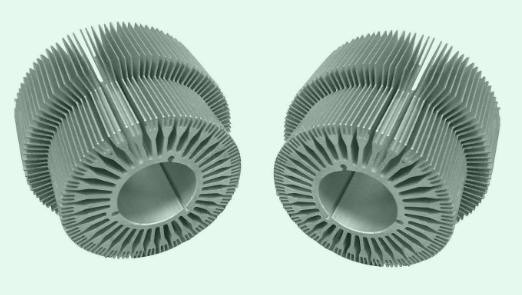

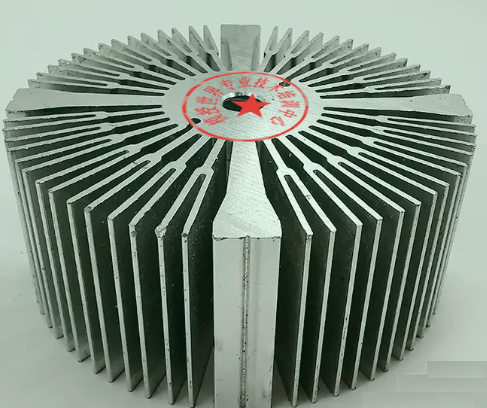

Ngenxa yokuba ii-alloys ze-aluminiyam zikhaphukhaphu, zintle, zinokumelana nokugqwala okuhle, kwaye zine-thermal conductivity egqwesileyo kunye nokusebenza kokusebenza, zisetyenziswa ngokubanzi njengamacandelo okuphelisa ubushushu kwishishini le-IT, i-electronics kunye nemizi-mveliso yeemoto, ngakumbi kushishino lwe-LED olusakhulayo. Ezi zixhobo zokuchitha ubushushu be-aluminium zinemisebenzi emihle yokuchitha ubushushu. Kwimveliso, isitshixo kwimveliso esebenzayo ye-extrusion yezi profayili ze-radiator yi-mold. Ngenxa yokuba ezi profayili ngokubanzi zineempawu amazinyo ezinkulu kunye ashinyeneyo ukuchithwa ubushushu kunye neityhubhu ukunqunyanyiswa elide, isakhiwo yemveli tyaba die, ulwahlulo isakhiwo kufa kunye nesiqingatha-hollow iprofayile die isakhiwo ayikwazi kakuhle ukuhlangabezana neemfuno amandla ngundo kunye nokubumba extrusion.

Okwangoku, amashishini athembele ngakumbi kumgangatho wentsimbi yokubumba. Ukuze kuphuculwe amandla okubumba, abanqikazi ukusebenzisa intsimbi ebiza kakhulu evela kumazwe angaphandle. Iindleko zokungunda ziphezulu kakhulu, kwaye ubomi obuqhelekileyo bobunjwa bungaphantsi kwe-3t, okubangela ukuba ixabiso lemarike yeradiyetha liphezulu kakhulu, lithintele ngokunzulu ukukhuthazwa kunye nokuthandwa kwezibane ze-LED. Ke ngoko, i-extrusion iyafa ngenxa yeeprofayili zeradiyetha ezimilise ngojongilanga ziye zatsala umdla omkhulu kubasebenzi bobunjineli kunye nabasebenzi bobuchwephesha kushishino.

Eli nqaku lazisa iitekhnoloji ezahlukeneyo zeradiyetha kajongilanga iprofayili extrusion kufa efunyenwe ngeminyaka yophando olunzima kunye novavanyo oluphindaphindiweyo lwemveliso ngemizekelo yemveliso eyiyo, ukuze kubhekiswa kuyo ngabalingane.

1. Uhlalutyo lweempawu zesakhiwo samacandelo eprofayili ye-aluminium

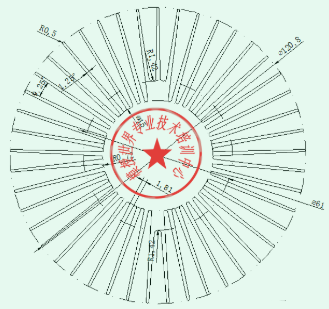

Umzobo 1 ubonisa i-cross-section ye-radiator ye-aluminium ye-radiator ye-sunflower eqhelekileyo. Ummandla onqamlezileyo weprofayile yi-7773.5mm², unamazinyo angama-40 okuphelisa ubushushu. Ubukhulu bokuxhoma ubungakanani bokuvula obukhiwe phakathi kwamazinyo yi-4.46 mm. Emva kokubala, umlinganiselo wolwimi phakathi kwamazinyo yi-15.7. Kwangaxeshanye, kukho indawo enkulu eqinileyo embindini weprofayile, enendawo eyi-3846.5mm².

