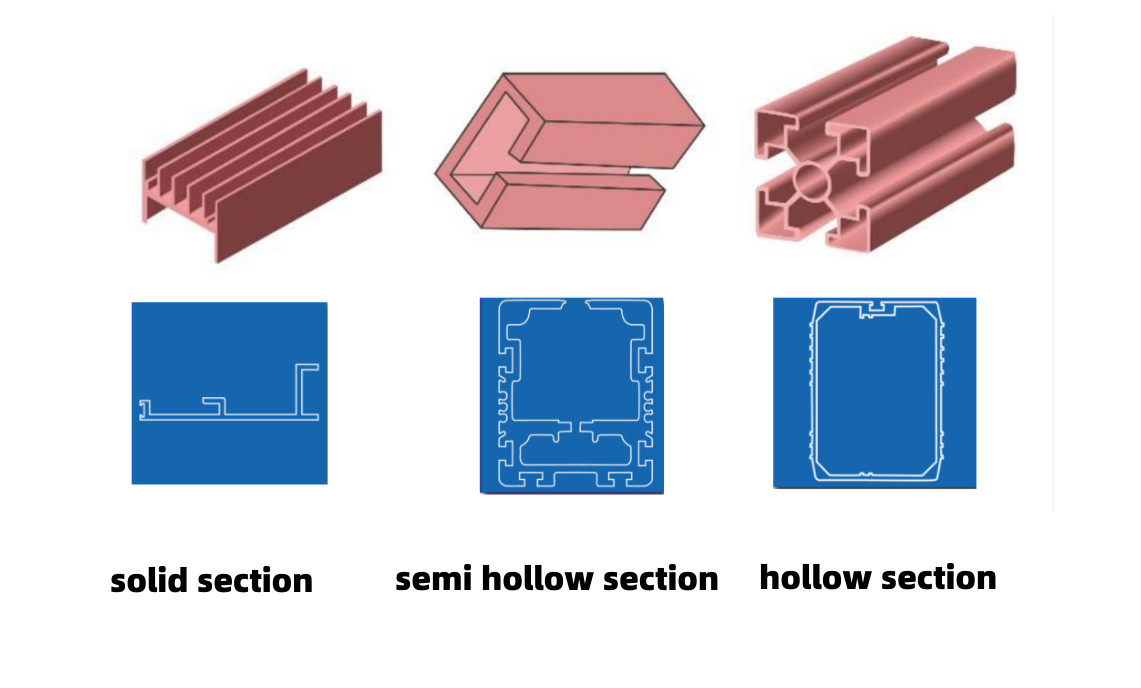

Icandelo le-aluminiyam extrusion lahlulwe ngokweendidi ezintathu:

Icandelo eliqinileyo: ixabiso eliphantsi lemveliso, ixabiso eliphantsi lokungunda

Icandelo elingenamgongxo: ukungunda kulula ukunxiba kunye nokukrazula kunye nokuphuka, kunye neendleko eziphezulu zemveliso kunye neendleko zokungunda

Icandelo elingenanto: ixabiso eliphezulu lemveliso kunye nexabiso lokungunda, ixabiso eliphezulu lokungunda kwiimveliso ezinqabileyo

