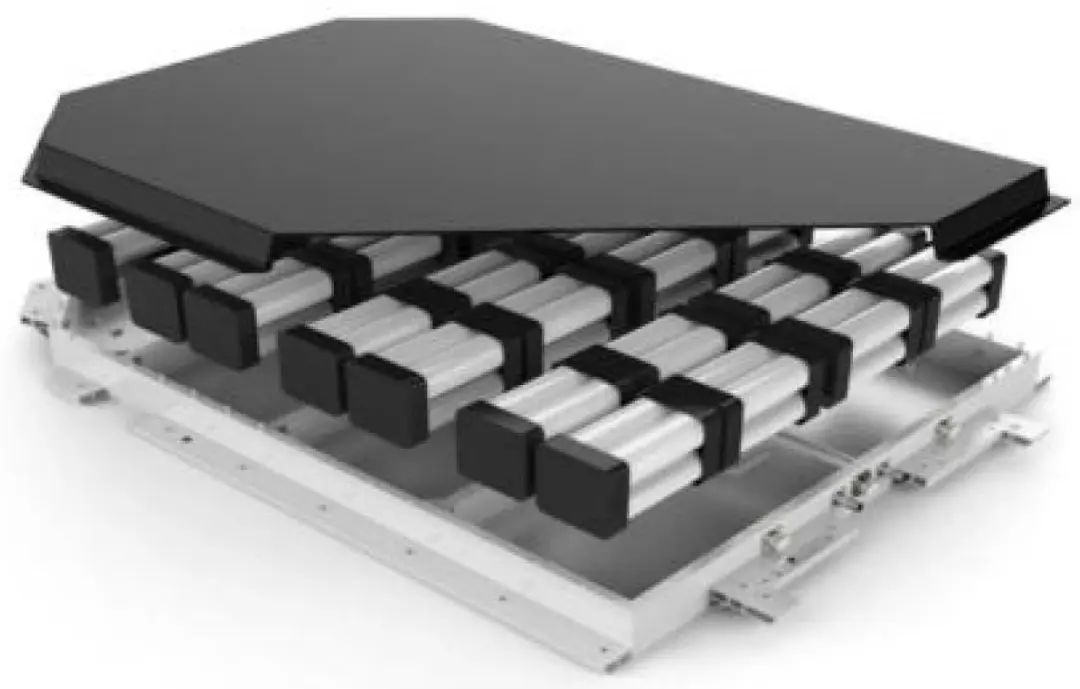

Ibhetri iyona nto iphambili kwisithuthi sombane, kwaye ukusebenza kwayo kumisela izikhombisi zobugcisa ezifana nobomi bebhetri, ukusetyenziswa kwamandla, kunye nobomi benkonzo yesithuthi sombane. Itreyi yebhetri kwimodyuli yebhetri licandelo eliphambili elenza imisebenzi yokuthwala, ukukhusela, kunye nokupholisa. Ipakethi yebhetri ye-modular ihlelwe kwi-tray yebhetri, igxininiswe kwi-chassis yemoto ngokusebenzisa i-tray yebhetri, njengoko kuboniswe kuMzobo 1. Ekubeni ifakwe phantsi komzimba wesithuthi kwaye indawo yokusebenza inzima, i-tray yebhetri kufuneka ibe nomsebenzi wokuthintela impembelelo yamatye kunye ne-puncture ukukhusela imodyuli yebhetri ukuba yonakaliswe. Itreyi yebhetri yinxalenye yokhuseleko olubalulekileyo lwezithuthi zombane. Oku kulandelayo kwazisa inkqubo yokubumba kunye noyilo lokungunda lweetreyi zebhetri yealluminiyam kwizithuthi zombane.