Ukujonga kwiimpawu zemilo yeprofayili, isithuba phakathi kwamazinyo sinokuthathwa njengeeprofayili ze-semi-hollow, kwaye iprofayili ye-radiator yenziwe ngeeprofayili ezininzi ezingenanto. Ngoko ke, xa uyila isakhiwo sokubumba, isitshixo kukuqwalasela indlela yokuqinisekisa amandla obumba. Nangona iiprofayili ze-semi-hollow, i-shishini liphuhlise iintlobo zezakhiwo zokubumba ezivuthiweyo, ezifana "ne-mold splitter mold", "i-mold cut splitter mold", "i-suspension bridge splitter mold", njl. Uyilo lwemveli luqwalasela kuphela izinto, kodwa ekubunjweni kwe-extrusion, impembelelo enkulu kumandla yi-extrusion force ngexesha lenkqubo ye-extrusion, kunye nenkqubo yokwenza isinyithi iyona nto iphambili eyenza amandla e-extrusion.

Ngenxa yommandla omkhulu oqinileyo weprofayili yeradiyetha yelanga, kulula kakhulu ukubangela ukuba isantya sokuhamba ngokubanzi kule ndawo sikhawuleze kakhulu ngexesha lenkqubo yokukhutshwa, kwaye uxinzelelo olongezelelweyo lwe-tensile luya kuveliswa kwintloko yombhobho wokumisa we-intertooth, okukhokelela ekuqhekekeni kwetyhubhu yokumiswa kwe-intertooth. Ngoko ke, ekuyilweni kwesakhiwo sokubumba, kufuneka sigxininise ukulungiswa kwesantya sokuhamba kwetsimbi kunye nesantya sokuhamba ukufezekisa injongo yokunciphisa uxinzelelo lwe-extrusion kunye nokuphucula imeko yoxinzelelo lombhobho omisiwe phakathi kwamazinyo, ukwenzela ukuba kuphuculwe amandla obumba.

2. Ukukhethwa kwesakhiwo sokubumba kunye nomthamo we-extrusion press

2.1 Ifomu yesakhiwo sokungunda

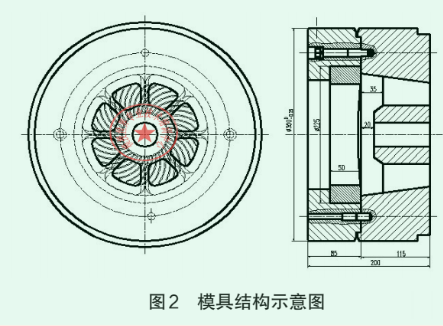

Kwiprofayili ye-radiator ye-sunflower eboniswe kwi-Figure 1, nangona ingenayo inxalenye engenanto, kufuneka ithathe i-mold mold structure njengoko kuboniswe kwi-Figure 2. Ihluke kwi-mold ye-shunt ye-mold yendabuko, igumbi lesikhululo se-metal soldering lifakwe kwi-mold ephezulu, kwaye isakhiwo sokufaka sisetyenziswe kwi-mold ephantsi. Injongo kukunciphisa iindleko zokungunda kunye nokunciphisa umjikelo wokuvelisa ubumba. Zombini ukungunda okuphezulu kunye neseti zokungunda ezisezantsi zendalo yonke kwaye zingaphinda zisetyenziswe. Okubaluleke ngakumbi, iibhloko zomngxuma wokufa zinokucutshungulwa ngokuzimeleyo, ezinokuthi ziqinisekise ngakumbi ukuchaneka kwebhanti yomsebenzi womngxuma wokufa. Umngxuma wangaphakathi wesikhunta esisezantsi senziwe njengesinyathelo. Inxalenye ephezulu kunye nebloko yomngxuma wokungunda ithatha indawo yokucima, kwaye ixabiso lesithuba kumacala omabini yi-0.06 ~ 0.1m; inxalenye engezantsi ithatha ukulungelelaniswa kokuphazamiseka, kunye nemali yokuphazamiseka kumacala omabini yi-0.02 ~ 0.04m, enceda ukuqinisekisa ukuba i-coaxiality kwaye iququzelele ukudibanisa, ukwenza i-inlay ifake i-compact ngakumbi, kwaye kwangaxeshanye, inokuphepha ukuguqulwa kwesikhunta esibangelwa kukuphazamiseka kokufakelwa kwe-thermal.

