1. Intshayelelo

Ukukhanya kwemoto kwaqala kumazwe athuthukileyo kwaye ekuqaleni kwakukhokelwa zizigebenga zemoto zemveli. Ngophuhliso oluqhubekayo, lufumene umfutho obalulekileyo. Ukususela kwixesha amaIndiya aqala asebenzisa ialloyi ye-aluminium ukuvelisa iicrankshafts zeemoto ukuya kwimveliso yokuqala ye-Audi yeemoto ze-aluminiyam ngo-1999, i-alloy ye-aluminiyam ibone ukukhula okuqinileyo kwizicelo zeemoto ngenxa yeenzuzo zayo ezifana noxinano oluphantsi, amandla athile aphezulu kunye nokuqina, ukuqina okulungileyo kunye nokunyanzeliswa kwempembelelo, ukunyanzeliswa kwempembelelo ephezulu, ukunyanzeliswa kwempembelelo kunye nokuxhatshazwa kwempembelelo. Ngo-2015, inxalenye yesicelo se-aluminium alloy kwiimoto sele idlulile kwi-35%.

Ukukhanya kweemoto zaseTshayina kwaqala ngaphantsi kweminyaka eli-10 eyadlulayo, kwaye zombini itekhnoloji kunye nenqanaba lesicelo zisalela emva kwamazwe aphuhlileyo anjengeJamani, iUnited States kunye neJapan. Nangona kunjalo, ngokuphuhliswa kwezithuthi zamandla amatsha, ukukhanya kwezinto eziphathekayo kuqhubeka ngokukhawuleza. Isebenzisa ukunyuka kwezithuthi zamandla amatsha, itekhnoloji yokukhanya kwemoto yaseTshayina ibonisa umkhwa wokubamba amazwe aphuhlileyo.

Imarike yempahla ekhaphukhaphu yaseTshayina inkulu. Kwelinye icala, xa kuthelekiswa namazwe aphuhlileyo phesheya, itekhnoloji yokukhanya eTshayina yaqala kade, kwaye ubunzima besithuthi bubonke bukhulu. Ukuthathela ingqalelo umlinganiselo wezinto ezikhaphukhaphu kumazwe angaphandle, kusekho indawo eyaneleyo yophuhliso eTshayina. Kwelinye icala, iqhutywa yimigaqo-nkqubo, uphuhliso olukhawulezayo lweshishini elitsha leenqwelo zamandla eTshayina luya kukhulisa imfuno yezixhobo ezikhaphukhaphu kwaye lukhuthaze iinkampani zeemoto ukuba zihambe ziye kubunzima bokukhanya.

Ukuphuculwa kokukhutshwa kunye nemigangatho yokusetyenziswa kwamafutha kukunyanzelisa ukukhawuleziswa kokukhanya kwemoto. I-China iphumeze ngokupheleleyo imigangatho yokukhutshwa kwe-China ye-VI kwi-2020. Ngokwe "Indlela yoVavanyo kunye neZibonakalisi zokuTyelwa kweFuel yeeMoto zaBakhweli" kunye ne "Ukugcinwa kwamandla kunye neNew Energy Vehicle Technology Roadmap," i-5.0 L / km yomgangatho wokusetyenziswa kwamafutha. Ukuthathela ingqalelo indawo enyiniweyo yempumelelo enkulu kwitekhnoloji ye-injini kunye nokuncitshiswa kokukhutshwa kwezinto ezikhutshwayo, ukwamkela imilinganiselo yezixhobo zemoto ezikhaphukhaphu kunokunciphisa ngokufanelekileyo ukukhutshwa kwezithuthi kunye nokusetyenziswa kwamafutha. Ukukhanya kwezithuthi ezitsha zamandla kuye kwaba yindlela ebalulekileyo kuphuhliso lweshishini.

Kwi-2016, i-China Automotive Engineering Society ikhuphe "i-Energy Saving kunye neNew Energy Vehicle Technology Roadmap," eyayicwangcisa izinto ezifana nokusetyenziswa kwamandla, ukuhamba ngenqanawa, kunye nezixhobo zokuvelisa izithuthi zamandla amatsha ukusuka kwi-2020 ukuya kwi-2030. Ukukhanya okukhanyayo kuya kuba yikhokelo ephambili yophuhliso lwexesha elizayo lwezithuthi zamandla amatsha. Ukukhanya okukhanyayo kunokunyusa uluhlu lokuhamba kunye nokujongana "noluhlu lwamaxhala" kwiimoto zamandla amatsha. Ngokunyuka kwemfuno yoluhlu lokuhamba ngenqanawa, ukukhanya kweemoto kuya kungxamiseka, kwaye ukuthengiswa kweemoto zamandla amatsha kukhule kakhulu kwiminyaka yakutshanje. Ngokweemfuno zenkqubo yamanqaku kunye ne "Mid-to-Long-Term Development Plan for the Automotive Industry," kuqikelelwa ukuba ngo-2025, ukuthengiswa kwe-China yezithuthi zamandla amatsha kuya kudlula i-6 yezigidi zeeyunithi, kunye nezinga lokukhula ngonyaka elingaphezulu kwe-38%.