Umzobo 1 (itreyi yebhetri yeAluminiyam)

1 Uhlalutyo lwenkqubo kunye noyilo lokungunda

1.1 Uhlalutyo lokudlala

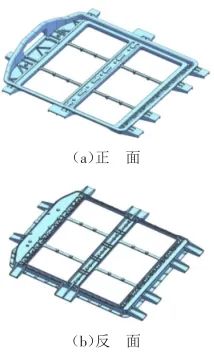

I-aluminium i-alloy yebhetri ye-tray yezithuthi zombane iboniswe kwi-Figure 2. Imilinganiselo yonke i-1106mm × 1029mm × 136mm, ubukhulu bodonga olusisiseko yi-4mm, umgangatho wokuphosa malunga ne-15.5kg, kunye nomgangatho wokuphosa emva kokucubungula malunga ne-12.5kg. Izinto eziphathekayo yi-A356-T6, Amandla okuqina ≥ 290MPa, amandla esivuno ≥ 225MPa, elongation ≥ 6%, ukuqina kweBrinell ≥ 75~90HBS, idinga ukuhlangabezana nokuxinwa komoya kunye neemfuno ze-IP67&IP69K.

Umfanekiso 2 (itreyi yebhetri yeAluminiyam)

1.2 Uhlalutyo lwenkqubo

Uxinzelelo oluphantsi lokuphosa ukufa yindlela ekhethekileyo yokuphosa phakathi koxinzelelo kunye nokuphosa ubunzima. Ayinayo nje inzuzo yokusebenzisa iimbumba zetsimbi zombini, kodwa ineempawu zokuzaliswa okuzinzile. Uxinzelelo oluphantsi lwe-die casting luneenzuzo zokuzaliswa kwesantya esisezantsi ukusuka ezantsi ukuya phezulu, kulula ukulawula isantya, impembelelo encinci kunye ne-splash ye-aluminium engamanzi, i-slag encinci ye-oxide, ukuxinana kwezicubu eziphezulu kunye neempawu eziphezulu zemishini. Ngaphantsi koxinzelelo oluphantsi lokuphosa ukufa, i-aluminium engamanzi izaliswe kakuhle, kwaye ukuphosa kuyaqina kwaye kukhazimle phantsi koxinzelelo, kunye nokuphosa kunye nesakhiwo esixineneyo esiphezulu, iipropati eziphezulu zoomatshini kunye nenkangeleko enhle inokufumaneka, efanelekile ukwenza ii-castings ezinkulu ezibhityileyo.

Ngokweempawu zoomatshini ezifunekayo ngokugalelwa, izinto zokugalela yi-A356, ezinokuhlangabezana neemfuno zabathengi emva kokunyangwa kwe-T6, kodwa ukugalelwa kwamanzi alo mbandela ngokubanzi kufuna ulawulo olufanelekileyo lobushushu bokubumba ukuvelisa i-castings enkulu kunye nencinci.