2.2 Ukukhethwa komthamo we-extruder

Ukukhethwa komthamo we-extruder, kwelinye icala, ukumisela i-diameter yangaphakathi efanelekileyo ye-extrusion barrel kunye noxinzelelo oluphezulu oluthile lwe-extruder kwicandelo lombhobho we-extrusion ukuhlangabezana noxinzelelo ngexesha lokwenziwa kwesinyithi. Ngakolunye uhlangothi, kukumisela umlinganiselo ofanelekileyo we-extrusion kwaye ukhethe ubungakanani obufanelekileyo bokubumba ngokusekwe kwindleko. Kwiprofayili ye-radiator ye-sunflower ye-aluminium, umlinganiselo we-extrusion awukwazi ukuba mkhulu kakhulu. Isizathu esona sizathu kukuba amandla e-extrusion alingana nomlinganiselo we-extrusion. Okukhona umlinganiselo omkhulu we-extrusion, kokukhona amandla e-extrusion. Oku kunokonakalisa kakhulu ukungunda kweprofayili yeradiyetha kajongilanga.

Amava abonisa ukuba i-extrusion ratio yeeprofayili ze-aluminium kwi-radiator ye-sunflower ingaphantsi kwama-25. Kwiprofayili eboniswe kuMzobo 1, i-20.0 MN extruder kunye ne-extrusion barrel ububanzi be-208 mm yakhethwa. Emva kokubala, ubuninzi boxinzelelo oluthile lwe-extruder yi-589MPa, ixabiso elifanelekileyo ngakumbi. Ukuba uxinzelelo oluthile luphezulu kakhulu, uxinzelelo kwi-mold luya kuba lukhulu, oluyonakalisa ubomi bobumba; ukuba uxinzelelo oluthile luphantsi kakhulu, alukwazi ukuhlangabezana neemfuno zokwenza i-extrusion. Amava abonisa ukuba uxinzelelo oluthile kuluhlu lwe-550 ~ 750 MPa lunokuhlangabezana ngcono neemfuno zenkqubo ezahlukeneyo. Emva kokubala, i-extrusion coefficient yi-4.37. Ubume besayizi yokungunda bukhethwe njenge-350 mmx200 mm (ngaphandle kwedayamitha x izidanga).

3. Ukumiselwa kweeparamitha zesakhiwo sokungunda

3.1 Iiparamitha zesakhiwo somngundo ophezulu

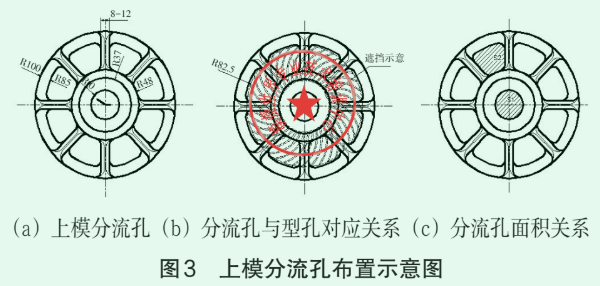

(1) Inani kunye nolungiselelo lwemingxuma yokuphambukisa. Kwiprofayili yeradiyetha kajongilanga i-shunt mold, ngakumbi inani lemingxuma ye-shunt, ingcono. Kwiiprofayili ezinemilo yesetyhula efanayo, i-3 ukuya kwi-4 imingxuma yendabuko ye-shunt ikhethwa ngokubanzi. Isiphumo kukuba ububanzi bebhulorho ye-shunt bukhulu. Ngokuqhelekileyo, xa inkulu kune-20mm, inani le-welds lingaphantsi. Nangona kunjalo, xa ukhetha ibhanti elisebenzayo lomngxuma wokufa, ibhanti lokusebenza lomngxuma wokufa phantsi kwebhulorho ye-shunt kufuneka ibe mfutshane. Ngaphantsi kwemeko yokuba akukho ndlela yokubala echanekileyo yokukhethwa kwebhanti esebenzayo, kuya kubangela ngokwemvelo ukuba umngxuma wokufa phantsi kwebhulorho kunye nezinye iindawo zingaphumeleli ngokuthe ngqo isantya sokuhamba ngexesha lokukhupha ngenxa yokwahlukana kwebhanti yokusebenza, Lo mahluko kwisantya sokuhamba uya kuvelisa uxinzelelo olongezelelweyo kwi-cantilever kwaye kubangele ukuphambuka kwamazinyo okutshatyalaliswa kobushushu. Ke ngoko, kwiradiyetha kajongilanga extrusion kufa kunye nenani elishinyeneyo lamazinyo, kubaluleke kakhulu ukuqinisekisa ukuba izinga lokuhamba kwezinyo ngalinye lihambelana. Njengoko inani lemingxuma ye-shunt likhula, inani leebhuloho ze-shunt liya kwanda ngokufanelekileyo, kwaye izinga lokuhamba kunye nokuhanjiswa kwentsimbi kuya kuba ngakumbi. Oku kungenxa yokuba njengoko inani leebhuloho ze-shunt landa, ububanzi beebhuloho ze-shunt bunokunciphisa ngokufanelekileyo.

