I-Anodizing yinkqubo esetyenziselwa ukwenza ifilimu ye-aluminium oxide kumphezulu we-aluminiyam okanye iimveliso ze-aluminium alloy. Kubandakanya ukubeka i-aluminium okanye i-aluminium alloy imveliso njenge-anode kwisisombululo se-electrolyte kunye nokusebenzisa umbane wangoku ukwenza ifilimu ye-aluminium oxide. I-Anodizing iphucula ukuxhathisa kwe-corrosion, ukumelana nokunxiba, kunye neempawu zokuhombisa zeeprofayili ze-aluminium. Ngexesha lenkqubo ye-anodizing yeeprofayili ze-aluminium, iimpawu ezininzi zesiphene eziqhelekileyo zingenzeka. Ngokusisiseko masiqonde oonobangela beziphene ezibonwayo. Ukonakala kwezinto, ukungcoliseka kwebhafu, imvula yezigaba zesibini ze-alloy, okanye iziphumo zegalvanic zinokukhokelela kwiziphene ezibonwayo. Zichazwa ngolu hlobo lulandelayo:

1.I-Acid okanye i-alkali etching

Phambi kwe-anodizing, imathiriyeli ye-aluminiyam inokugqweswa yi-asidi okanye ulwelo lwe-alkaline, okanye ichatshazelwe yi-asidi okanye umsi we-alkaline, okukhokelela ekubeni kubekho amabala amhlophe phezu komhlaba. Ukuba umhlwa ubukhali, iindawo zokugalela ezinkulu zinokuvela. Kunzima ukugqiba ngeso lenyama ukuba i-corrosion ibangelwa i-asidi okanye i-alkali, kodwa iyakwazi ukuhlukaniswa ngokulula ngokuqwalasela i-cross-section yendawo ebolileyo phantsi kwe-microscope. Ukuba umphantsi womngxuma ungqukuva kwaye ngaphandle kokuhlwa kwe-intergranular, kubangelwa ukukrolwa kwealkali. Ukuba i-bottom ayifani kwaye ihamba kunye ne-intergranular corrosion, enemingxuma enzulu, ibangelwa yi-acid etching. Ukugcinwa okungafanelekanga kunye nokuphathwa kwefektri nako kunokukhokelela kulolu hlobo lokubola. Umphunga we-Acid ophuma kwiikhemikhali zokupholisha okanye ezinye iziqhumiso ezine-asidi, kunye ne-chlorinated organic degreasers, yimithombo ye-asidi etching. Ukucinywa kwealkali okuqhelekileyo kubangelwa kukusasazwa kunye nokutshizwa kodaka, uthuthu lwesamente, kunye nolwelo lokuhlamba lwealkaline. Xa isizathu siqinisekisiwe, ukomeleza ulawulo lweenkqubo ezahlukeneyo kumzi-mveliso kunokusombulula ingxaki.

2.I-atmospheric corrosion

Iiprofayili ze-aluminiyam ezivezwe kumoya ofumayo zinokuvelisa amabala amhlophe, ahlala elungelelaniswa ngobude ecaleni kwemigca yokungunda. I-atmospheric corrosion ayinzima njenge-asidi okanye i-alkali etching kwaye inokususwa ngeendlela zoomatshini okanye i-alkaline yokuhlamba. I-atmospheric Corrosion ubukhulu becala ayiyondawo kwaye ithande ukwenzeka kwimigangatho ethile, efana neendawo zobushushu obusezantsi apho umphunga wamanzi ujiya ngokulula okanye kumphezulu ophezulu. Xa i-corrosion ye-atmospheric inzima kakhulu, i-cross-section of the pitting spots ibonakala njengamakhowa aguqulwe. Kule meko, ukuhlamba i-alkaline akukwazi ukuphelisa iindawo zokubeka kwaye zingawandisa. Ukuba i-atmospheric corrosion inqunywe, iimeko zokugcina kwifektri kufuneka zihlolwe. Izinto ze-aluminiyam akufanele zigcinwe kwiindawo ezinamaqondo obushushu aphantsi kakhulu ukuthintela ukunyuswa komphunga wamanzi. Indawo yokugcina kufuneka yome, kwaye iqondo lokushisa kufuneka lifane ngokusemandleni.

