1 Inkcazo yeziganeko zesiphene

Xa ukhupha iiprofayili ze-cavity, intloko isoloko ikhutshiwe, kwaye izinga eliphosakeleyo liphantse li-100%. Ubume obuqhelekileyo beprofayile buhamba ngolu hlobo lulandelayo:

2 Uhlalutyo lwangaphambili

2.1 Ukuqwalasela indawo yesiphene kunye nokumila kwesiphene, i-delamination kunye ne-peeling.

2.2 Unobangela: Ngenxa yokuba ulusu lwentonga yokuphosa yangaphambili yaqengqeleka kumngxuma wokungunda, ukungahambelani, ukuxobuka, kunye nemathiriyeli ebolileyo yavela kwintloko yokukhutshwa kwentonga yokuphosa elandelayo.

3 Ukufunyanwa kunye nohlalutyo

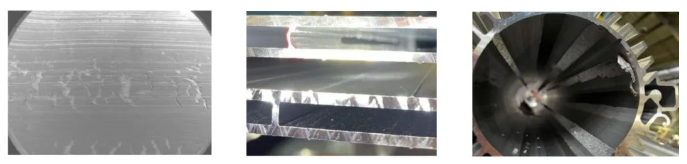

Imifanekiso ye-electron microscope yokwandisa okuphantsi, ukuphakama okuphezulu kunye neziphene ezinqamlekileyo zentonga yokuphosa zenziwa ngokulandelanayo.

3.1 Intonga yokuphosa ukukhulisa okuphantsi

I-intshi eyi-11 6060 intonga yokuphosa ukwandiswa komgangatho ophantsi ulwahlulo lomphezulu 6.08mm

