Intshayelelo

Ngophuhliso loshishino lweemoto, imakethi ye-aluminiyam yempembelelo ye-alloy beam nayo ikhula ngokukhawuleza, nangona incinci kubungakanani bayo bonke. Ngokutsho koqikelelo yi-Automotive Lightweight Technology Innovation Alliance ye-Aluminiyam yaseTshayina impembelelo ye-alloy impembelelo kwimarike ye-alloy, ngo-2025, imfuno yemarike iqikelelwa ukuba ibe malunga ne-140,000 yeetoni, kunye nobukhulu bemarike kulindeleke ukuba bufikelele kwi-4.8 yezigidigidi ze-RMB. Ngo-2030, imfuno yemarike kulindeleke ukuba ibe malunga ne-220,000 yeetoni, kunye nobukhulu obuqikelelwayo be-7.7 yebhiliyoni ye-RMB, kunye nezinga lokukhula ngonyaka elimalunga ne-13%. Umkhwa wokuphuhliswa kokukhanya kunye nokukhula okukhawulezayo kweemodeli zemoto eziphakathi ukuya phezulu zibalulekile izinto zokuqhuba ukuphuhliswa kwe-aluminium impembelelo ye-alloy beams e-China. Amathuba emarike eebhokisi zokungqubana kwe-automotive beam beam ayathembisa.

Njengoko iindleko zisehla kunye nokuhambela phambili kwetekhnoloji, imiqadi yempembelelo yealluminiyam engaphambili kunye neebhokisi zokuphahlazeka ngokuthe ngcembe ziya zisasazeka. Okwangoku, zisetyenziswe kwimodeli yemoto ephakathi ukuya phezulu njenge-Audi A3, i-Audi A4L, i-BMW 3 series, i-BMW X1, i-Mercedes-Benz C260, i-Honda CR-V, i-Toyota RAV4, i-Buick Regal, kunye ne-Buick LaCrosse.

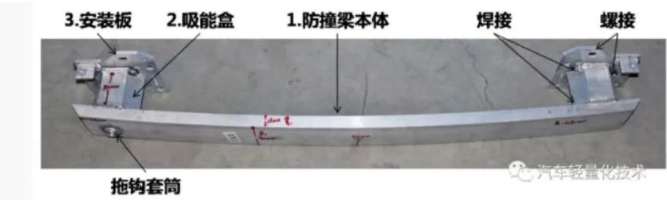

Imiqadi yealuminiyam yempembelelo yealloyi iqulunqwe ikakhulu yimiqadi enqamlezileyo, iibhokisi zokuwa, iiplates ezinyuswayo, kunye nemikhono yokutsala ihuku, njengoko kubonisiwe kuMfanekiso 1.

Umzobo 1: I-Aluminium Alloy Impact Beam Assembly

Ibhokisi yokuphahlazeka yibhokisi yentsimbi ebekwe phakathi komqadi wempembelelo kunye nemiqadi emibini yobude besithuthi, ngokuyimfuneko isebenza njengesitya sokufunxa amandla. La mandla abhekisa kumandla empembelelo. Xa isithuthi sifumana ukungqubana, umqadi wempembelelo uneqondo elithile lokukwazi ukufunxa amandla. Nangona kunjalo, ukuba amandla adlula umthamo we-beam yempembelelo, iya kudlulisela amandla kwibhokisi yokuphahlazeka. Ibhokisi yokuwa ifunxa onke amandla empembelelo kwaye iyaziguqula, iqinisekisa ukuba imiqadi yelongitudinal ihlala ingonakaliswa.

1 Iimfuno zeMveliso

1.1 Imilinganiselo mayihambelane neemfuno zokunyamezela umzobo, njengoko kubonisiwe kuMfanekiso 2.

1.3 IiMfuno zokuSebenza koomatshini:

Amandla okuqina: ≥215 MPa

Amandla eSivuno: ≥205 MPa

Elongation A50: ≥10%

1.4 Umsebenzi wokuNtyumza iBhokisi yokuNwabeka:

Ecaleni kwe-X-axis yesithuthi, usebenzisa indawo yokungqubuzana enkulu kunecandelo le-cross-section yemveliso, ukulayisha ngesantya se-100 mm / min kude kube ngokutyumzayo, kunye nenani loxinzelelo lwe-70%. Ubude bokuqala beprofayili yi-300 mm. Ekudibaneni kweembambo zokuqinisa kunye nodonga lwangaphandle, iintanda kufuneka zibe ngaphantsi kwe-15 mm ukuba zithathwe njengezamkelekileyo. Kufuneka kuqinisekiswe ukuba ukuqhekeka okuvunyelweyo akuthinteli iprofayili yokutyumza amandla okuxhamla amandla, kwaye akufanele kubekho ukuqhekeka okuphawulekayo kwezinye iindawo emva kokutyumza.