3.Umhlwa wephepha (amabala amanzi)

Xa iphepha okanye ikhadibhodi ifakwe phakathi kwezinto ze-aluminium okanye isetyenziselwa ukupakisha, ikhusela ukukrazula. Nangona kunjalo, ukuba iphepha liba manzi, iindawo zokubola zivela kumphezulu we-aluminiyam. Xa kusetyenziswa amakhadibhodi e-corrugated, imigca eqhelekileyo yeendawo zokubola ibonakala kwiindawo zokuqhagamshelana nebhodi yebhodi. Nangona iziphene ngamanye amaxesha zinokubonakala ngokuthe ngqo kumphezulu we-aluminium, zihlala zibonakala ngakumbi emva kokuhlamba kwe-alkaline kunye ne-anodizing. La mabala anzulu ngokubanzi kwaye kunzima ukuwasusa ngeendlela zoomatshini okanye ngokuhlamba ialkaline. Iphepha (ibhodi) i-corrosion ibangelwa i-acid ions, ikakhulukazi i-SO42- kunye ne-Cl-, ekhoyo kwiphepha. Ngoko ke, ukusebenzisa iphepha (ibhodi) ngaphandle kwekloridi kunye ne-sulfates kunye nokuphepha ukungena kwamanzi ziindlela ezisebenzayo zokukhusela iphepha (ibhodi) ukubola.

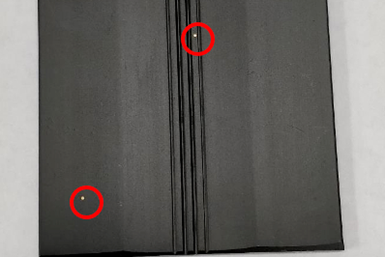

4.Ukucoca umhlwa kwamanzi (ekwaziwa ngokuba yi-snowflake corrosion)

Emva kokuhlamba i-alkaline, i-chemical polishing, okanye i-sulfuric acid pickling, ukuba amanzi ahlanjululwayo aqulethe ukungcola, kunokubangela ukuba kubekho amabala anjengenkwenkwezi okanye amhlophe phezu komhlaba. Ubunzulu bomhlwa abunzulu. Olu hlobo lwe-corrosion lwenzeka xa amanzi okucoca engcoliseke kakhulu okanye xa izinga lokuhamba kwe-rinsing echichimayo liphantsi. Ifana neekristale ezimile okwekhephu ngenkangeleko, yiyo loo nto igama elithi "snowflake corrosion." Isizathu sokusabela phakathi kokungcola kwe-zinc kwi-aluminium kunye ne-SO42- kunye ne-Cl-kumanzi okucoca. Ukuba i-insulation yetanki ihlwempuzekile, iziphumo ze-galvanic zinokunyusa esi siphene. Ngokutsho kwemithombo yangaphandle, xa umxholo weZn kwi-aluminium alloy mkhulu kune-0.015%, i-Cl-kumanzi okucoca iphezulu kune-15 ppm, olu hlobo lwe-corrosion lunokwenzeka. Ukusebenzisa i-nitric acid yokukhetha okanye ukongeza i-0.1% ye-HNO3 kumanzi okucoca unokuphelisa.

5.I-Chloride Corrosion

Ubukho besixa esincinci sekloridi kwi-asidi ye-anodizing yokuhlamba i-sulfuric kunokukhokelela kwi-corrosion ye-pitting. Imbonakalo yophawu yimingxuma enzulu emile okwenkwenkwezi emnyama, egxininiswe ngakumbi emaphethelweni nakwiikona zesixhobo sokusebenza okanye kwezinye iindawo ezinoxinzelelo oluphezulu lwangoku. Iindawo zokugoba azikho ifilimu ye-anodized, kwaye ubukhulu befilimu kwiindawo ezisele "eziqhelekileyo" zingaphantsi kwexabiso elilindelekileyo. Isiqulatho setyuwa eninzi emanzini etephu ngowona mthombo ungundoqo wongcoliseko kwindawo yokuhlambela.

6.I-galvanic corrosion

Kwitanki ene-energized (i-anodizing okanye i-electrolytic coloring), iimpembelelo zegalvanic phakathi kwendawo yokusebenza kunye netanki (i-tank yensimbi), okanye iimpembelelo zamanzi ajikelezayo kwitanki engenamandla (ukuhlanjululwa okanye ukutywinwa), kunokubangela okanye kubangele ukubola kwe-pitting.

Ihlelwe nguMay Jiang esuka kwiMAT Aluminium

Ixesha lokuposa: Dec-15-2023