Isizathu sokuba iiprofayili ze-aluminium alloy zisetyenziswa kakhulu ebomini kunye nemveliso kukuba wonke umntu uyaziqonda ngokupheleleyo iingenelo zayo ezinje ngoxinaniso oluphantsi, ukuchasana nokugqwala, ukuhanjiswa kombane okugqwesileyo, iipropathi ezingeyo-ferromagnetic, ukubumba, kunye nokuphinda kusetyenziswe.

Umzi-mveliso waseTshayina we-aluminiyam ukhule ukusuka ekuqaleni, ukusuka kwincinci ukuya enkulu, de ibe lilizwe elikhulu lokuvelisa iprofayile ye-aluminium, kunye nenqanaba lemveliso kuqala emhlabeni. Nangona kunjalo, njengoko iimfuno zeemarike zeemveliso zeprofayili ze-aluminium ziqhubeka zikhula, ukuveliswa kweeprofayili ze-aluminium kuye kwaphuhliswa kwicala lobunzima, ukuchaneka okuphezulu, kunye nokuveliswa kwemveliso enkulu, okuye kwazisa uluhlu lweengxaki zemveliso.

Iiprofayili zeAluminiyam ziveliswa kakhulu yi-extrusion. Ngexesha lokuvelisa, ngaphezu kokuqwalasela ukusebenza kwe-extruder, ukuyila kwesikhunta, ukubunjwa kwentonga ye-aluminium, unyango lobushushu kunye nezinye izinto zenkqubo, i-cross-sectional design of profile kufuneka iqwalaselwe. Uyilo olugqwesileyo lweprofayili alunakunciphisa kuphela ubunzima benkqubo ukusuka kumthombo, kodwa nokuphucula umgangatho kunye nokusetyenziswa kwesiphumo semveliso, ukunciphisa iindleko kunye nokunciphisa ixesha lokuhambisa.

Eli nqaku lishwankathela iindlela ezininzi ezisetyenziswa ngokuqhelekileyo kwiprofayili ye-aluminium yeprofayili yoyilo olunqamlezileyo ngeemeko zokwenyani kwimveliso.

1. Imigaqo yoyilo lwecandelo leprofayili yeAluminiyam

I-Aluminiyam iprofayili ye-extrusion yindlela yokucubungula apho intonga ye-aluminium evuthayo ilayishwe kwi-barrel ye-extrusion, kwaye uxinzelelo lufakwe kwi-extruder ukuyikhupha kwi-fae hole yesimo esinikiweyo kunye nobukhulu, okubangela ukuguqulwa kweplastiki ukufumana imveliso efunekayo. Ekubeni intonga ye-aluminiyam ichatshazelwa yizinto ezahlukeneyo ezifana nobushushu, isantya se-extrusion, isixa se-deformation, kunye ne-mold ngexesha lenkqubo yokuguqulwa, ukufana kokuhamba kwesinyithi kunzima ukulawula, okuzisa ubunzima obuthile bokuyila ukubumba. Ukuze kuqinisekiswe amandla okubumba kwaye ugweme ukuqhekeka, ukuwa, ukutshiza, njl., oku kulandelayo kufuneka kuphetshwe kuyilo lwecandelo leprofayili: i-cantilevers enkulu, izivulo ezincinci, imingxuma encinci, i-porous, i-asymmetrical, i-thick-walled, ubukhulu bodonga olungalinganiyo, njl. Ngenxa yokuba xa abaqulunqi bengenalo ulwazi lwenkqubo ye-extrusion kwaye abayiqondi izixhobo zenkqubo efanelekileyo, kwaye iimfuno zenkqubo yokuvelisa ziphezulu kakhulu kwaye zingqongqo, izinga lokufaneleka liya kuncitshiswa, ixabiso liya kwanda, kwaye iphrofayili efanelekileyo ayiyi kuveliswa. Ngoko ke, umgaqo woyilo lwecandelo leprofayili ye-aluminium kukusebenzisa inkqubo elula kangangoko kunokwenzeka ngelixa usanelisa uyilo lwayo olusebenzayo.

2. Ezinye iingcebiso malunga noyilo lojongano lweprofayili ye-aluminium

2.1 Imbuyekezo yempazamo

Ukuvala enye yeziphene eziqhelekileyo kwimveliso yeprofayili. Ezona zizathu ziphambili zezi zilandelayo:

(1) Iiprofayili ezineengcango ezinzulu ezinqamlezileyo ziya kuvala rhoqo xa zikhutshiwe.