2.Iimpawu zeAluminiyam yeAluminiyam kunye nezicelo

2.1 Iimpawu zeAluminiyam yeAluminiyam

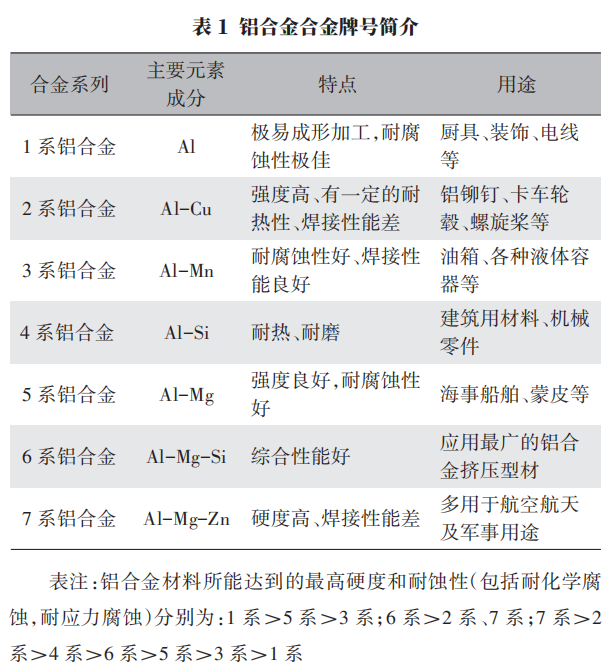

Ubuninzi be-aluminiyam sisinye kwisithathu sentsimbi, nto leyo eyenza kube lula. Inamandla athile aphezulu, isakhono esilungileyo sokukhupha, ukuxhathisa okuqinileyo kwi-corrosion, kunye nokuphinda kusetyenziswe okuphezulu. I-alloys ye-aluminiyam ibonakaliswe ngokuyinhloko yenziwe yi-magnesium, ibonisa ukuxhathisa ubushushu obuhle, iipropati ezilungileyo ze-welding, amandla amahle okudinwa, ukungakwazi ukomelezwa ngonyango lobushushu, kunye nokukwazi ukwandisa amandla ngokusebenza okubandayo. Uluhlu lwe-6 lubonakaliswe ngokuyinhloko luqulunqwe nge-magnesium kunye ne-silicon, kunye ne-Mg2Si njengesona sigaba sokuqinisa. Ii-alloys ezisetyenziswa kakhulu kolu luhlu ziyi-6063, 6061, kunye ne-6005A. Ipleyiti ye-aluminiyam ye-5052 yipleyiti ye-al-Mg ye-alloy yealluminiyam, ene-magnesium njengeyona nto idibanisayo. Yeyona isetyenziswa kakhulu i-anti-rust aluminium alloy. Le ngxubevange inamandla amakhulu, amandla aphezulu okudinwa, iplastiki elungileyo kunye nokumelana nokugqwala, ayinakomelezwa ngonyango lobushushu, ineplastikhi elungileyo kumsebenzi wokuqina obandayo, iplastiki ephantsi kumsebenzi obandayo wokuqina, ukuxhathisa okulungileyo kokugqwala, kunye neempawu ezilungileyo ze-welding. Isetyenziswa ikakhulu kumacandelo afana neepaneli ezisecaleni, izigqubuthelo zophahla, kunye neengcango zeengcango. I-6063 i-aluminium alloy yi-alloy yokuqinisa ukufudumala kwi-AL-Mg-Si series, kunye ne-magnesium kunye ne-silicon njengezinto eziphambili zokudibanisa. Yiprofayili yokuqinisa i-aluminium eyomelezwa ngokufudumeza ngamandla aphakathi, ngokukodwa isetyenziswe kumacandelo esakhiwo njengamakholomu kunye neepaneli zecala ukuze zithwale amandla. Intshayelelo ngamabakala e-aluminiyam alloy iboniswe kwiThebhile 1.

