation, ukutsalwa kwakudliwe, kwaye ngenxa yobukhulu bayo obukhulu, kwakukho iziphene ezinjengomgodi apho.

2 Ukubunjwa kwabo ngokucacileyo kwahlukile kuleyo ye-matrix, kwaye ikakhulu iqulethe i-O, C, Fe, kunye ne-Si element. Amanye amasuntswana alawulwa ngu-O no-C, kwaye amanye amasuntswana alawulwa ngu-O, C, Fe, kunye noSi. Ngoko ke, kuqikelelwa ukuba amaqhekeza angaphezulu avela kwimithombo emibini: enye i-precipitates efana ne-AlFeSi kunye ne-elemental Si, kunye nokungcola okufana no-O kunye no-C kunamathele kumphezulu; Omnye ngumba wangaphandle obambeleyo. Amasuntswana adla ngokutya emva kwe-oxidation. Ngenxa yobukhulu bawo buncinci, abanayo okanye impembelelo encinci kumphezulu.

(3) Amacandelo atyebileyo kwiimpawu ze-C kunye ne-O ikakhulu zivela kwioli yokuthambisa, uthuli, umhlaba, umoya, njl njl. Izinto eziphambili zeoli yokuthambisa ziyi-C, O, H, S, njl., kunye neyona nto iphambili yothuli kunye nomhlaba yiSiO2. Umxholo we-O wamasuntswana omphezulu uphezulu. Ngenxa yokuba amasuntswana akwimeko yobushushu obuphezulu ngoko nangoko emva kokushiya ibhanti elisebenzayo, kwaye ngenxa yendawo enkulu ethile yommandla wamasuntswana, abhengeza ngokulula ii-athomu ze-O emoyeni kwaye abangele i-oxidation emva kokunxibelelana nomoya, okukhokelela kumxholo ophezulu we-O kune-matrix.

(4) I-Fe, i-Si, njl. ikakhulukazi ivela kwi-oxides, isikali esidala kunye nezigaba zokungcola kwi-ingot (indawo ephezulu yokunyibilika okanye isigaba sesibini esingapheliswanga ngokupheleleyo yi-homogenization). I-Fe element ivela kwi-Fe kwii-ingots ze-aluminium, zenza izigaba zokungcola okuphezulu kwe-melting ezifana ne-FeAl3 okanye i-AlFeSi (Mn), engenakuchithwa kwisisombululo esiqinileyo ngexesha lenkqubo ye-homogenization, okanye ingaguquki ngokupheleleyo; I-Si ikhona kwi-matrix ye-aluminium ngendlela ye-Mg2Si okanye isisombululo esiqinileyo esiphezulu se-Si ngexesha lenkqubo yokuphosa. Ngexesha lenkqubo eshushu yokukhupha intonga ephosiweyo, u-Si ogqithisayo unokunyuka. I-solubility ye-Si kwi-aluminium yi-0.48% kwi-450 ° C kunye ne-0.8% (wt%) kwi-500 ° C. Isiqulatho se-Si esingaphezulu kwe-6005 malunga ne-0.41%, kwaye i-Si eqikelelweyo ingaba yi-aggregation kunye nemvula ebangelwa ukuguquguquka koxinzelelo.

(5) I-Aluminiyam enamathele kwibhanti yokusebenza kwe-mold iyona nto ibangela ukutsala. I-extrusion die yindawo yokushisa ephezulu kunye noxinzelelo oluphezulu. I-Metal flow friction iya kwandisa ubushushu bebhanti yokusebenza yesikhunta, yenze "i-aluminium enamathelayo" kwinqanaba lokusika lokungena kwebhanti yokusebenza.