Idatha esebenzayo ibonisa ukuba inani lemingxuma ye-shunt ngokubanzi yi-6 okanye i-8, okanye nangaphezulu. Ngokuqinisekileyo, kwezinye iiprofayili ezinkulu zokuchitha ubushushu bejongilanga, ukungunda okuphezulu kunokucwangcisa imingxuma ye-shunt ngokomgaqo wobubanzi bebhulorho ye-shunt ≤ 14mm. Umahluko kukuba i-plate ye-splitter yangaphambili kufuneka yongezwe ukusabalalisa kwangaphambili kunye nokulungelelanisa ukuhamba kwesinyithi. Inani kunye nokucwangciswa kwemingxuma ye-diverter kwi-plate ye-diverter yangaphambili inokuqhutywa ngendlela yendabuko.

Ukongezelela, xa ulungiselela imingxuma ye-shunt, kufuneka kuqwalaselwe ukusetyenziswa kwesikhunta esiphezulu ukukhusela ngokufanelekileyo intloko ye-cantilever yezinyo lokutshatyalaliswa kobushushu ukukhusela isinyithi ekubetheni ngokuthe ngqo intloko yombhobho we-cantilever kwaye ngaloo ndlela kuphuculwe imeko yoxinzelelo lwe-tube cantilever. Inxalenye evaliweyo yentloko ye-cantilever phakathi kwamazinyo ingaba yi-1/5 ~ 1/4 yobude betyhubhu ye-cantilever. Uyilo lwemingxuma ye-shunt luboniswe kuMfanekiso 3

(2) Ubudlelwane bendawo yomngxuma we-shunt. Ngenxa yokuba ubukhulu bodonga lwengcambu yezinyo elitshisayo lincinci kwaye ukuphakama kukude neziko, kwaye indawo ebonakalayo ihluke kakhulu kwiziko, iyona nto inzima kakhulu ukwenza isinyithi. Ngoko ke, inqaku eliphambili kuyilo lokungunda kweprofayili yeradiyetha kajongilanga kukwenza izinga lokuhamba kwenxalenye eqinileyo ephakathi ngokukhawuleza kangangoko ukuqinisekisa ukuba isinyithi sizalise kuqala ingcambu yezinyo. Ukuze ufezekise umphumo onjalo, ngakwesinye icala, kukukhethwa kwebhanti yokusebenza, kwaye ngokubaluleke ngakumbi, ukuzimisela kwendawo ye-diverter hole, ngokukodwa indawo yecandelo eliphakathi elihambelana nomngxuma wokuphambukisa. Uvavanyo kunye nemilinganiselo yobungqina ibonisa ukuba isiphumo esihle siphunyezwa xa indawo ye-diverter ephakathi yomngxuma i-S1 kunye nommandla we-diverter yangaphandle yomngxuma we-S2 iyanelisa ubudlelwane obulandelayo: S1 = (0.52 ~ 0.72) S2

Ukongeza, umjelo osebenzayo wesinyithi wentsimbi ephakathi komngxuma oqhekezayo kufuneka ube ngama-20 ~ 25mm ubude kunomjelo osebenzayo wesinyithi womngxuma wangaphandle oqhekezayo. Obu bude bukwathathela ingqalelo umda kunye nokwenzeka kokulungiswa komngundo.