2.2 I-Extrusion yindlela eBalulekileyo yokwenza iAluminiyam iAluminiyam

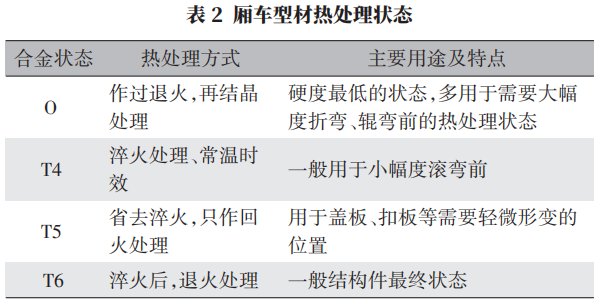

I-Aluminiyam i-alloy extrusion yindlela yokwenza ishushu, kwaye yonke inkqubo yokuvelisa ibandakanya ukwenza i-aluminium alloy phantsi koxinzelelo lweendlela ezintathu. Yonke inkqubo yemveliso inokuchazwa ngolu hlobo lulandelayo: a. I-aluminium kunye nezinye i-alloys ziyancibilika kwaye zifakwe kwiibhilidi ezifunekayo ze-aluminium alloy; b. Iibhilidi ezifudunyeziweyo zifakwe kwisixhobo sokukhupha i-extrusion. Ngaphantsi kwesenzo se-cylinder ephambili, i-aluminium alloy billet yenziwe kwiiprofayili ezifunekayo ngokusebenzisa i-cavity ye-mold; c. Ukuze kuphuculwe iipropathi zemishini yeeprofayili ze-aluminium, unyango lwesisombululo luqhutywa ngexesha okanye emva kwe-extrusion, elandelwa kunyango lokuguga. Iimpawu zomatshini emva kokunyanga ukuguga ziyahluka ngokwezinto ezahlukeneyo kunye nolawulo lokuguga. Ubume bonyango lobushushu bohlobo lweeprofayili zelori luboniswe kwiThebhile yesi-2.

Iimveliso zeAluminiyam ezikhutshiweyo zineenzuzo ezininzi kunezinye iindlela zokwenza:

a. Ngexesha lokukhupha, intsimbi ekhutshiweyo ifumana amandla kwaye ifanayo yoxinzelelo lwendlela-ntathu yoxinzelelo kwindawo ye-deformation kunokuqengqeleka kunye ne-forging, ngoko inokudlala ngokupheleleyo iplastiki yesinyithi esetyenzisiweyo. Ingasetyenziselwa ukucubungula iintsimbi ezinzima-ukukhubaza ezingenako ukusetyenzwa ngokuqengqeleka okanye ukubunjwa kwaye ingasetyenziselwa ukwenza amacandelo ahlukeneyo anzima okanye aqinileyo anqamlezayo.

b. Ngenxa yokuba i-geometry yeeprofayili ze-aluminium inokuhluka, amacandelo abo anokuqina okuphezulu, okunokuphucula ukuqina komzimba wesithuthi, ukunciphisa iimpawu zayo ze-NVH, kunye nokuphucula iimpawu zokulawula izithuthi.

c. Iimveliso ezinobuchule bokukhupha, emva kokucima kunye nokuguga, zinamandla amakhulu kakhulu e-longitudinal (R, Raz) kuneemveliso ezicutshungulwa ngezinye iindlela.

d. Umphezulu weemveliso emva kwe-extrusion inombala omhle kunye nokuxhathisa okulungileyo kokuhlwa, ukuphelisa imfuno yolunye unyango oluchasene ne-corrosion surface.

e. Ukusetyenzwa kwe-Extrusion kunokuguquguquka okukhulu, izixhobo eziphantsi kunye neendleko zokubumba, kunye neendleko eziphantsi zokutshintsha koyilo.

f. Ngenxa yokulawulwa kweprofayili ye-aluminium ye-cross-sections, i-degree of component integration inokwandiswa, inani lamacandelo lingancitshiswa, kunye noyilo lwamacandelo ahlukeneyo lunokufikelela kwi-welding positioning echanekileyo.

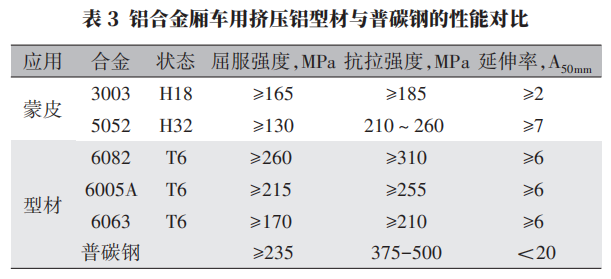

Ukuthelekisa ukusebenza phakathi kweeprofayili ze-aluminium ezikhutshiweyo kwiilori zohlobo lwebhokisi kunye nentsimbi yekhabhoni ecacileyo iboniswe kwiThebhile 3.