Ngelo xesha, ukugqithisa kwe-Si kunye nezinye izinto ezifana ne-Mn kunye ne-Cr kwi-alloy ye-aluminium kulula ukwenza izisombululo ezitshintshileyo eziqinileyo kunye ne-Fe, eziza kukhuthaza ukusekwa "kwe-aluminium encamathelayo" ekungeneni kwendawo yokusebenza yokubumba. Intsimbi ehamba "kwi-aluminium encamathelayo" yeyokukhuhlana kwangaphakathi (i-sliding shear ngaphakathi kwesinyithi). I-metal deforms kwaye ilukhuni ngenxa yokungqubuzana kwangaphakathi, okukhuthaza isinyithi esisezantsi kunye nokubumba ukuba kunamathele kunye. Ngelo xesha, i-mold belt esebenza ngebhanti ikhubazekile ibe yimo yexilongo ngenxa yoxinzelelo, kunye ne-aluminium enamathele eyenziwe yi-cut cut edge yebhanti esebenzayo edibanisa iphrofayili ifana nomgca wokusika isixhobo sokuguqula.

Ukwenziwa kwe-aluminiyam encangathi yinkqubo eguqukayo yokukhula kunye nokuchithwa. Amacandelo ahlala ekhutshwa yiprofayili.Ukubambelela kumphezulu weprofayili, ukwenza iziphene zokutsala. Ukuba igeleza ngokuthe ngqo kwibhanti yomsebenzi kwaye ifakwe ngokukhawuleza kwiprofayili, iincinci ezincinci ezifakwe kwi-thermal ebusweni zibizwa ngokuthi "i-adsorption particles". Ukuba ezinye iinqununu ziya kuphulwa yi-alloy ye-aluminium ekhutshweyo, ezinye iinqununu ziya kubambelela kumphezulu webhanti yomsebenzi xa zidlula ibhanti lomsebenzi, zibangela imikrwelo ebusweni beprofayili. Isiphelo somsila yimatrix epakiweyo yealuminiyam. Xa kukho i-aluminiyam eninzi enamathele phakathi kwebhanti yomsebenzi (ibhondi yomelele), iya kuyenza ibe mandundu imikrwelo yomhlaba.

(6) Isantya se-extrusion sinempembelelo enkulu ekutsaleni. Impembelelo yesantya se-extrusion. Ngokubhekiselele kwi-alloy ye-6005 elandelwayo, isantya se-extrusion sinyuka ngaphakathi koluhlu lovavanyo, ukushisa kwe-outlet kuyanda, kwaye inani leengqungquthela zokutsalwa komhlaba landa kwaye liba nzima njengoko imigca yomatshini isanda. Isantya se-extrusion kufuneka sigcinwe ngokuzinza kangangoko kunokwenzeka ukuphepha utshintsho olukhawulezayo kwisantya. Isantya esigqithisekileyo sokukhupha kunye nobushushu obuphezulu bokukhutshwa kuya kukhokelela ekwandeni kokhuhlane kunye nokutsalwa kwamasuntswana. Indlela ethile yempembelelo yesantya se-extrusion kwi-phenomenon yokutsala idinga ukulandelwa okulandelayo kunye nokuqinisekiswa.

(7) Umgangatho ophezulu wentonga ephosiweyo nayo yinto ebalulekileyo echaphazela iinqununu zokutsala. Umphezulu wentonga ye-cast cast i-rough, kunye ne-sawing burrs, i-oil stains, uthuli, i-corrosion, njl., Konke oko kwandisa ukuthambekela kokutsala amaqhekeza.

4 Isiphelo

(1) Ukubunjwa kweziphene zokutsala kuhambelana nelo matrix; Ukubunjwa kwendawo yamasuntswana ngokucacileyo kwahlukile kuleyo ye-matrix, ikakhulu iqulethe i-O, C, Fe, kunye ne-Si element.

(2) Ukutsala i-particle defects kubangelwa ikakhulu yi-aluminium enamathele kwibhanti yokusebenza kwe-mold. Naziphi na izinto ezikhuthaza ukuba i-aluminiyam ibambelele kwibhanti yokusebenza yokubumba iya kubangela ukutsala iziphene. Kwisiseko sokuqinisekisa umgangatho wentonga etyhidiweyo, isizukulwana sokutsala iinqununu asinayo impembelelo ethe ngqo kwi-alloy composition.

(3) Unyango olufanelekileyo lomlilo olufanelekileyo lunenzuzo ekunciphiseni ukutsalwa komhlaba.

Ixesha lokuposa: Sep-10-2024