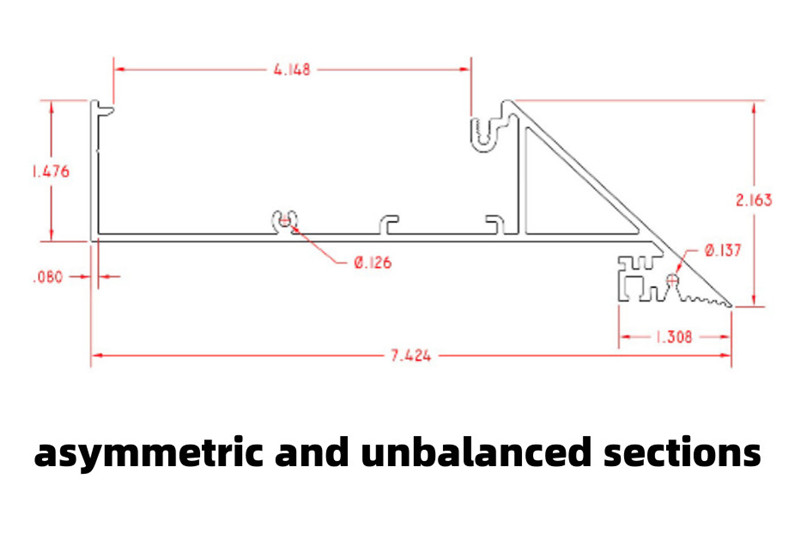

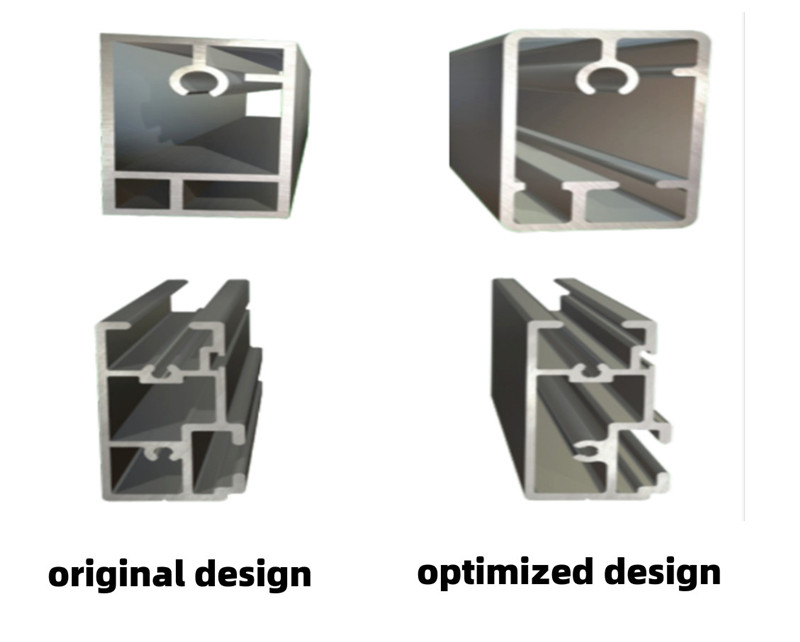

1.Kuphephe amacandelo asymmetrical kunye namacandelo angalinganiyo

Amacandelo e-asymmetric kunye namacandelo angalinganiyo anyusa ubunzima be-extrusion, kwaye kwangaxeshanye, iingxaki ezisemgangathweni ziyakwazi ukwenzeka, njengokuchaneka komgangatho kunye nokuqina kunzima ukuqinisekisa, ukugoba kunye nokujija kwamacandelo, ukusebenza kakuhle kwemveliso ephantsi, kunye nokubumba kulula ukunxiba kunye nokukrazula ngexesha lokuvelisa ngobuninzi.

Ubuninzi be-asymmetric okanye ukungalingani kwecandelo le-aluminium extrusion, kunzima ngakumbi ukuqinisekisa ukuchaneka, i-angle kunye nokunye ukuchaneka kwe-dimensional.

Nangona iimilo ze-asymmetrical kunye nezingalinganiyo zinokuveliswa, isinyithi asinakukwazi ukuhamba kwiindawo ezincinci kunye nezingaqhelekanga ngexesha lokukhupha, apho ukuphazamiseka okanye eminye imiba yekhwalithi ingenzeka lula.

Kwakhona, nokuba kunokwenzeka ukukhupha iimilo ze-asymmetric kunye nezingalinganiyo, iindleko eziphezulu zezixhobo kunye neendleko eziphezulu zokuvelisa ngenxa yezantya ezicothayo zokukhupha, ekugqibeleni zikhokelela kwiindleko eziphezulu zokubumba kunye neendleko zokuvelisa.