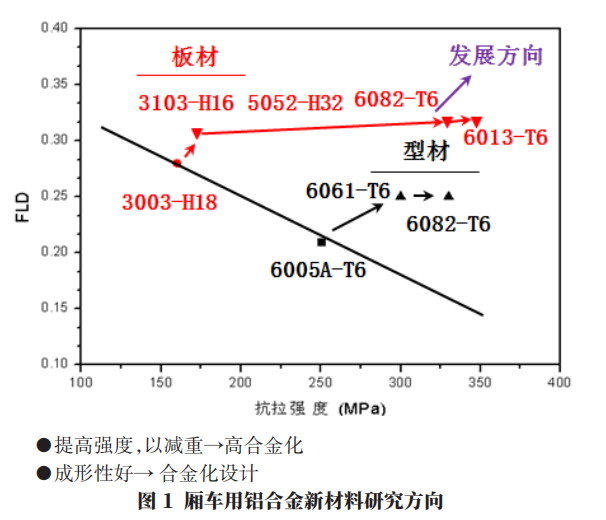

Ulwalathiso olulandelayo loPhuhliso lweeProfayili zeAluminiyam yeAluminiyam kwiiLori zohlobo lweBhokisi: Ukuphucula ngakumbi amandla eprofayili kunye nokuphucula ukusebenza kwe-extrusion. Isikhokelo sophando sezinto ezintsha zeeprofayili ze-aluminium alloy kwiilori zohlobo lwebhokisi luboniswe kuMfanekiso 1.

I-3.I-Aluminium Alloy Box Isakhiwo seLori, uHlahlelo lwaMandla, kunye noQinisekiso

3.1 Ulwakhiwo lwelori yeAluminiyam yeBhokisi yeAluminiyam

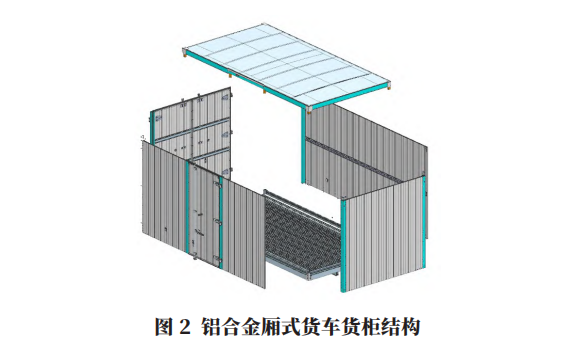

Ibhokisi yebhokisi yelori iqulathe ubukhulu becala indibano panel panel, ekhohlo nasekunene indibano panel kwicala lasekunene, ngasemva ucango icala panel assembly, indibano umgangatho, indibano uphahla, kunye neebholiti U-ezimile, abalindi ecaleni, abalindi ngasemva, iiflaphu zodaka, kunye nezinye izincedisi ezidityaniswe kwi-chassis yeklasi yesibini. Ibhokisi lomzimba webhokisi imiqadi, iintsika, iiplanga ezisecaleni, kunye neepaneli zomnyango zenziwe nge-aluminium alloy extruded profiles, ngelixa umgangatho kunye neepaneli zephahla zenziwe nge-5052 aluminium alloy flat plates. Ubume belori yebhokisi ye-aluminium ye-alloy iboniswe kuMfanekiso 2.