1.3 Inkqubo yokugalela

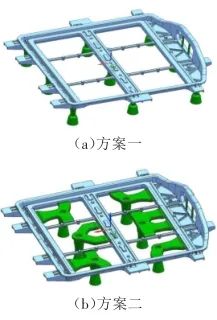

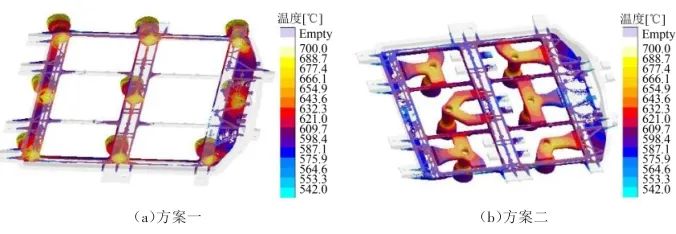

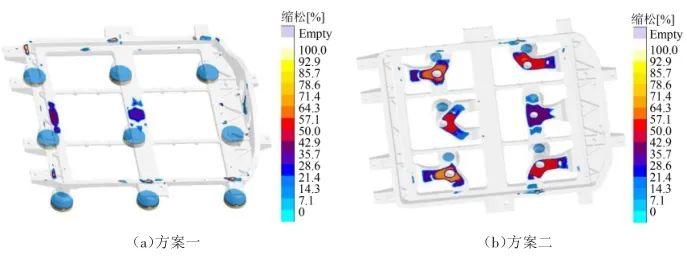

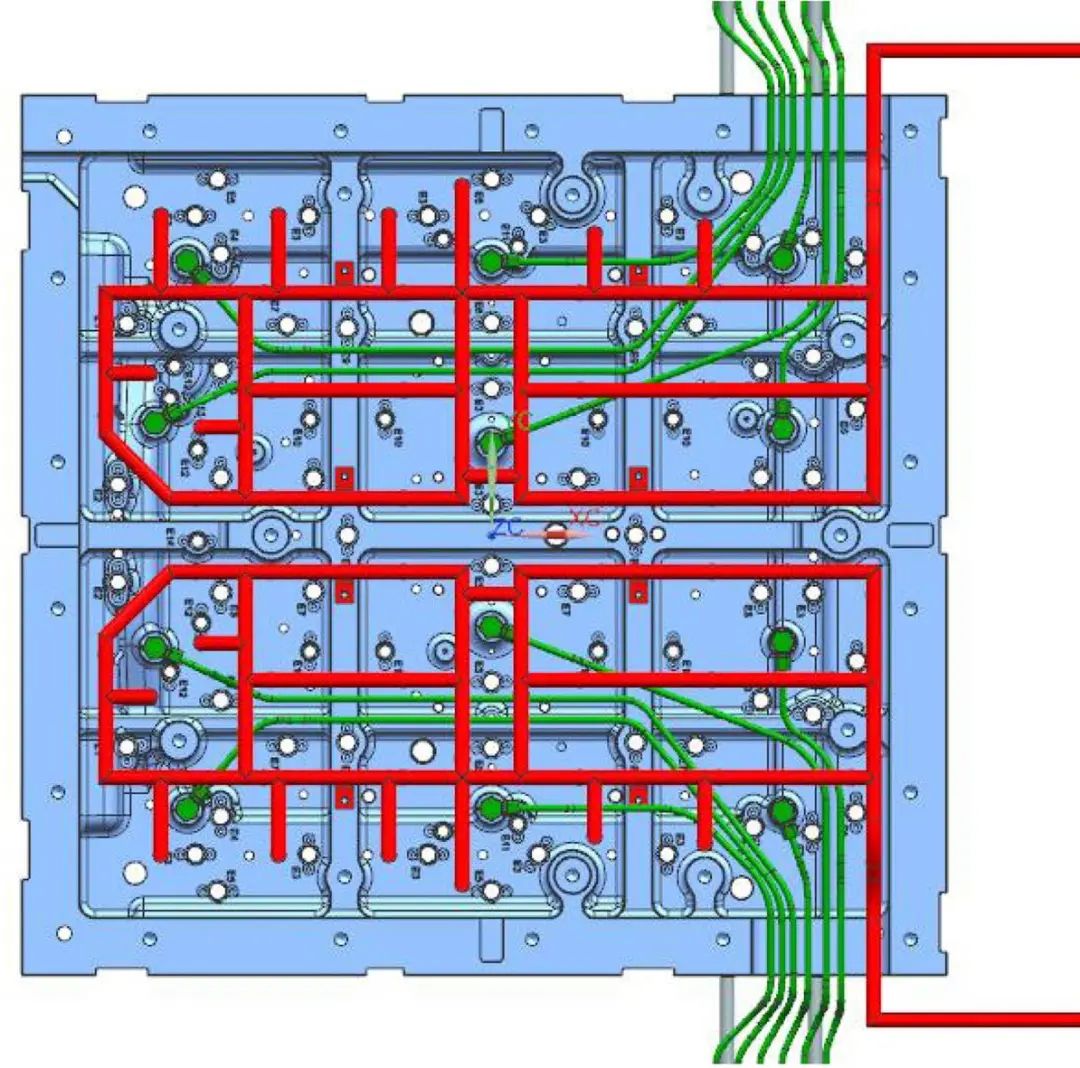

Ngokujonga iimpawu zokuphosa ezinkulu kunye ezincinci, amasango amaninzi kufuneka ayilwe. Ngexesha elifanayo, ukwenzela ukuba kuqinisekiswe ukuzaliswa kakuhle kwe-aluminium ye-liquid, iziteshi zokuzalisa zongezwa kwifestile, ekufuneka isuswe nge-post-processing. Iinkqubo ezimbini zenkqubo yokugalela ziyilwe kwinqanaba lokuqala, kwaye iskimu ngasinye sathelekiswa. Njengoko kuboniswe kwi-Figure 3, iskimu se-1 silungiselela amasango angama-9 kwaye songeza iziteshi zokutya kwifestile; iskimu se-2 silungiselela iingcango ezi-6 ezigalela ukusuka kwicala lokubunjwa ukuze zenziwe. Uhlalutyo lwe-CAE lokulinganisa luboniswe kwi-Figure 4 kunye ne-Figure 5. Sebenzisa iziphumo zokulinganisa ukulungelelanisa isakhiwo sokubumba, zama ukuphepha impembelelo embi yoyilo lwe-mold kumgangatho we-castings, ukunciphisa amathuba okuphosa iziphene, kunye nokunciphisa umjikelezo wophuhliso lwe-castings.