Inani elikhulu lamacala kunye namashaneli kwiprofayili ye-extrusion, iya kuba ichanekile kwaye ibiza kakhulu.

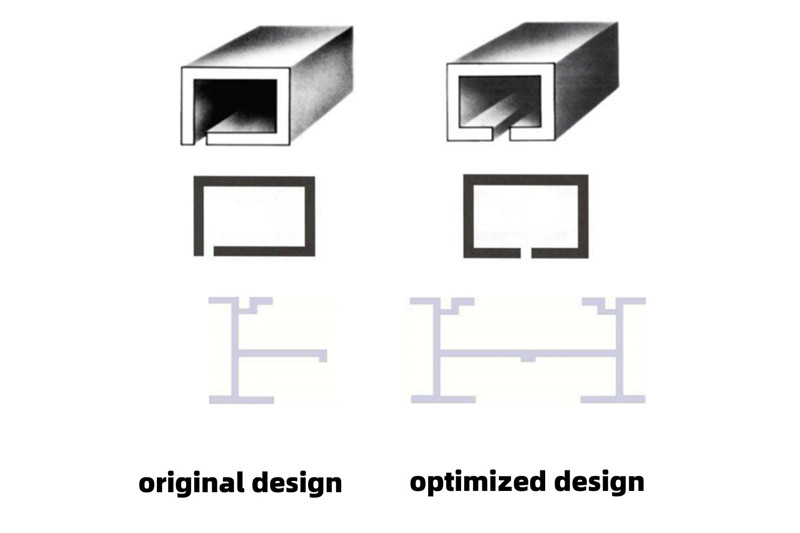

2.Ilula imilo yecandelo, ingcono

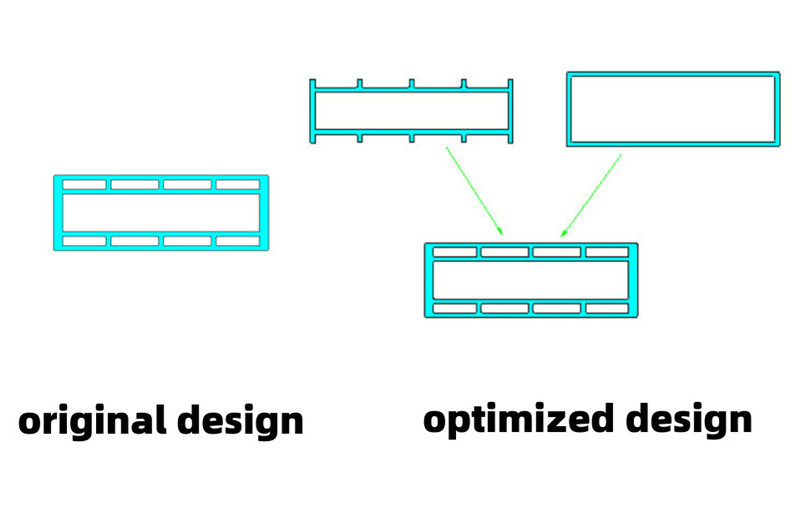

Ezinye iinjineli zoyilo lwemveliso ziyila izinto ezininzi kakhulu kwi-aluminiyam extrusion. Nangona inzuzo ekhethekileyo ye-aluminiyam extrusions kukongeza imingxuma, iindawo zokubeka okanye abaphathi be-screw kwicandelo, kuya kukhokelela kuyilo olunzima kakhulu lokungunda, okanye alunakugqithiswa kwaphela kunye neendleko zemveliso ezibiza kakhulu.

Xa icandelo le-extrusion linzima kakhulu, linokucingwa ukuba lisebenzise iinxalenye ezimbini okanye ngaphezulu kwi-extrusion.