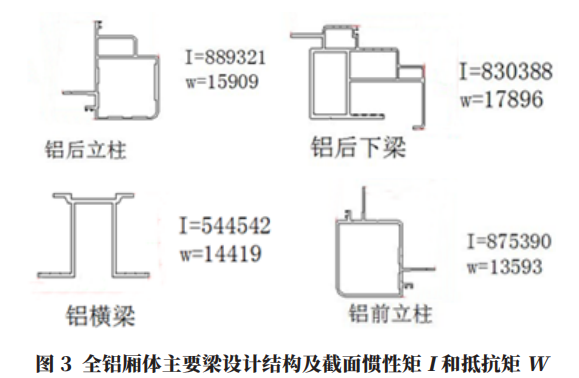

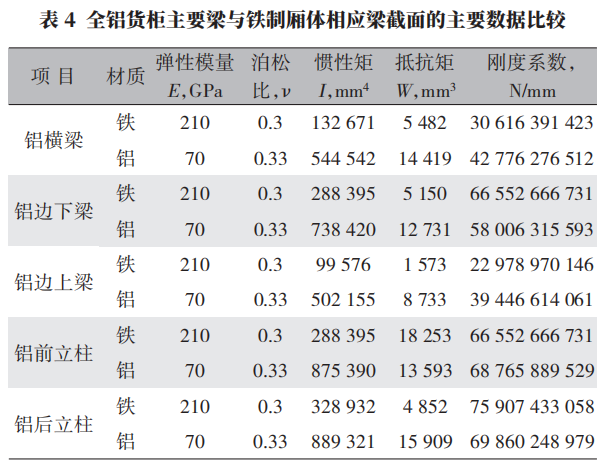

Ukusebenzisa inkqubo ye-extrusion eshushu ye-6 ye-aluminium i-alloy ye-alloy inokwenza i-cross-sections enzima, uyilo lweeprofayili ze-aluminium ezinamacandelwana anzima anokugcina izinto eziphathekayo, ukuhlangabezana neemfuno zamandla emveliso kunye nokuqina, kunye nokuhlangabezana neemfuno zokunxibelelana phakathi kwamacandelo ahlukeneyo. Ngoko ke, isakhiwo esiphambili soyilo lwe-boam kunye namaxesha amacandelo e-inertia I kunye namaxesha okuchasa W aboniswe kwi-Figure 3.

Ukuthelekiswa kwedatha ephambili kwiThebhile 4 ibonisa ukuba amaxesha amacandelo e-inertia kunye nezihlandlo ezichasayo zeprofayili ye-aluminium eyenziweyo ingcono kunedatha ehambelanayo yeprofayili yentsimbi eyenziwe ngentsimbi. Idatha ye-coefficient yokuqina iphantse ifane naleyo yeprofayili yentsimbi eyenziwe ngentsimbi ehambelanayo, kwaye zonke ziyahlangabezana neemfuno zokuguqulwa.

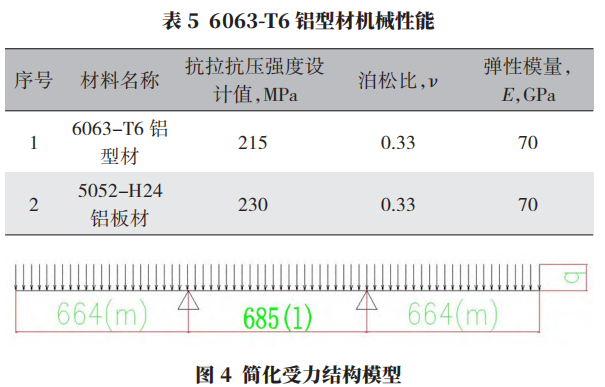

3.2 UBalo loxinzelelo olukhulu

Ukuthatha icandelo eliphambili lomthwalo, i-crossbeam, njengento, uxinzelelo oluphezulu lubalwa. Umthwalo olinganisiweyo ngu-1.5 t, kwaye i-crossbeam yenziwe nge-6063-T6 iprofayili ye-aluminium alloy eneempawu zomatshini njengoko kuboniswe kwiThebhile 5. I-beam yenziwe lula njengesakhiwo se-cantilever sokubala amandla, njengoko kuboniswe kwi-Figure 4.

Ukuthatha i-344mm ye-span beam, umthwalo ocinezelayo kwi-beam ubalwa njenge-F = 3757 N esekelwe kwi-4.5t, ephindwe kathathu kumthwalo oqhelekileyo we-static. q=F/L

apho q kuxinzelelo lwangaphakathi lomqadi phantsi komthwalo, N / mm; I-F ngumthwalo owenziwe ngumqadi, ubalwa ngokusekelwe kumaxesha angama-3 umthwalo osemgangathweni osemgangathweni, ongu-4.5 t; L bubude bomqadi, mm.

Ngoko ke, uxinzelelo lwangaphakathi q lu:

Ifomula yokubala uxinzelelo imi ngolu hlobo lulandelayo:

Owona mzuzu uphezulu ngulo:

Ukuthatha ixabiso elipheleleyo lomzuzu, M=274283 N·mm, uxinzelelo olukhulu σ=M/(1.05×w)=18.78 MPa, kunye nexabiso eliphezulu loxinzelelo σ<215 MPa, elihlangabezana neemfuno.