Umzobo 3 (Ukuthelekiswa kweenkqubo ezimbini zenkqubo yoxinzelelo oluphantsi

Umzobo 4 (Uthelekiso lwentsimi yobushushu ngexesha lokuzaliswa)

Umzobo 5 (Ukuthelekiswa kwe-shrinkage porosity defects emva kokuqina)

Iziphumo zokulinganisa ezi zicwangciso zimbini zingasentla zibonisa ukuba i-aluminium engamanzi kwi-cavity ihambela phezulu malunga ne-parallel, ehambelana nethiyori yokuzaliswa okuhambelanayo kwe-aluminium engamanzi iyonke, kunye neengxenye ze-shrinkage ze-porosity eziye zasombululwa ngokuqinisa ukupholisa kunye nezinye iindlela.

Izibonelelo zezicwangciso ezimbini: Ukuqwalasela kwiqondo lokushisa kwe-aluminium engamanzi ngexesha lokuzaliswa okufaniswayo, ukushisa kwesiphelo se-distal ye-casting eyenziwe yi-scheme ye-1 inokulingana okuphezulu kunokwakheka kwe-2, ehambelana nokuzaliswa komgodi. I-casting eyenziwe yi-scheme ye-2 ayinayo intsalela yesango njenge-scheme 1. I-shrinkage porosity ingcono kune-scheme ye-1.

Ukungalungi kwezi zicwangciso zimbini: Ngenxa yokuba isango licwangciswe kwi-casting eya kwenziwa kwi-scheme ye-1, kuya kubakho intsalela yesango kwi-casting, eya kwandisa malunga ne-0.7ka xa kuthelekiswa nokuphosa kwasekuqaleni. ukusuka kubushushu be-aluminium engamanzi kwiskimu 2 ukuzaliswa okufanisiweyo, ubushushu be-aluminium engamanzi kwisiphelo se-distal sele buphantsi, kwaye ukulinganisa kuphantsi kwemeko efanelekileyo yeqondo lokushisa lokungunda, ngoko ke umthamo wokuhamba kwe-aluminium engamanzi unokungonelanga kwimeko yokwenyani, kwaye kuya kubakho ingxaki yobunzima ekubumbeni ukubunjwa.

Idityaniswe nohlalutyo lwemiba eyahlukeneyo, iskimu 2 sakhethwa njengenkqubo yokugalela. Ngokubhekiselele kwiintsilelo zeskimu se-2, inkqubo yokuthulula kunye nenkqubo yokufudumala iphuculwe kwi-design mold. Njengoko kuboniswe kwi-Figure 6, i-overflow riser yongezwa, enenzuzo yokuzaliswa kwe-aluminium engamanzi kwaye iyanciphisa okanye igweme ukwenzeka kweziphene kwii-castings ezibunjiweyo.

Umzobo 6 (Inkqubo yokugalela ephuculweyo)

