Icandelo.1 uyilo olunengqiqo

Ukubumba ubukhulu becala kuyilwe ngokweemfuno zokusetyenziswa, kwaye isakhiwo sayo ngamanye amaxesha asinakuba singqiqweni ngokupheleleyo kwaye silingane. Oku kufuna ukuba umyili athathe amanyathelo asebenzayo xa eyila isikhunta ngaphandle kokuchaphazela ukusebenza kwesikhunta, kwaye uzame ukunikela ingqalelo kwinkqubo yokuvelisa, ingqiqo yesakhiwo kunye ne-symmetry yobume bejometri.

(1) Zama ukuphepha iikona ezibukhali kunye namacandelo anomahluko omkhulu wobunzima

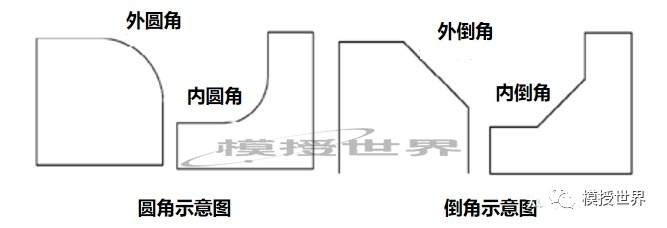

Kufuneka kubekho utshintsho olugudileyo ekudibaneni kwamacandelo ashinyeneyo nabhityileyo okungunda. Oku kunokunciphisa ngokufanelekileyo ukuhluka kweqondo lokushisa kwi-cross-section of the mold, ukunciphisa uxinzelelo lwe-thermal, kwaye ngexesha elifanayo ukunciphisa ukungabikho kwexesha lokuguqulwa kwezicubu kwi-cross-section, kunye nokunciphisa uxinzelelo lwezicubu. Umzobo we-1 ubonisa ukuba i-mold ithatha i-fillet yenguqu kunye ne-cone yokutshintsha.

(2) Ukwandisa ngokufanelekileyo imingxuma yenkqubo

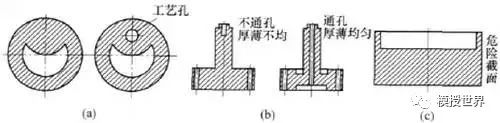

Kwezinye iimbumba ezingenakuqinisekisa i-uniform kunye ne-symmetrical cross cross section, kuyimfuneko ukutshintsha i-non-through hole ibe ngumngxuma okanye ukwandisa imingxuma yenkqubo ngokufanelekileyo ngaphandle kokuchaphazela ukusebenza.

Umzobo we-2a ubonisa ukufa kunye nomngxuma omxinwa, oya kuphazamiseka njengoko kuboniswe ngumgca wamachaphaza emva kokucima. Ukuba imingxuma emibini yenkqubo inokongezwa kwi-design (njengoko kuboniswe kuMzobo 2b), ukuhluka kweqondo lokushisa kwinqanaba elinqamlezayo ngexesha lokucima kuncitshisiwe, uxinzelelo lwe-thermal luyancitshiswa, kwaye i-deformation iphuculwe kakhulu.

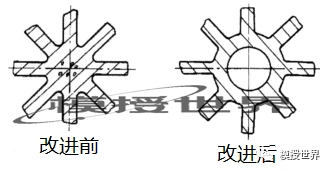

(3) Sebenzisa izakhiwo ezivaliweyo kunye ne-symmetrical kangangoko kunokwenzeka

Xa imilo yesikhunta ivulekile okanye i-asymmetrical, ukusabalalisa uxinzelelo emva kokucima akulingani kwaye kulula ukuguqula. Ke ngoko, kwizibungu zombhobho oguqukayo ngokubanzi, ukuqinisa kufuneka kwenziwe ngaphambi kokucima, kwaye emva koko kunqunyulwe emva kokucima. I-workpiece ye-trough eboniswe kwi-Figure 3 yayinokukhubazeka ekuqaleni kwi-R emva kokucima, kwaye yaqiniswa (inxalenye eqanduselweyo kwi-Figure 3), inokuthintela ngokufanelekileyo ukucima i-deformation.