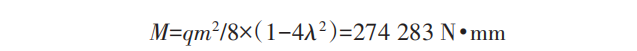

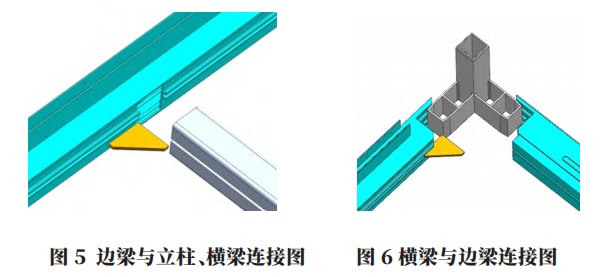

3.3 Iimpawu zoQhagamshelwano lwaMalunga ahlukeneyo

I-alloy ye-aluminium ineempawu ze-welding ezimbi, kwaye amandla ayo e-welding point yi-60% kuphela yamandla ezinto ezisisiseko. Ngenxa yokugqunywa koluhlu lwe-Al2O3 kwi-aluminium alloy surface, i-melting point ye-Al2O3 iphezulu, ngelixa i-melting point ye-aluminium iphantsi. Xa i-alloy ye-aluminium idityanisiwe, i-Al2O3 kumphezulu kufuneka iphulwe ngokukhawuleza ukwenza i-welding. Ngelo xesha, intsalela ye-Al2O3 iya kuhlala kwisisombululo se-aluminium alloy, echaphazela isakhiwo se-aluminium alloy kunye nokunciphisa amandla e-aluminium alloy welding point. Ngoko ke, xa uyila isitya se-aluminium yonke, ezi mpawu ziqwalaselwa ngokupheleleyo. I-Welding yindlela ephambili yokumisa, kwaye iindawo eziphambili zokuthwala umthwalo zixhunywe ngeebholiti. Uqhagamshelwano olufana ne-riveting kunye nesakhiwo se-dovetail siboniswe kwiMifanekiso 5 kunye ne-6.

Isakhiwo esiphambili somzimba webhokisi ye-aluminiyam yonke ithatha isakhiwo esineentsimbi ezithe tye, iintsika ezithe nkqo, iiplanga ezisecaleni, kunye nemiphetho edibeneyo edibeneyo. Kukho iindawo zokudibanisa ezine phakathi komqadi othe tye kunye nentsika ethe nkqo. Amanqaku okudibanisa afakwe kwi-serrated gaskets kwi-mesh kunye nomda odibeneyo we-horizontal beam, ukuthintela ngokufanelekileyo ukutyibilika. Amanqaku asibhozo eembombo adityaniswe ngokukodwa ngokufakela intsimbi engundoqo, elungiswe ngeebholiti kunye ne-rivets yokuzivalela, kwaye zomelezwe ngamacwecwe e-aluminium angama-5mm angama-triangular adityaniswe ngaphakathi kwebhokisi ukuqinisa izikhundla zekona ngaphakathi. Imbonakalo yangaphandle yebhokisi ayinayo i-welding okanye iindawo zokudibanisa eziveziweyo, eziqinisekisa ukubonakala kwebhokisi.