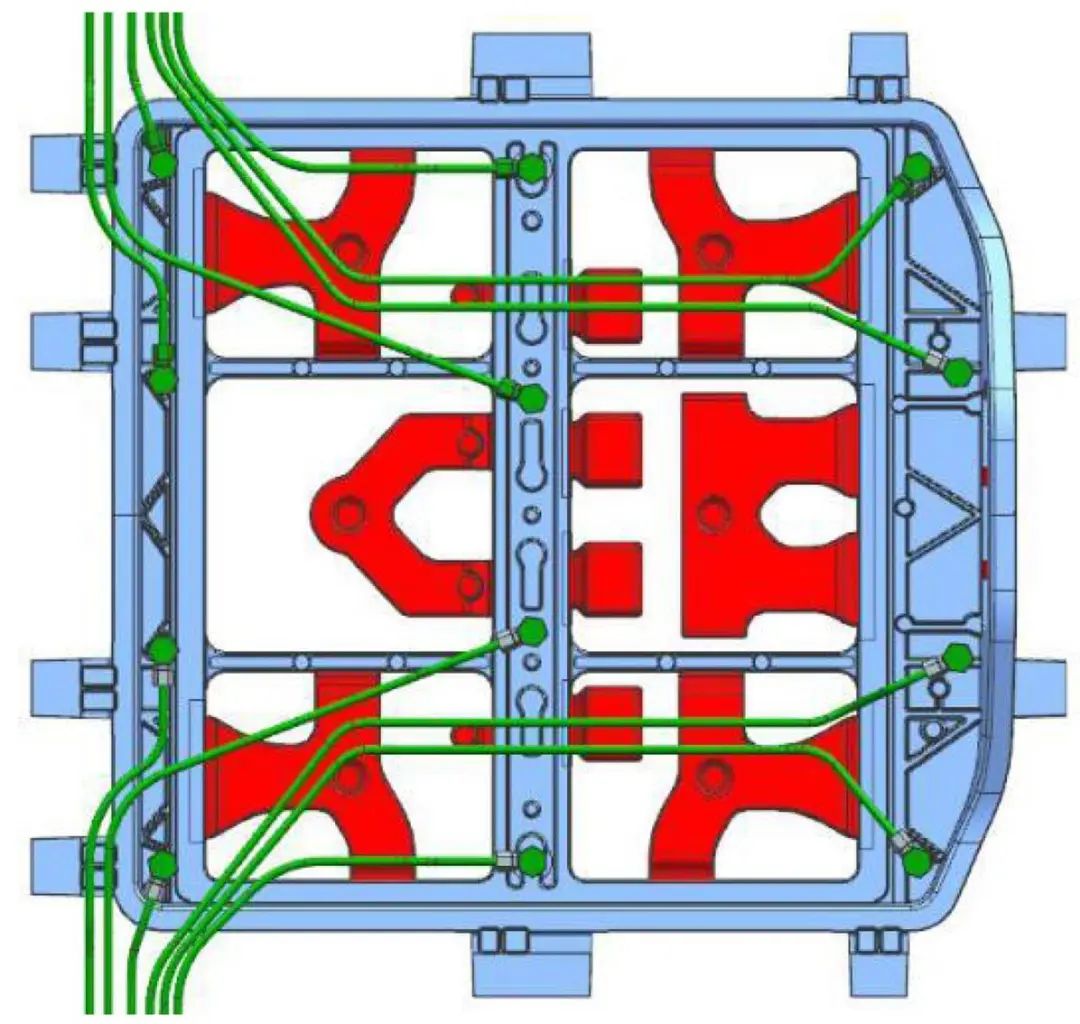

1.4 Inkqubo yokupholisa

Iindawo ezithwele uxinzelelo kunye neendawo ezineemfuno eziphezulu zokusebenza kwemishini yokuphosa kufuneka zipholile ngokufanelekileyo okanye zondliwe ukuze zigweme i-shrinkage porosity okanye i-thermal cracking. Ubukhulu bodonga olusisiseko lokubunjwa ngu-4mm, kwaye ukuqina kuya kuchaphazeleka ngokuchithwa kobushushu besikhunta ngokwayo. Kwiindawo zayo ezibalulekileyo, inkqubo yokupholisa imiselwe, njengoko kuboniswe kuMzobo 7. Emva kokuba ukuzaliswa kugqityiwe, dlulisa amanzi ukupholisa, kwaye ixesha elithile lokupholisa lifuna ukulungiswa kwindawo yokuthulula ukuze kuqinisekiswe ukuba ukulandelelana kokuqina kuqulunqwe ukusuka kumgama wesango ukuya ekupheleni kwesango, kwaye isango kunye nokunyuka kuqiniswe ekupheleni ukuze kufezekiswe umphumo wokutya. Icandelo elinodonga olutyebileyo luthatha indlela yokongeza ukupholisa kwamanzi kwi-insert. Le ndlela inesiphumo esingcono kwinkqubo yokwenyani yokuphosa kwaye inokuphepha i-shrinkage porosity.