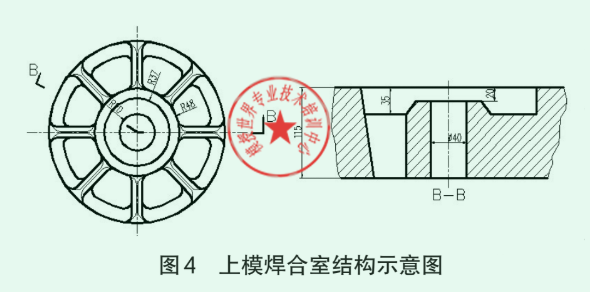

(3) Ubunzulu begumbi le-welding. Iradiyetha kajongilanga iprofayili extrusion die yahlukile kwi-shunt die yemveli. Igumbi layo lonke le-welding kufuneka libekwe kwindawo ephezulu. Oku kukuqinisekisa ukuchaneka kokulungiswa kwebhloko yomngxuma wokufa okuphantsi, ngokukodwa ukuchaneka kwebhanti yokusebenza. Xa kuthelekiswa nokungunda kwe-shunt yemveli, ubunzulu begumbi le-welding ye-sunflower radiator profile shunt mold kufuneka bandiswe. Ubukhulu bomthamo womatshini we-extrusion, ukwanda okukhulu kobunzulu begumbi le-welding, eli-15 ~ 25mm. Ngokomzekelo, ukuba kusetyenziswe umatshini we-20 MN we-extrusion, ubunzulu begumbi le-welding ye-shunt yendabuko yokufa yi-20 ~ 22mm, ngelixa ubunzulu begumbi le-welding ye-shunt die yeprofayili ye-radiator kajongilanga kufuneka ibe yi-35 ~ 40 mm. Inzuzo yale nto kukuba isinyithi sihlanganiswe ngokupheleleyo kwaye uxinzelelo kumbhobho omisiwe luyancipha kakhulu. Ubume begumbi le-welding ephezulu liboniswe kuMfanekiso 4.

3.2 Uyilo lokufakela umngxuma wokufa

Uyilo lwebloko lomngxuma wokufa ikakhulu lubandakanya ubungakanani bomngxuma wokufa, ibhanti elisebenzayo, ububanzi bangaphandle kunye nobukhulu bebhloko yesibuko, njl.

(1) Ukumiselwa kobungakanani bomngxuma wokufa. Ubungakanani bomngxuma wokufa bunokumiselwa ngendlela yemveli, ikakhulu kuqwalaselwe ukukala kwe-alloy processing thermal.

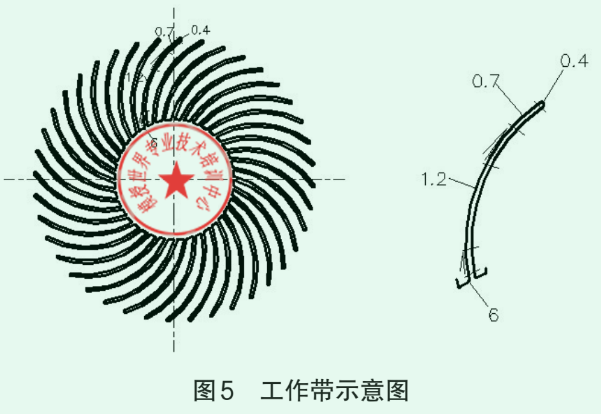

(2) Ukukhethwa kwebhanti yomsebenzi. Umgaqo wokukhethwa kwebhanti kukuqala ukuqinisekisa ukuba ukunikezelwa kwazo zonke isinyithi phantsi kweengcambu zezinyo kwanele, ukwenzela ukuba izinga lokuhamba ngaphantsi kweengcambu zamazinyo likhawuleza kunezinye iindawo. Ngoko ke, ibhande elisebenzayo phantsi kweengcambu zezinyo kufuneka libe lifutshane, ngexabiso le-0.3 ~ 0.6mm, kwaye ibhande elisebenzayo kwiindawo ezikufutshane kufuneka linyuswe ngo-0.3mm. Umgaqo kukunyuka ngo-0.4 ~ 0.5 rhoqo nge-10 ~ 15mm ukuya kumbindi; okwesibini, ibhanti yokusebenza kwindawo enkulu eqinileyo yeziko akufanele idlule i-7mm. Ngaphandle koko, ukuba ubude bobude bebhanti yokusebenza bukhulu kakhulu, iimpazamo ezinkulu ziya kwenzeka ekuqhutyweni kwee-electrode zethusi kunye nokulungiswa kwe-EDM yebhanti yokusebenza. Le mpazamo inokubangela ukuba ukuphambuka kwamazinyo kuphuke ngexesha lenkqubo ye-extrusion. Ibhanti yomsebenzi iboniswe kwi-Figure 5.

