Ixesha lokubamba iiprofayili ze-aluminium ezikhutshiweyo zichongwa ikakhulu yinqanaba lesisombululo esiqinileyo sesigaba esomeleziweyo. Izinga lesisombululo esiluqilima sesigaba esomeleziweyo sinxulumene nobushushu bokucima ubushushu, ubume be-alloy, urhulumente, ubungakanani becandelo leprofayili ye-aluminium, iimeko zokufudumeza, okuphakathi kunye nenani lezinto zokulayisha eziko.

Xa ubushushu bokucima ukucima ngokubanzi kuthambekele kumda ophezulu, ixesha lokubamba i-aluminium lifutshane ngokuhambelanayo; Emva kwe-extrusion ephezulu yokushisa, idigri ye-deformation inkulu, ixesha lokubamba lifutshane. Kwiprofayili ye-aluminium yangaphambili, ngenxa yokuba isigaba sokuqinisa sihamba ngokukhawuleza kwaye sinzima, izinga lokuchithwa kwesigaba sokuqinisa liyacotha, ngoko ixesha lokubamba lide ngokuhambelanayo.

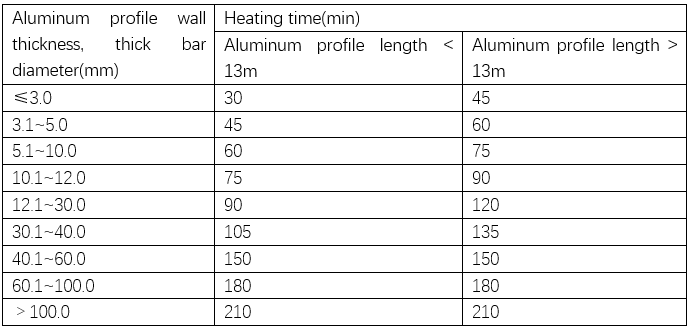

Ixesha lokubamba iiprofayili ze-aluminium ezivuthayo emoyeni oshushu zihluke kakhulu kwiibhafu zetyuwa, kwaye ixesha lokufudumala kwiibhafu zetyuwa lifutshane kakhulu. Uninzi lweeprofayili ze-aluminiyam okanye imivalo zisebenzisa izixhobo zokucima umoya ezithe nkqo, kwaye ixesha lokubamba libalwa xa ubushushu bomphezulu wesinyithi okanye ubushushu beziko lufikelela kumda ophantsi wobushushu bokucima. Itheyibhile 1 idwelisa amaxesha okufudumeza kunye nokubamba iiprofayili ze-aluminium kunye nemivalo yobukhulu obuhlukeneyo kwisithando sokucima umoya.

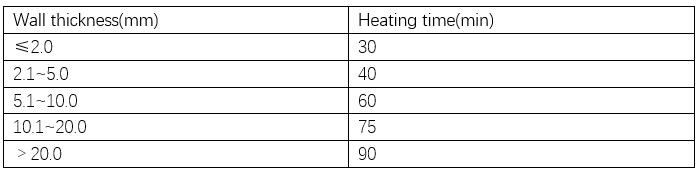

Itheyibhile 2 ibonisa ukufudumeza kunye nokubamba ixesha lemibhobho enobunzima obuhlukeneyo bodonga kwi-vertical air quenching furnace. Ixesha lokubamba ukucima ukushisa kufuneka liqinisekise ukuba isigaba sokuqiniswa sichithwa ngokupheleleyo ukwenzela ukufumana umphumo wokomeleza ubuninzi, kodwa ixesha lokufudumala akufanele libe lide kakhulu, kwezinye iimeko, liya kunciphisa ukusebenza kweprofayili.

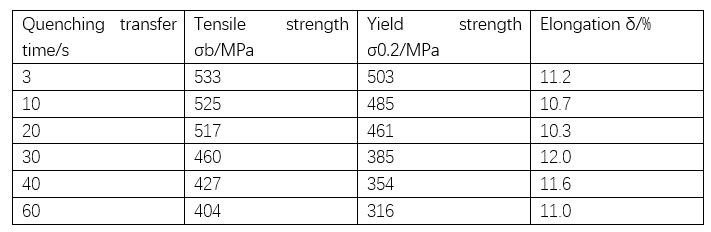

Iiprofayili ezininzi ze-aluminium eziphathwa ngobushushu kwimizi-mveliso ezifana ne-2A12, 7A04 kunye nezinye iiprofayili zamandla aphezulu azikwazi ukucinywa emoyeni njengeprofayili ye-aluminium yezakhiwo ezifana ne-6063 alloy, oko kukuthi, izinga lokupholisa elincinane linokuthintela imvula yezigaba zokuqinisa. Ziya kukhutshwa kwisithando somlilo sokucima, zidluliselwe kwi-tank yamanzi yokucima, kwaye zipholile emoyeni imizuzwana embalwa, kuya kubakho imvula yezigaba zokuqinisa, eziya kuchaphazela umphumo wokuqinisa. Itheyibhile 3 idwelisa imiphumo yamaxesha ahlukeneyo okudluliselwa kwe-7A04 i-alloy kwiipropati zomatshini emva kokucima.

(Itheyibhile 3 - 7A04 i-alloy yokucima umphumo wexesha lokudlulisa kwiipropati zemishini yeeprofayili ze-aluminium)

Ngako oko, ixesha lokucima ukucima enye yeeparitha zenkqubo ekufuneka icaciswe kwinkqubo yokucima iiprofayili ze-aluminium, oko kukuthi, ukuhanjiswa kweeprofayili ze-aluminium ukusuka kwisithando sokucima ukuya kwindawo yokucima kufuneka kugqitywe ngaphakathi kwexesha elichaziweyo eliphezulu lokudlulisa, elibizwa ngokuba lixesha eliphezulu elivumelekileyo lokudlulisa okanye ukucima ixesha lokulibaziseka. Eli xesha lihambelana nokubunjwa kwe-alloy, imilo yeprofayili, kunye neqondo lokuzenzekelayo kwezixhobo zokusebenza. Ukuba iimeko zivuma, okukhona lifutshane ixesha lokucinywa lokudluliselwa, kokukhona lingcono. Imimiselo yenkqubo ngokubanzi: ixesha lokudluliselwa kweeprofayili ezincinci akufanele lidlule i-20s, iiprofayili ezinkulu okanye i-batch ezicinyiweyo ze-aluminium akufanele zidlule i-40; kwiiprofayili ezinzima ezifana ne-7A04, ixesha lokudluliselwa akufanele lidlule i-15s.

Ihlelwe nguMay Jiang esuka kwiMAT Aluminium

Ixesha lokuposa: Oct-21-2023