Umfanekiso 7 (Inkqubo yokupholisa)

1.5 Inkqubo yokukhupha umoya

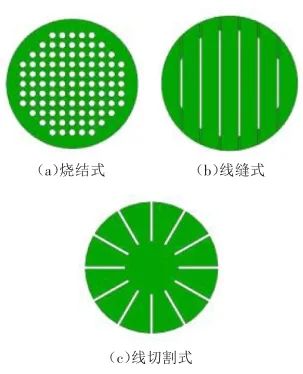

Ekubeni i-cavity ye-low-high pressure die cast casting metal ivaliwe, ayinayo i-air permeability efana ne-sand molds, kwaye ayipheli ngokunyuka kwi-gravity casting ngokubanzi, ukukhupha i-cavity ye-low-pressure casting cavity kuya kuchaphazela inkqubo yokuzaliswa kwe-aluminium engamanzi kunye nomgangatho we-castings. Uxinzelelo oluphantsi lwe-die casting mold lunokuphela ngokusebenzisa izithuba, i-grooves yokukhupha kunye ne-exhaust plugs kwindawo yokuhlukana, intonga yokutyhala njl.

Ukuyila ubungakanani bombhobho kwindlela yokukhupha kufuneka kube yinto efanelekileyo yokukhupha ngaphandle kokugqithisa, inkqubo yokukhupha ingqiqo inokuthintela ukuphosa kwiiphene ezifana nokuzaliswa okunganeleyo, indawo ekhululekile, kunye namandla aphantsi. Indawo yokugqibela yokuzalisa i-aluminium engamanzi ngexesha lokuthulula, njengokuphumla kwecala kunye nokunyuka kwesikhunta esiphezulu, kufuneka kuxhotyiswe ngegesi yokukhupha. Ngenxa yokuba i-aluminiyam elulwelo iqukuqela ngokulula kwisithuba sokukhupha iplagi kwinkqubo eyiyo yoxinzelelo oluphantsi lokuphosa ukufa, nto leyo ekhokelela kwimeko yokuba iplagi yomoya itsalwe xa kuvulwe ukungunda, iindlela ezintathu zamkelwe emva kwemizamo emininzi kunye nophuculo: Indlela yoku-1 isebenzisa iplagi yomoya yesinyithi, njengoko kubonisiwe kuMfanekiso 8 (ixabiso eliphezulu) ; Indlela yesi-2 isebenzisa iplagi yokukhupha i-seam ene-gap ye-0.1 mm, njengoko kuboniswe kwi-Figure 8 (b), into engalunganga kukuba i-exhaust seam ivalwe ngokulula emva kokutshiza ipeyinti; Indlela ye-3 isebenzisa iplagi yokukhupha i-wire-cut, i-gap yi-0.15 ~ 0.2 mm, njengoko kuboniswe kuMzobo 8 (c). Izinto ezingeloncedo kukusebenza okuphantsi kunye neendleko eziphezulu zokwenziwa kwemveliso. Iiplagi ezahlukeneyo zokukhupha kufuneka zikhethwe ngokwendawo yokwenyani yokuphosa. Ngokubanzi, iiplagi ze-sintered kunye ne-wire-cut vent vent zisetyenziselwa umgodi wokuphosa, kwaye uhlobo lomthungo lusetyenziselwa intloko yesanti engundoqo.

Umzobo 8 (iintlobo ezi-3 zeeplagi zokukhupha ezilungele ukuphoswa koxinzelelo oluphantsi)