4

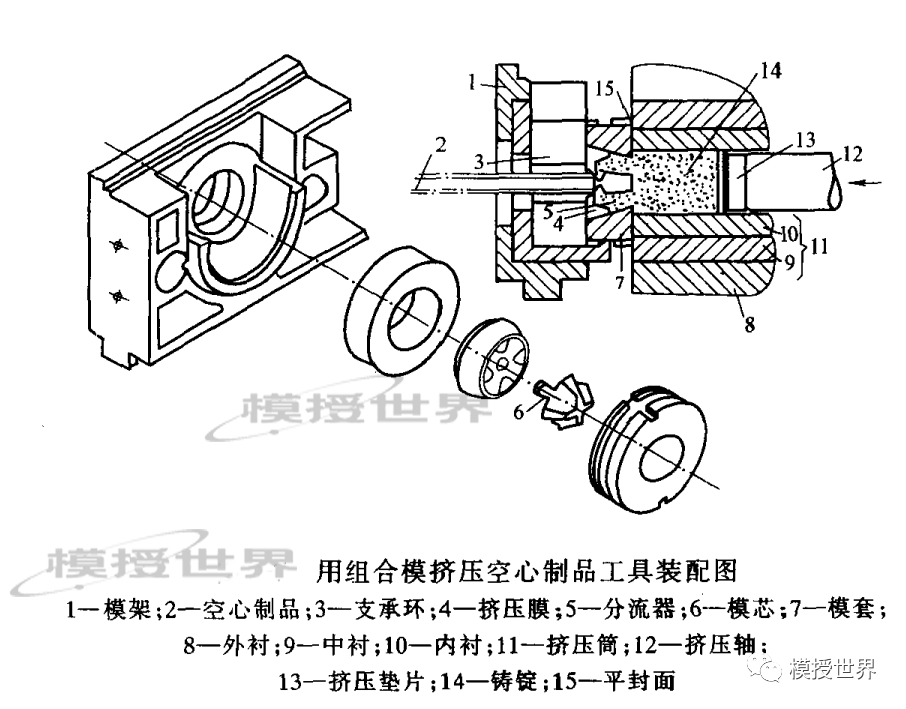

Kuba enkulu ifa kunye nemilo enzima kunye nobukhulu> 400mm kunye neepuntshi ezinobunzima obuncinci kunye nobude obude, kukulungele ukwamkela isakhiwo esidibeneyo, ukwenza lula ukudibanisa, ukunciphisa ubukhulu obuncinci, kunye nokuguqula indawo yangaphakathi yokubumba kwindawo yangaphandle, engafanelekanga kuphela ukufudumeza kunye nokupholisa.

Xa uyila ulwakhiwo oludityanisiweyo, kufuneka luboliswe ngokubanzi ngokwemigaqo elandelayo ngaphandle kokuchaphazela ukuchaneka kokufaneleka:

- Lungisa ubukhulu ukwenzela ukuba i-cross-section ye-mold kunye ne-cross-sections ehluke kakhulu iyinto efanayo emva kokubola.

- Ukubola kwiindawo apho uxinezeleko kulula ukuluvelisa, lusasaze uxinzelelo lwalo, kwaye luthintele ukuqhekeka.

- Sebenzisana nomngxuma wenkqubo ukwenza ulwakhiwo lube-symmetrical.

- Kukulungele ukusetyenzwa okubandayo kunye nokutshisa kwaye kulula ukudibanisa.

- Eyona nto ibalulekileyo kukuqinisekisa ukusebenziseka.

Njengoko kubonisiwe kuMfanekiso 4, kukufa okukhulu. Ukuba ulwakhiwo oludibeneyo luyamkelwa, kungekhona nje unyango lobushushu luya kuba nzima, kodwa kwakhona i-cavity iya kuncipha ngokungahambi kakuhle emva kokucima, kwaye ibangele ukungalingani kunye nokuphazamiseka kwendiza ye-cut cut, eya kuba nzima ukuyilungisa kwi-processing elandelayo. , ngoko ke, isakhiwo esidibeneyo sinokumkelwa. Ngokomgca onamachaphaza kuMzobo we-4, uhlukaniswe ube ngamacandelo amane, kwaye emva kokunyangwa kobushushu, bahlanganiswe kwaye baqulunqwe, kwaye emva koko baphantsi kwaye bahambelana. Oku akugcini nje ukwenza lula unyango lobushushu, kodwa kwakhona kusombulula ingxaki deformation.

Icandelo.2 ukhetho oluchanekileyo lwemathiriyeli

I-deformation yonyango lokushisa kunye nokuqhekeka kuhambelana ngokusondeleyo nentsimbi esetyenzisiweyo kunye nomgangatho wayo, ngoko kufuneka kusekelwe kwiimfuno zokusebenza kwesikhunta. Ukhetho olunengqiqo lwensimbi kufuneka luthathele ingqalelo ukuchaneka, ukwakheka kunye nobukhulu besikhunta, kunye nendalo, ubuninzi kunye neendlela zokucubungula izinto ezicutshungulwayo. Ukuba i-mold jikelele ayinayo i-deformation kunye neemfuno ezichanekileyo, i-carbon tool steel ingasetyenziselwa ngokwemiqathango yokunciphisa iindleko; iindawo ezinokukhubazeka ngokulula kunye neziqhekekileyo, intsimbi yesixhobo sealloyi esinamandla aphezulu kunye nokucima okucothayo okubalulekileyo kunye nesantya sokupholisa sinokusetyenziswa; Ngokomzekelo, icandelo lombane lifa ekuqaleni lisetyenziswe i-T10A yentsimbi, i-deformation enkulu kunye nokulula ukukrazula emva kokucinywa kwamanzi kunye nokupholisa kweoli, kunye ne-alkali bath quenching cavity akukho lula ukwenza lukhuni. Ngoku sebenzisa intsimbi ye-9Mn2V okanye i-CrWMn yensimbi, ubunzima bokucima kunye nokuguqulwa kunokuhlangabezana neemfuno.

Ingabonwa ukuba xa ukuguqulwa kwesikhunta esenziwe ngentsimbi ye-carbon ayihambelani neemfuno, kuseyindleko-esebenzayo ukusebenzisa i-alloy steel efana ne-9Mn2V steel okanye i-CrWMn steel. Nangona ixabiso lezinto eziphathekayo liphezulu kancinci, ingxaki ye-deformation kunye nokuqhekeka isonjululwe.

Ngelixa ukhetha izinto ngokuchanekileyo, kuyafuneka ukuba kuqiniswe ukuhlolwa kunye nokulawulwa kwezixhobo zokuthintela ukuqhekeka konyango lobushushu ngenxa yeziphene.

Ihlelwe nguMay Jiang esuka kwiMAT Aluminium

Ixesha lokuposa: Sep-16-2023