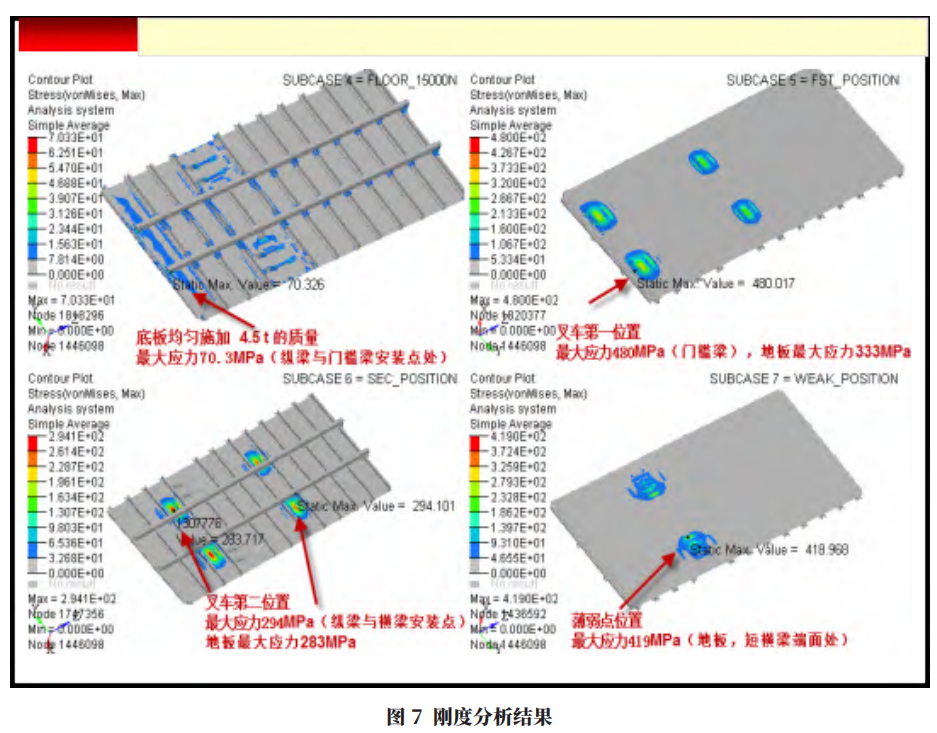

3.4 SE IThekhnoloji yobuNjineli be-synchronous

Itekhnoloji yobunjineli ye-SE isetyenziselwa ukusombulula iingxaki ezibangelwa kukunxaxha kobungakanani obukhulu obuqokelelweyo kumacandelo ahambelanayo kumzimba webhokisi kunye nobunzima bokufumana oonobangela bezithuba kunye nokungaphumeleli kokutya. Ngokusebenzisa uhlalutyo lwe-CAE (jonga i-Figure 7-8), uhlalutyo lokuthelekisa luqhutywa kunye nemizimba yebhokisi yentsimbi ukuze kuhlolwe amandla onke kunye nokuqina kwebhokisi lebhokisi, ukufumana amanqaku abuthathaka, kwaye uthathe amanyathelo okuphucula nokuphucula inkqubo yoyilo ngokufanelekileyo.

4.Lightweighting Effect of Aluminium Alloy Box Truck

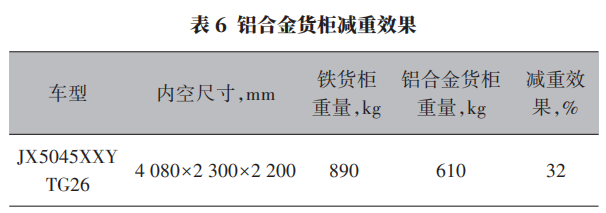

Ukongeza kumzimba webhokisi, ii-alloys ze-aluminium zingasetyenziselwa ukutshintsha intsimbi kumacandelo ahlukeneyo eebhokisi zelori, ezifana ne-mudguards, i-back guards, i-side guards, i-latches yocango, i-hinges yeminyango, kunye nemiphetho ye-apron yangasemva, ukufezekisa ukunciphisa ubunzima be-30% ukuya kwi-40% yendawo yempahla. Isiphumo sokunciphisa ubunzima kwisitya esingenanto se-4080mm×2300mm×2200mm sempahla siboniswe kwiThebhile 6. Oku kusombulula ngokusisiseko iingxaki zobunzima obugqithisileyo, ukungathotyelwa kwezaziso, kunye nemingcipheko yokulawula iikhompathi zempahla zentsimbi zemveli ezenziwe ngentsimbi.

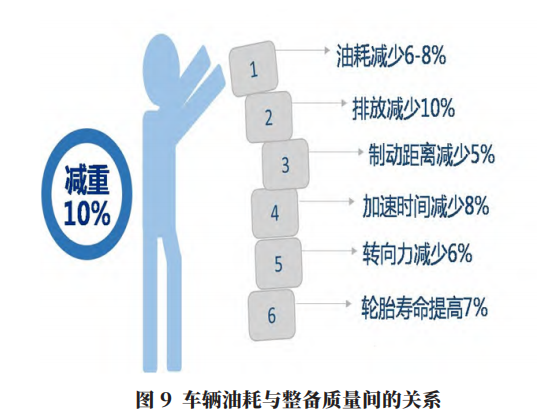

Ngokutshintsha intsimbi yesiko ngealloyi ye-aluminiyam kumacandelo emoto, ayipheleli nje ekufezekiseni iziphumo ezigqwesileyo zokukhanya, kodwa inokuba negalelo ekongeni amafutha, ukucutha ukukhutshwa, kunye nokuphuculwa kokusebenza kwesithuthi. Okwangoku, kukho iimbono ezahlukeneyo malunga negalelo le-lightweight ekongeni amafutha. Iziphumo zophando lwe-International Aluminium Institute ziboniswa kuMfanekiso 9. Yonke i-10% yokunciphisa ubunzima besithuthi inokunciphisa ukusetyenziswa kwamafutha nge-6% ukuya kwi-8%. Ngokusekelwe kwizibalo zasekhaya, ukunciphisa ubunzima bemoto nganye yabahambi nge-100 kg kunokunciphisa ukusetyenziswa kwamafutha nge-0.4 L / 100 km. Igalelo lokunciphisa umbane ekongeni amafutha lisekelwe kwiziphumo ezifunyenwe kwiindlela ezahlukeneyo zophando, ngoko kukho ukuhluka. Nangona kunjalo, ukukhanya kweemoto kunempembelelo enkulu ekunciphiseni ukusetyenziswa kwamafutha.