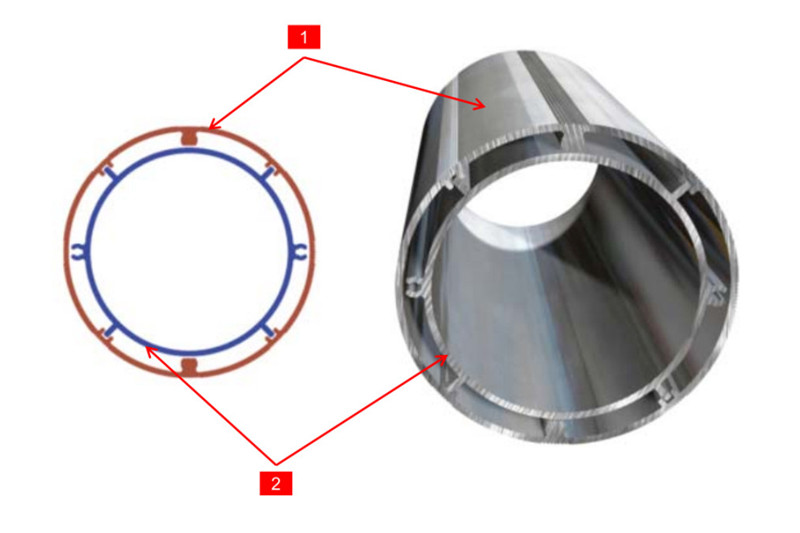

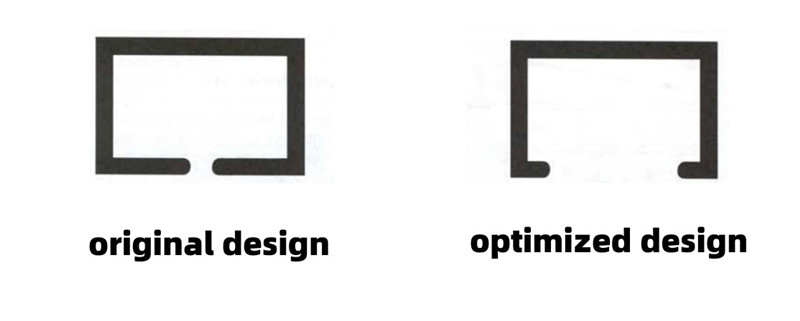

3.Icandelo elinomngxuma elinomngxuma omnye elilungiselelwe ukuba libe licandelo elinomngxuma omnye

Ngokulungisa icandelo elinomqolo elinomngxuma omnye, ukwakhiwa kwe-mold kungenziwa lula kwaye iindleko zingagcinwa.