1.6 Inkqubo yokufudumeza

Ukusatywa kukhulu ngokobukhulu kwaye kubhityile kububanzi bodonga. Kuhlalutyo lokuhamba kwe-mold, izinga lokuhamba kwe-aluminium engamanzi ekupheleni kokuzaliswa akwanelanga. Isizathu kukuba i-aluminiyam engamanzi ide kakhulu ukuba ihambe, ubushushu buhla, kwaye i-aluminium engamanzi iqina kwangaphambili kwaye ilahlekelwa amandla ayo okuhamba, i-cold shut okanye ukugalela okungonelanga kwenzeka, i- riser yokufa ephezulu ayiyi kuba nako ukufikelela kwisiphumo sokutyisa. Ngokusekwe kwezi ngxaki, ngaphandle kokutshintsha ukutyeba kodonga kunye nokumila kokugalelwa, nyusa ubushushu be-aluminium engamanzi kunye nobushushu bokungunda, phucula ubumanzi be-aluminiyam engamanzi, kunye nokusombulula ingxaki yokuvala okubandayo okanye ukugalelwa okunganeleyo. Nangona kunjalo, ubushushu obugqithisileyo be-aluminiyam yolwelo kunye nobushushu bomngundo buya kuvelisa iindawo ezintsha zokuhlangana kwe-thermal okanye i-shrinkage porosity, ekhokelela kwiipinhole zenqwelomoya ezigqithisileyo emva kokuphoswa. Ke ngoko, kuyafuneka ukuba ukhethe ubushushu obufanelekileyo be-aluminium engamanzi kunye nobushushu obufanelekileyo bokungunda. Ngokwamava, ubushushu be-aluminium engamanzi bulawulwa malunga ne-720 ℃, kwaye ubushushu bokubumba bulawulwa kwi-320 ~ 350 ℃.

Ngokujonga umthamo omkhulu, ubukhulu bodonga oluncinci kunye nokuphakama okuphantsi kokuphosa, inkqubo yokufudumala ifakwe kwindawo ephezulu yokubumba. Njengoko kuboniswe kwi-Figure 9, isalathiso somlilo sijongene nezantsi kunye necala lokubumba ukutshisa indiza ephantsi kunye necala lokuphosa. Ngokwemeko yokugalela kwisiza, lungisa ixesha lokufudumeza kunye nomlilo, lawula ubushushu bendawo ephezulu yokubumba kwi-320 ~ 350 ℃, qinisekisa umbane we-aluminium engamanzi ngaphakathi koluhlu olufanelekileyo, kwaye wenze i-aluminium yolwelo igcwalise i-cavity kunye nokunyuka. Ekusetyenzisweni okwenyani, inkqubo yokufudumeza inokuqinisekisa ngokufanelekileyo ubumanzi be-aluminium engamanzi.

Umzobo 9 (Inkqubo yokufudumeza)