3.2 Intonga yokuphosa ukukhulisa okuphezulu

Kufuphi kwi-epidermis Ukwahlula umaleko wokwahlula indawo yomgca wokwahlulahlula

Intonga yokuphosa 1/2 isikhundla

3.3 Ukuskena ngemakroskopu ye-Electron yeziphene

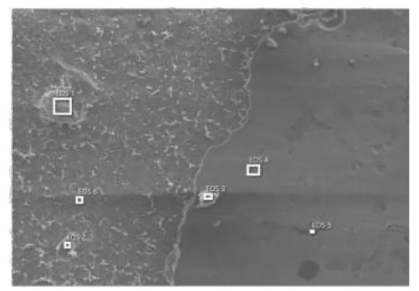

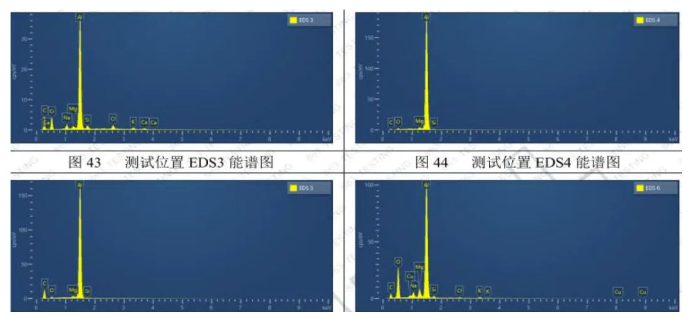

Yandisa indawo enesiphako ngamaxesha angama-200

Umzobo we-energy spectrum

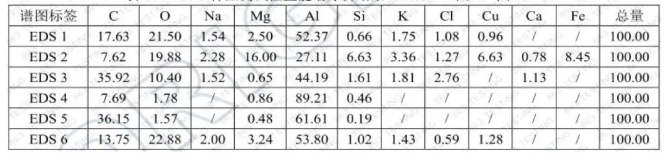

Uhlalutyo lwecandelo le-EDS

4 Inkcazo emfutshane yeziphumo zohlalutyo

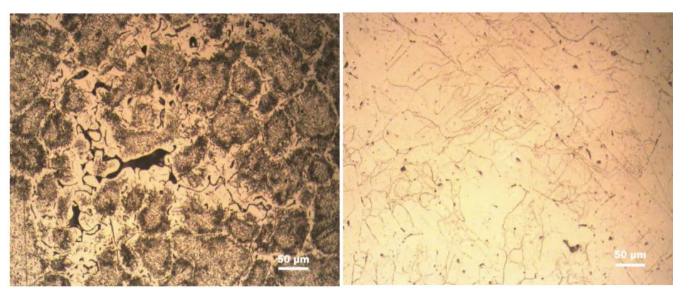

4.1 Umaleko wokwahlula-hlula ongqindilili we-6mm ubonakala kumphezulu wokukhulisa intonga yokuphosa. Ukwahlula yi-eutectic ephantsi-enyibilikayo, ebangelwa ukupholisa ngaphantsi kokuphosa. Ukubonakala kwe-macroscopic kumhlophe kwaye kucwebezelayo, kwaye umda onematrix ucacile;

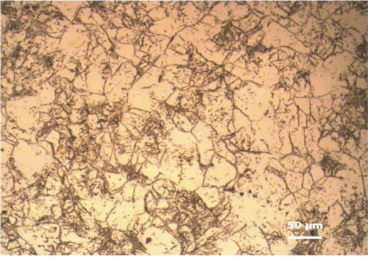

4.2 Ukwandiswa okuphezulu kubonisa ukuba kukho iipores kwi-edge ye-casting rod, ebonisa ukuba amandla okupholisa aphezulu kakhulu kwaye ulwelo lwe-aluminium alondli ngokwaneleyo. Kwi-interface phakathi koluhlu lokwahlula kunye ne-matrix, isigaba sesibini sinqabile kakhulu kwaye siyayeka, esiyindawo ehluphekileyo ye-solute. Ububanzi bentonga yokuphosa yi-1/2 Ubukho be-dendrites kwindawo kunye nokusabalalisa okungafaniyo kwamacandelo kubonisa ngakumbi ukuhlukana komgangatho ophezulu kunye neemeko zokukhula kwesikhokelo se-dendrites;

4.3 Ifoto yesiphene esinqamlezileyo kwindawo ye-200x yokujonga i-electron microscope scan ibonisa ukuba umphezulu urhabaxa apho ulusu luxobuka khona, kwaye umphezulu ugudile apho ulusu lungaxobukiyo. Emva kohlalutyo lokubunjwa kwe-EDS, iingongoma ze-1, i-2, i-3, kunye ne-6 ziindawo zesiphako, kwaye ukubunjwa kuqulethe i-C1, i-K, kunye ne-Na zizinto ezintathu, ezibonisa ukuba kukho icandelo le-ejenti yokucoca ekubunjweni;

4.4 Amacandelo e-C kunye ne-0 kumacandelo kumanqaku e-1, i-2, kunye ne-6 aphezulu, kwaye i-Mg, i-Si, i-Cu, kunye ne-Fe kwi-point 2 iphezulu kakhulu kunezo kumanqaku e-1 kunye ne-6, ebonisa ukuba ukubunjwa kwendawo yesiphene ayilingani kwaye kukho ukungcola komhlaba okubandakanyekayo;

4.5 Uhlalutyo lwamacandelo luqhutywe kumanqaku e-2 kunye ne-3 kwaye lwafumanisa ukuba amacandelo aqulethwe yi-Ca element, ebonisa ukuba i-talcum powder ingaba ibandakanyeka kumphezulu wentonga ye-aluminium ngexesha lenkqubo yokuphosa.

5 Isishwankathelo

Emva kokuhlalutya oku ngasentla, kunokubonwa ukuba ngenxa yobukho bokwahlula, i-arhente yokucoca, i-talcum powder kunye ne-slag inclusions ebusweni bentonga ye-aluminium, ukubunjwa akulingani, kwaye ulusu lufakwe kwi-mold cavity ngexesha lokukhupha, kubangela i-peeling defect entloko. Ngokunciphisa ubushushu bentonga yokuphosa kunye nokuqina kobunzima obuseleyo, iingxaki ze-peelling kunye nokutyumza zingancitshiswa okanye zisonjululwe; elona nyathelo lisebenzayo kukongeza umatshini wokuxobula kunye nokukhupha.

Ihlelwe nguMay Jiang esuka kwiMAT Aluminium

Ixesha lokuposa: Jun-12-2024