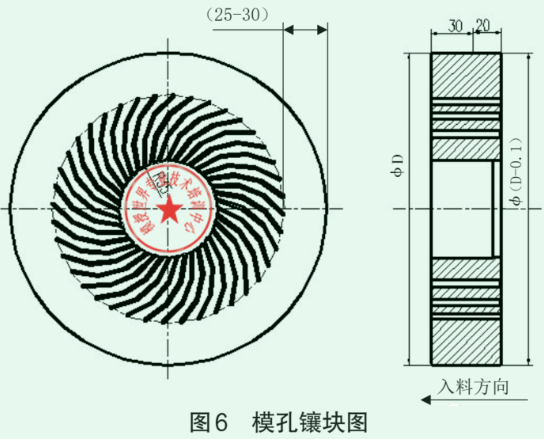

(3) Idayamitha yangaphandle kunye nobungqingqwa bokufakela. Kwimibumbo ye-shunt yemveli, ubukhulu bokufakwa komngxuma wokufa bubunzima bomngundo osezantsi. Nangona kunjalo, kubumba lweradiyetha kajongilanga, ukuba ubukhulu obusebenzayo bomngxuma wokufa bukhulu kakhulu, iprofayili iya kungqubana ngokulula nokungunda ngexesha lokukhupha kunye nokukhupha, okukhokelela kumazinyo angalinganiyo, imikrwelo okanye ukuxinana kwamazinyo. Oku kuya kubangela ukuba amazinyo aphuke.

Ukongezelela, ukuba ubukhulu bomngxuma wokufa bude kakhulu, ngakwesinye icala, ixesha lokucubungula lide ngexesha lenkqubo ye-EDM, kwaye ngakolunye uhlangothi, kulula ukubangela ukuphambuka kokubola kombane, kwaye kulula ukubangela ukuphambuka kwezinyo ngexesha lokukhupha. Ngokuqinisekileyo, ukuba ubukhulu bomngxuma wokufa buncinci kakhulu, amandla amazinyo akanakuqinisekiswa. Ngoko ke, ukuthatha ezi zinto zimbini ziqwalaselwe, amava abonisa ukuba iqondo lokufakela umngxuma wokufa komngundo osezantsi ngokubanzi lingama-40 ukuya kuma-50; kunye nobubanzi obungaphandle bomngxuma wokufa kufuneka bube ngama-25 ukuya kuma-30 mm ukusuka kowona mgca mkhulu womngxunya wokufa ukuya kwisangqa esingaphandle sofakelo.

Kwiprofayili eboniswe kuMfanekiso 1, ububanzi bangaphandle kunye nobukhulu bebloko yomngxuma wokufa yi-225mm kunye ne-50mm ngokulandelanayo. Ukufakwa komngxuma wokufa kuboniswe kuMfanekiso 6. D kumfanekiso ubukhulu becala kunye nobukhulu obuqhelekileyo bungama-225mm. Ukuphambuka komda wemilinganiselo yayo yangaphandle ihambelana nomngxuma wangaphakathi we-mold ephantsi ukuqinisekisa ukuba i-gap e-unilateral iphakathi koluhlu lwe-0.01 ~ 0.02mm. Ibloko yomngxuma wokufa iboniswe kuMfanekiso 6. Ubungakanani obuqhelekileyo bomngxuma ongaphakathi webloko yomngxuma wokufa obekwe kumngundo ongezantsi yi-225mm. Ngokusekelwe kumlinganiselo wangempela olinganisiweyo, ibhloko yomngxuma wokufa ihambelana nomgaqo we-0.01 ~ 0.02mm kwicala ngalinye. I-diameter yangaphandle yebloko yomngxuma wokufa inokufumaneka njenge-D, kodwa ukwenzela ukuba kube lula ukufakela, i-diameter yangaphandle yebhloko yesibuko se-die hole ingancitshiswa ngokufanelekileyo phakathi koluhlu lwe-0.1m ekupheleni kokutya, njengoko kubonisiwe kumfanekiso.

4. Ubuchwephesha obuphambili bokwenziwa kokungunda

Ukwenziwa kwemold yeradiyetha kajongilanga akuhlukanga kangako kuleyo yeprofayile ye-aluminium eqhelekileyo. Umahluko ocacileyo ubonakaliswa ngokuyintloko ekuqhutyweni kombane.