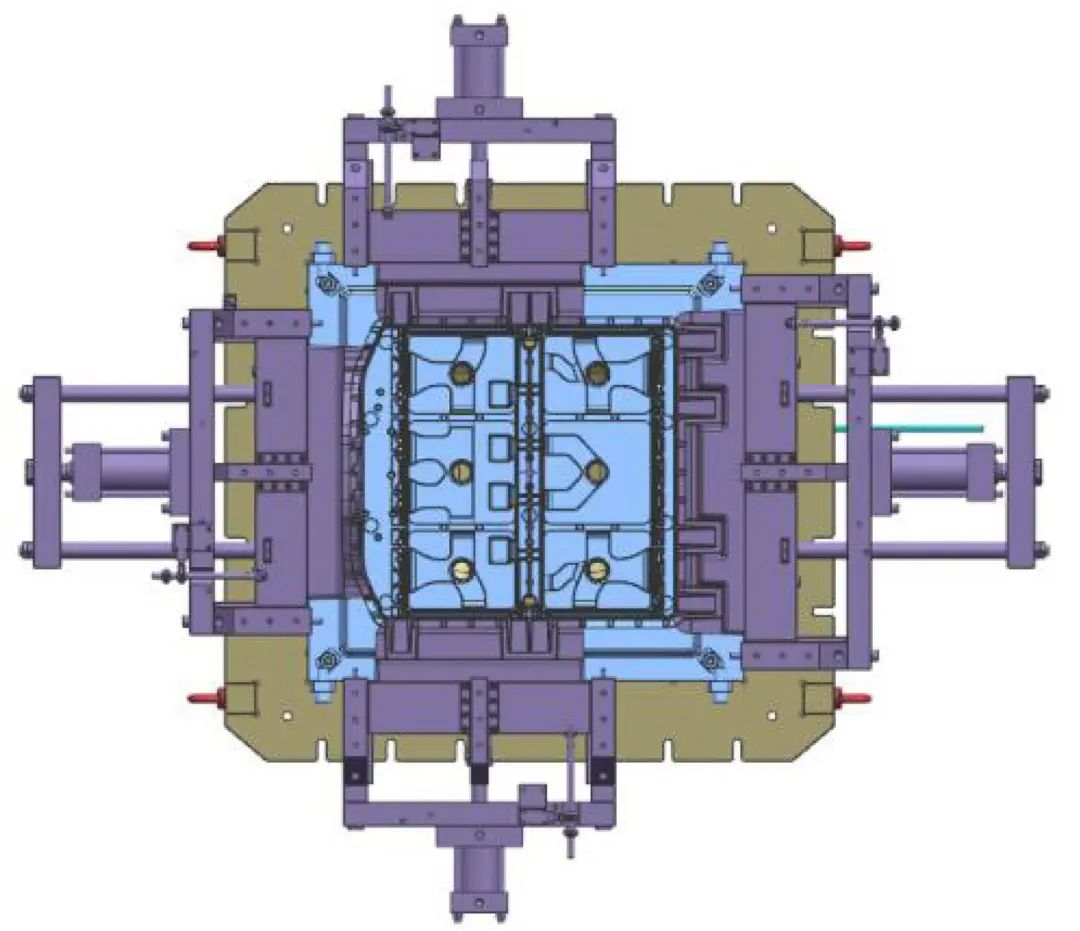

2. Ubume bokubumba kunye nomgaqo wokusebenza

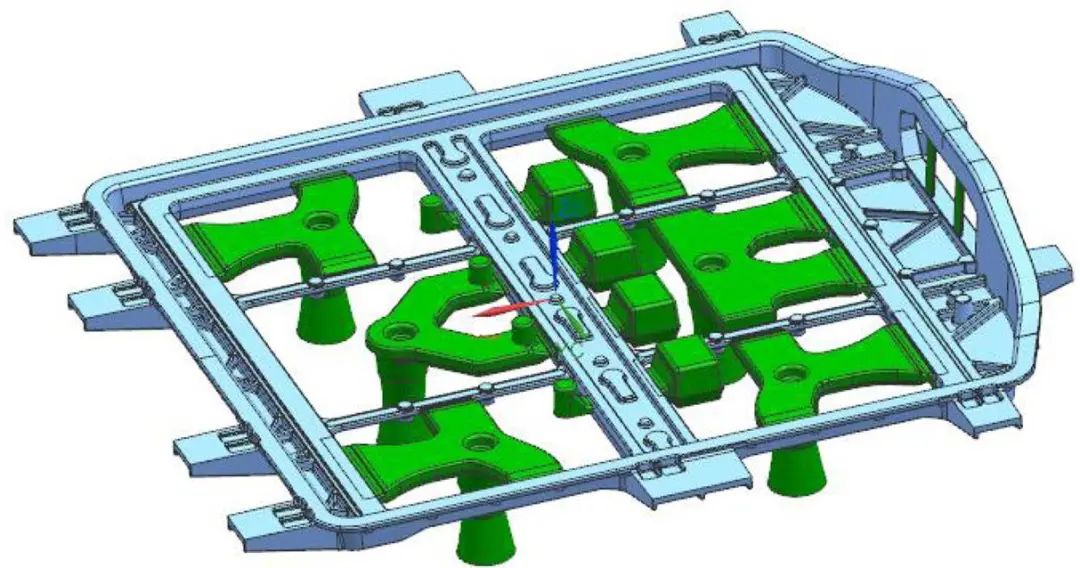

Ngokwenkqubo yokuphosa ingcinezelo ephantsi, idityaniswe neempawu zokugalela kunye nesakhiwo sezixhobo, ukwenzela ukuba kuqinisekiswe ukuba i-casting ebunjiweyo ihlala kwi-mold ephezulu, i-front, i-back, i-ekhohlo kunye ne-right core-tsala izakhiwo zenzelwe kwi-mold ephezulu. Emva kokuba i-casting yenziwe kwaye iqiniswe, i-molds ephezulu kunye nesezantsi ivulwa kuqala, kwaye emva koko idonsa i-core kwiindlela ezi-4, kwaye ekugqibeleni ipleyiti ephezulu ye-mold ephezulu ityhala ngaphandle ukuphosa okwenziweyo. Ulwakhiwo lokungunda luboniswe kuMfanekiso we-10.

Umfanekiso we-10 (isakhiwo sokungunda)

Ihlelwe nguMay Jiang esuka kwiMAT Aluminium

Ixesha lokuposa: May-11-2023