2 Indlela yoPhuhliso

Ukuhlangabezana ngaxeshanye neemfuno zokusebenza koomatshini kunye nokusebenza okutyumzayo, indlela yophuhliso yile ilandelayo:

Sebenzisa i-6063B intonga kunye ne-primary alloy composition of Si 0.38-0.41% kunye ne-Mg 0.53-0.60%.

Yenza ukucima umoya kunye nokuguga okwenziweyo ukufezekisa imeko ye-T6.

Qasha inkungu + ukucima umoya kwaye uqhube unyango lokuguga ngokugqithisileyo ukufezekisa imeko ye-T7.

3 Imveliso yePilot

3.1 IiMeko zokuKhulisa

Imveliso iqhutyelwa kwi-press ye-2000T ye-extrusion kunye ne-extrusion ratio ye-36. Izinto ezisetyenzisiweyo zi-homogenized aluminium rod 6063B. Amaqondo okushisa okufudumeza intonga ye-aluminium ngolu hlobo lulandelayo: indawo ye-IV ye-450-III indawo ye-470-II indawo ye-490-1 indawo 500. Uxinzelelo oluphambili lwe-cylinder luhamba ngokujikeleza i-bar ye-210, kunye nesigaba esizinzile se-extrusion esinoxinzelelo lwe-extrusion kufuphi ne-180 bar. Isantya se-shaft ye-extrusion yi-2.5 mm / s, kunye nesantya seprofayili ye-extrusion yi-5.3 m / min. Ubushushu kwindawo yokukhupha i-extrusion yi-500-540°C. Ukucima kwenziwa kusetyenziswa ukupholisa komoya ngamandla efeni asekhohlo kwi-100%, amandla efeni aphakathi kwi-100%, kunye namandla fan fan kwi-50%. Umyinge wokupholisa umyinge ngaphakathi kwendawo yokucima ufikelela kwi-300-350 ° C / min, kwaye ubushushu emva kokuphuma kwindawo yokucima yi-60-180 ° C. Kwinkungu + yokucima umoya, izinga lokupholisa eliphakathi kwendawo yokufudumeza lifikelela kwi-430-480 ° C / min, kwaye iqondo lokushisa emva kokuphuma kwindawo yokucima i-50-70 ° C. Iprofayile ayibonisi ukugoba okubalulekileyo.

3.2 Ukuguga

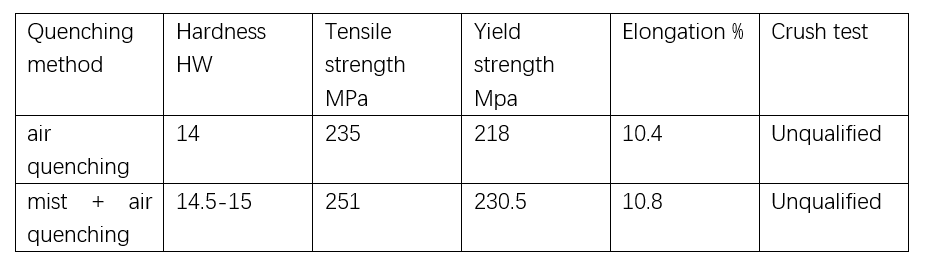

Ukulandela inkqubo yokuguga ye-T6 kwi-185 ° C kwiiyure ze-6, ubunzima bezinto eziphathekayo kunye neempawu zomatshini zimi ngolu hlobo lulandelayo:

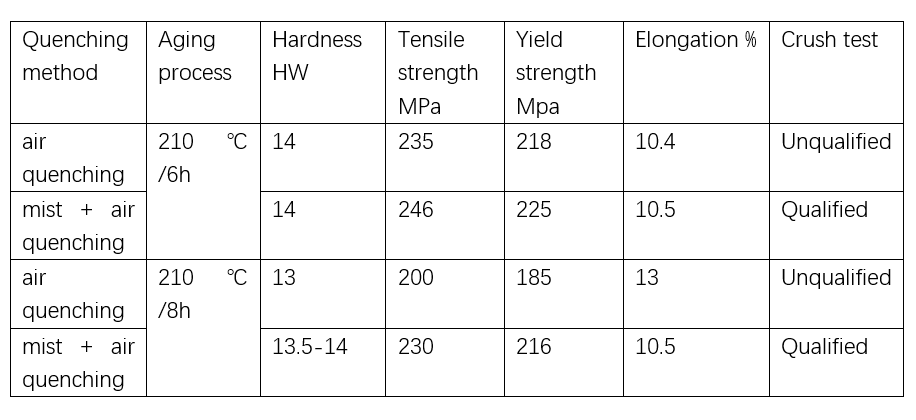

Ngokwenkqubo yokuguga ye-T7 kwi-210 ° C kwiiyure ze-6 kunye neeyure ze-8, ubunzima bezinto eziphathekayo kunye neempawu zomatshini zimi ngolu hlobo lulandelayo:

Ngokusekelwe kwidatha yovavanyo, inkungu + indlela yokucima umoya, idibene ne-210 ° C / 6h inkqubo yokuguga, ihlangabezana neemfuno zombini ukusebenza komatshini kunye novavanyo olutyumzayo. Ukuqwalasela indleko-esebenzayo, inkungu + indlela yokucima umoya kunye nenkqubo yokuguga ye-210 ° C / 6h yakhethwa kwimveliso ukuhlangabezana neemfuno zemveliso.

3.3 Uvavanyo lokuThwalaza

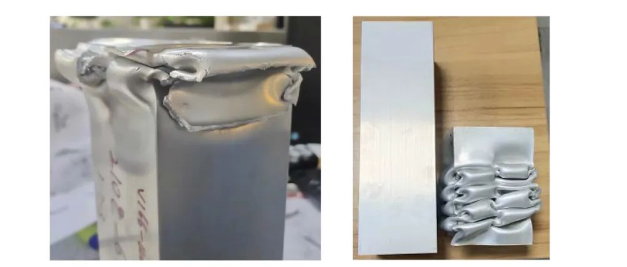

Kwiintonga zesibini nezesithathu, isiphelo sentloko sinqunyulwa ngu-1.5m, kwaye umsila unqunywe ngu-1.2m. Iisampulu ezimbini inye ithathwa ukusuka kumacandelo entloko, phakathi, kunye nomsila, kunye nobude obuyi-300mm. Iimvavanyo ezityumzayo zenziwa emva kokuguga kwi-185 ° C / 6h kunye ne-210 ° C / 6h kunye ne-8h (idatha yokusebenza komatshini njengoko kuchazwe ngasentla) kumatshini wokuvavanya izinto eziphathekayo. Iimvavanyo ziqhutyelwa kwisantya sokulayisha i-100 mm / min kunye nesixa soxinzelelo lwe-70%. Iziphumo zezi zilandelayo: ngenxa yenkungu + yokucima umoya kunye ne-210 ° C / 6h kunye ne-8h iinkqubo zokuguga, iimvavanyo zokutyumza zihlangabezana neemfuno, njengoko kuboniswe kuMzobo 3-2, ngelixa iisampuli ezicinyiweyo zomoya zibonisa ukuqhekeka kuzo zonke iinkqubo zokuguga.

Ngokusekelwe kwiziphumo zovavanyo olutyumzayo, inkungu + ukucima umoya nge-210 ° C / 6h kunye ne-8h iinkqubo zokuguga zihlangabezana neemfuno zomthengi.

4 Isiphelo

Ukulungiswa kweenkqubo zokucima kunye nokuguga kubalulekile kuphuhliso oluyimpumelelo lwemveliso kwaye lubonelela ngesisombululo esifanelekileyo senkqubo yemveliso yebhokisi yokuphahlazeka.

Ngokusebenzisa uvavanyo olubanzi, kuye kwamiselwa ukuba imeko yezinto eziphathekayo kwimveliso yebhokisi yokuphahlazeka kufuneka ibe yi-6063-T7, indlela yokucima inkungu + yokupholisa umoya, kunye nenkqubo yokuguga kwi-210 ° C / 6h iyona nto ikhethekileyo yokukhupha iintonga ze-aluminium kunye namaqondo okushisa avela kwi-480-500 ° C, i-extrusion shaft ye-8. kunye nobushushu bokukhutshwa kwe-extrusion ye-500-540 °C.

Ihlelwe nguMay Jiang esuka kwiMAT Aluminium

Ixesha lokuposa: May-07-2024