(1) Ngokumalunga nokusika ucingo, kuyimfuneko ukukhusela i-deformation ye-electrode yobhedu. Ngenxa yokuba i-electrode yobhedu esetyenziselwa i-EDM inzima, amazinyo amancinci kakhulu, i-electrode ngokwayo ithambile, inobunzima obunzima, kwaye ubushushu obuphezulu bendawo obuveliswa ngokusika ucingo kubangela ukuba i-electrode ikhubazeke ngokulula ngexesha lenkqubo yokusika ucingo. Xa usebenzisa i-electrode yethusi ekhubazekileyo ukucubungula amabhanti omsebenzi kunye neemela ezingenanto, amazinyo ahlambulukileyo aya kwenzeka, angenza lula ukuba ukubunjwa kukhutshwe ngexesha lokucubungula. Ngoko ke, kuyimfuneko ukukhusela ukuguqulwa kwee-electrode zethusi ngexesha lenkqubo yokwenziwa kwe-intanethi. Amanyathelo okukhusela aphambili: ngaphambi kokusika ucingo, phakamisa ibhloko yobhedu ngebhedi; sebenzisa isalathisi sokucofa ukulungisa ukuthe nkqo ekuqaleni; xa usika ucingo, qala ukusuka kwindawo yezinyo kuqala, kwaye ekugqibeleni usike inxalenye ngodonga olungqingqwa; Njalo kanye ngexesha elithile, sebenzisa i-scrap wire yesilivere ukuzalisa iindawo ezisikiweyo; emva kokuba ucingo lwenziwe, sebenzisa umatshini wocingo ukunqumla icandelo elifutshane malunga ne-4 mm kunye nobude be-electrode yobhedu esikiweyo.

(2) Umatshini wokukhupha umbane ngokucacileyo uhluke kwiimbumba eziqhelekileyo. I-EDM ibaluleke kakhulu ekusetyenzweni kweprofayili ye-radiator ye-sunflower. Nangona uyilo lugqibelele, i-defect encinci kwi-EDM iya kubangela ukuba i-mold yonke ikhutshwe. Ukukhutshwa kombane komatshini akuxhomekeke kwisixhobo njengokusika ucingo. Kuxhomekeke kakhulu kwizakhono zokusebenza kunye nobuchule bomqhubi. Ukukhutshwa kombane ngomatshini ikakhulu kunikela ingqalelo kwezi ngongoma zintlanu zilandelayo:

①Umbane wokukhupha umatshini wangoku. I-7~10 yangoku ingasetyenziselwa umatshini wokuqala we-EDM ukunciphisa ixesha lokucubungula; 5 ~ 7 Umsinga ungasetyenziselwa ukugqiba oomatshini. Injongo yokusebenzisa umsinga omncinci kukufumana umgangatho olungileyo;

② Qinisekisa ukunyameka kobuso besiphelo sokubumba kunye nokuma kwe-electrode yobhedu. I-flatness embi ye-mold end face okanye ukunganyaniseki okwaneleyo kwe-electrode yobhedu kwenza kube nzima ukuqinisekisa ukuba ubude bebhanti yomsebenzi emva kokucutshungulwa kwe-EDM kuhambelana nobude bebhanti eyenzelwe umsebenzi. Kulula ukuba inkqubo ye-EDM ingaphumeleli okanye ingene kwibhanti yomsebenzi onamazinyo. Ngoko ke, ngaphambi kokucutshungulwa, i-grinder kufuneka isetyenziswe ukubetha iziphelo zombini zesikhunta ukuhlangabezana neemfuno zokuchaneka, kwaye isalathisi sokudayela kufuneka sisetyenziswe ukulungisa i-verticality ye-electrode yethusi;

③ Qinisekisa ukuba umsantsa phakathi kweemela ezingenanto ulungelelene. Ngexesha lokwenziwa komatshini wokuqala, khangela ukuba isixhobo esingenanto sichithwa rhoqo nge-0.2 mm nganye kwi-3 ukuya kwi-4 mm yokucubungula. Ukuba i-offset inkulu, kuya kuba nzima ukuyilungisa ngohlengahlengiso olulandelayo;

④Susa intsalela eyenziwe ngexesha lenkqubo ye-EDM ngexesha elifanelekileyo. I-Spark discharge corrosion iya kuvelisa inani elikhulu lentsalela, ekufuneka ihlanjululwe ngexesha, ngaphandle koko ubude bebhanti yokusebenza buya kuba buhluke ngenxa yokuphakama okuhlukeneyo kwentsalela;

⑤Ukungunda kufuneka kukhutshwe iimagnethi phambi kwe-EDM.