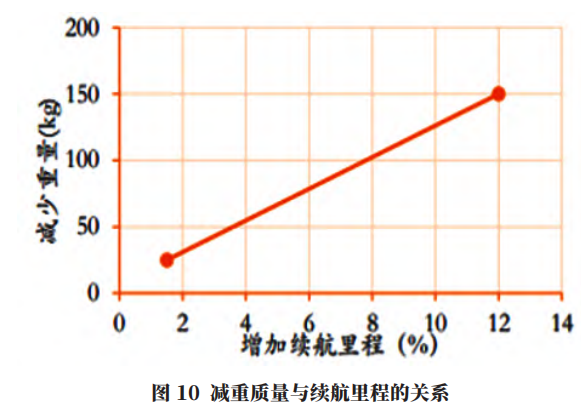

Kwizithuthi zombane, umphumo wokukhanya ubonakala ngakumbi. Okwangoku, ubuninzi bamandla eyunithi yeebhetri zamandla ezithuthi zombane zahluke kakhulu kuleyo yezithuthi zamafutha ezilulwelo eziqhelekileyo. Ubunzima benkqubo yamandla (kubandakanywa nebhetri) yezithuthi zombane zihlala zithatha i-20% ukuya kwi-30% yobunzima bezithuthi zizonke. Kwangaxeshanye, ukophula ukusebenza kweebhetri ngumngeni kwihlabathi liphela. Ngaphambi kokuba kubekho impumelelo enkulu kwitekhnoloji yebhetri esebenza kakhulu, ukukhanya kuyindlela esebenzayo yokuphucula uluhlu lokuhamba ngeenqwelo zombane. Ngayo yonke i-100 kg yokunciphisa ubunzima, uluhlu lokuhamba ngeenqwelo zombane lunokunyuswa nge-6% ukuya kwi-11% (ubudlelwane phakathi kokunciphisa ubunzima kunye noluhlu lokuhamba luboniswe kuMfanekiso 10). Okwangoku, uluhlu oluhambayo lweenqwelo zombane ezicocekileyo alukwazi ukuhlangabezana neemfuno zabantu abaninzi, kodwa ukunciphisa ubunzima ngomlinganiselo othile kunokuphucula kakhulu uluhlu lokuhamba, ukunciphisa ukuxhalaba koluhlu kunye nokuphucula amava omsebenzisi.

5.Isiphelo

Ukongeza kwisakhiwo se-aluminiyam ye-aluminium yebhokisi yebhokisi ye-aluminium efakwe kweli nqaku, kukho iintlobo ezahlukeneyo zeelori zebhokisi, ezifana neepaneli ze-honeycomb, i-aluminium buckle plates, iifreyimu ze-aluminium + izikhumba ze-aluminium, kunye nezikhongozeli ze-iron-aluminium hybrid cargo. Zinenzuzo yobunzima bokukhanya, amandla athile aphezulu, kunye nokuchasana kakuhle kwe-corrosion, kwaye ayifuni ipeyinti ye-electrophoretic yokukhusela i-corrosion, ukunciphisa impembelelo yokusingqongileyo yepeyinti ye-electrophoretic. Ilori yebhokisi ye-aluminiyam ixazulula ngokusisiseko iingxaki zobunzima obugqithisileyo, ukungathotyelwa kwezaziso, kunye nobungozi bokulawulwa kweendawo zempahla zentsimbi ezenziwe ngentsimbi.

I-Extrusion yindlela ebalulekileyo yokucubungula i-alloys ye-aluminium, kunye neeprofayili ze-aluminium zinempahla egqwesileyo yomatshini, ngoko ke ukuqina kwecandelo kuphezulu kakhulu. Ngenxa yecandelo eliguquguqukayo le-cross-section, i-alloys ye-aluminium inokufezekisa ukudibanisa kwemisebenzi yamacandelo amaninzi, okwenza kube yinto efanelekileyo yokukhanya kwemoto. Nangona kunjalo, ukusetyenziswa okubanzi kwee-alloys ze-aluminium kujongene nemingeni efana nokungonelanga kwesakhono se-aluminium alloy cargo compartments, imiba yokwenza kunye ne-welding, kunye neendleko eziphezulu zophuhliso kunye nokukhuthaza iimveliso ezintsha. Esona sizathu sisesokuba ialluminiyam ialloy ixabisa ngaphezulu kunentsimbi phambi kokuba i-ecology yokurisayikilisha yealloys ye-aluminiyam ikhule.

Ukuqukumbela, umda wokusetyenziswa kweealluminiyamu kwiimoto uya kuba banzi, kwaye ukusetyenziswa kwazo kuya kuqhubeka ukwanda. Kwimikhwa yangoku yokonga amandla, ukunciphisa ukukhutshwa, kunye nophuhliso lweshishini elitsha lezithuthi zamandla, kunye nokuqonda okunzulu kweempawu ze-aluminium alloy kunye nezisombululo ezisebenzayo kwiingxaki zesicelo se-aluminium, izixhobo ze-aluminium extrusion ziya kusetyenziswa ngokubanzi kwi-automotive lightweighting.

Ihlelwe nguMay Jiang esuka kwiMAT Aluminium

Ixesha lokuposa: Jan-12-2024