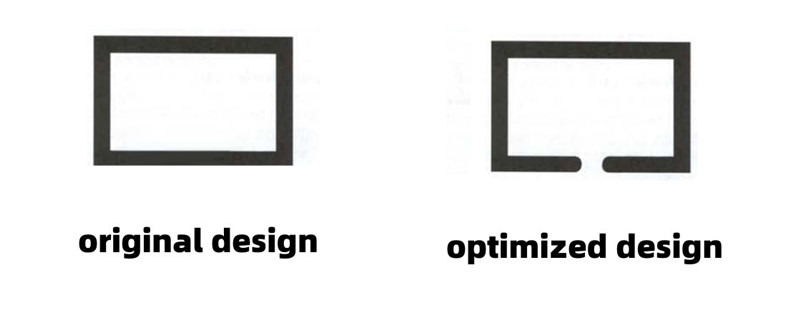

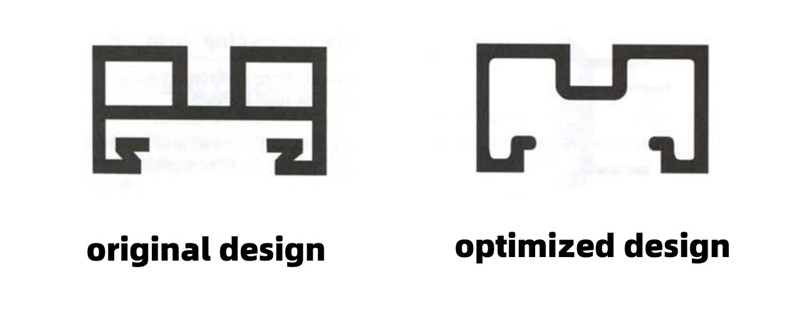

4.Icandelo eliHollow elilungiselelwe ukuba libe licandelo elingenamgongxo

Ngokulungisa icandelo elingenamngxuma ukuya kwi-semi-hollow, i-mold structure ingenziwa lula kwaye iindleko zingagcinwa.

5.Icandelo elingenamgongxo elilungiselelwe ukuba libe licandelo eliqinileyo

Ngokulungisa icandelo elingenamngxuma ukuya kwicandelo eliqinileyo, isakhiwo sokubumba sinokwenziwa lula kwaye iindleko zinokugcinwa.

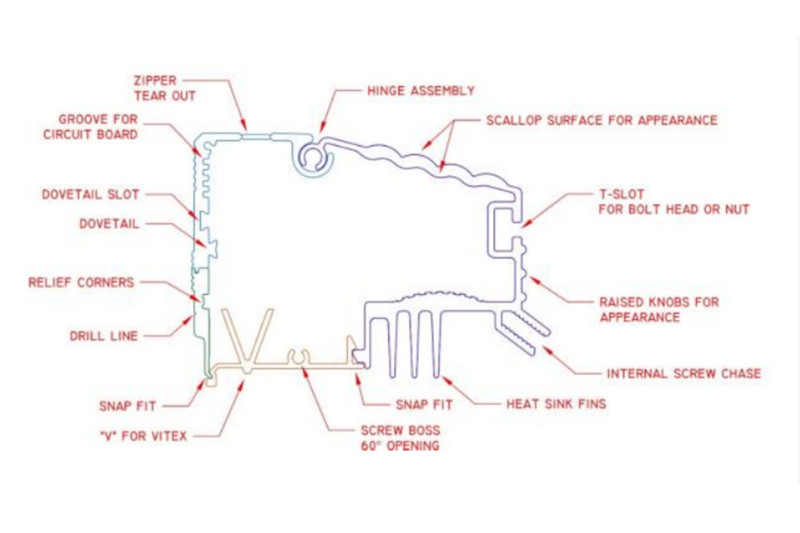

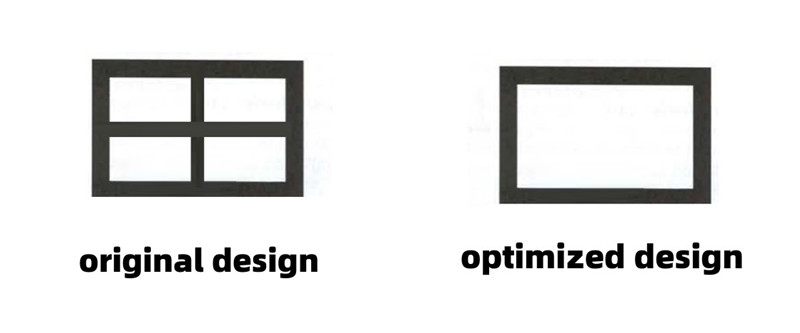

6.Kuphephe icandelo elineentunjana

Amacandelo e-Porous anokulungiswa ngokuyila ukunciphisa iindleko zokubumba kunye nobunzima bokucubungula kunye nemveliso.

Ihlelwe nguMay Jiang esuka kwiMAT Aluminium

NgoJanuwari 16, 2023

Ixesha lokuposa: Feb-18-2023