5. Ukuthelekiswa kweziphumo ze-extrusion

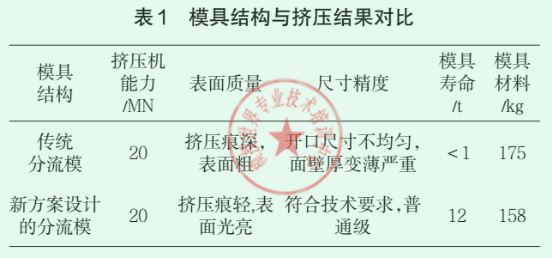

Iprofayili eboniswe kwi-Figure 1 yavavanywa ngokusebenzisa i-mold yendabuko yokwahlula kunye neskimu soyilo esitsha esicetywayo kweli nqaku. Ukuthelekiswa kweziphumo kuboniswe kwiThebhile 1.

Inokubonwa kwiziphumo zokuthelekisa ukuba isakhiwo sokubumba sinempembelelo enkulu kubomi bokubumba. Umngundo owenziwe kusetyenziswa inkqubo entsha uneenzuzo ezicacileyo kwaye uphucula kakhulu ubomi bokubumba.

6. Isiphelo

Iradiyetha kajongilanga iprofayili extrusion ngundo luhlobo lokungunda kunzima kakhulu ukuyila kunye nokwenza, kunye noyilo kunye nokuveliswa kwayo kunzima. Ke ngoko, ukuqinisekisa izinga lempumelelo ye-extrusion kunye nobomi benkonzo yokubumba, la manqaku alandelayo kufuneka afezekiswe:

(1) Ifom yesakhiwo sokubumba kufuneka ikhethwe ngokufanelekileyo. Ukwakhiwa kwesikhunta kufuneka kube luncedo ekunciphiseni amandla e-extrusion ukunciphisa uxinzelelo kwi-mold cantilever eyenziwe ngamazinyo okutshatyalaliswa kobushushu, ngaloo ndlela kuphuculwe amandla okubumba. Isitshixo kukumisela ngokufanelekileyo inani kunye nokulungelelaniswa kwemingxuma ye-shunt kunye nommandla wemingxuma ye-shunt kunye nezinye iiparitha: okokuqala, ububanzi bebhuloho ye-shunt eyenziwe phakathi kwemingxuma ye-shunt akufanele idlule i-16mm; Okwesibini, indawo yomngxuma oqhekezayo kufuneka imiselwe ukwenzela ukuba umlinganiselo wokwahlula ufikelele ngaphezu kwe-30% ye-extrusion ratio kangangoko kunokwenzeka ngelixa uqinisekisa amandla obumba.

(2) Ngokufanelekileyo khetha ibhanti lomsebenzi kwaye wamkele amanyathelo afanelekileyo ngexesha lokucoca umbane, kubandakanywa iteknoloji yokucubungula i-electrode yobhedu kunye nemilinganiselo yombane yombane wokucoca umbane. Inqaku lokuqala eliphambili kukuba i-electrode yethusi kufuneka ibe phezu komhlaba ngaphambi kokusika ucingo, kwaye indlela yokufaka kufuneka isetyenziswe ngexesha lokusika ucingo ukuze kuqinisekiswe. I-electrodes ayikhululekanga okanye ikhubazekile.

(3) Ngethuba lenkqubo yokucoca umbane, i-electrode kufuneka ihambelane ngokuchanekileyo ukuphepha ukuphambuka kwamazinyo. Ngokuqinisekileyo, ngesiseko soyilo olufanelekileyo kunye nokuveliswa, ukusetyenziswa kwensimbi yomgangatho obushushu obushushu kunye nenkqubo yokucoca ubushushu be-vacuum yobushushu obuthathu okanye ngaphezulu kunokwandisa amandla okubumba kunye nokufezekisa iziphumo ezingcono. Ukusuka kuyilo, ukuveliswa ukuya kwimveliso ye-extrusion, kuphela ukuba ikhonkco ngalinye lichanekile sinokuqinisekisa ukuba iprofayili yeradiyetha kajongilanga ikhutshiwe.

Ixesha lokuposa: Aug-01-2024