(2) Ukolula kunye nokulungiswa kweeprofayili kuya kuqinisa ukuvala.

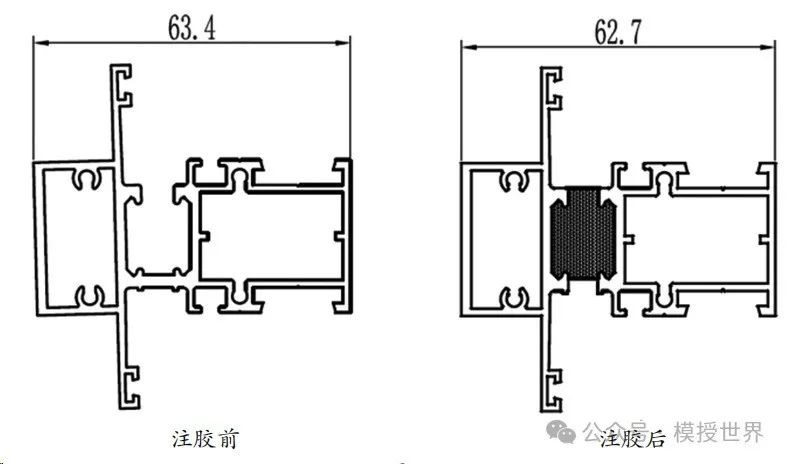

(3) Iiprofayili ezifakwe kwi-glue kunye nezakhiwo ezithile ziya kuba nokuvala ngenxa yokunciphisa i-colloid emva kokuba i-glue ifakwe.

Ukuba ukuvala okukhankanywe ngasentla akukona kubi, kunokuphetshwa ngokulawula izinga lokuhamba ngokuyila i-mold; kodwa ukuba izinto ezininzi zibekwe phezulu kwaye i-mold design kunye neenkqubo ezinxulumene nazo azikwazi ukusombulula ukuvala, imbuyekezo yangaphambili inokunikezelwa kuyilo lwecandelo elinqamlezayo, oko kukuthi, ukuvulwa kwangaphambili.

Isixa sembuyekezo yokuvula kwangaphambili kufuneka ikhethwe ngokusekelwe kwisakhiwo sayo esithile kunye namava okuvalwa kwangaphambili. Ngeli xesha, ukuyila komzobo wokuvula isikhunta (ukuvulwa kwangaphambili) kunye nomzobo ogqityiweyo uhlukile (Umfanekiso 1).

2.2 Yahlula amacandelo amakhulu abe ngamacandelo amancinci amaninzi

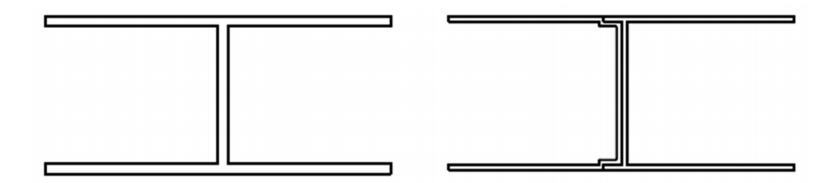

Ngokuphuhliswa kweeprofayili ezinkulu ze-aluminium, i-cross-sectional designs yeeprofayili ezininzi ziya ziba zikhulu kwaye zikhudlwana, oku kuthetha ukuba uchungechunge lwezixhobo ezifana ne-extruders ezinkulu, iimbumba ezinkulu, iintonga ezinkulu ze-aluminium, njl. Kwamanye amacandelo amakhulu anokuthi aphunyezwe ngokudibanisa, kufuneka ahlulwe abe ngamacandelo amancinci amancinci ngexesha loyilo. Oku akukwazi ukunciphisa iindleko kuphela, kodwa kwenza kube lula ukuqinisekisa ukuba i-flatness, i-curvature, kunye nokuchaneka (Umfanekiso 2).

2.3 Misela iimbambo zokuqinisa ukuphucula ukuthambeka kwayo

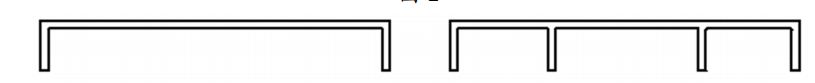

Iimfuno ze-flatness zihlala zidibana xa kuyilwa amacandelo eprofayili. Iiprofayili ezincinci ze-span zilula ukuqinisekisa ukunyanzeliswa ngenxa yamandla abo aphezulu. Iiprofayili zexesha elide ziya kuncipha ngenxa yomxhuzulane wazo nje emva kokukhutshwa, kwaye inxalenye enoxinzelelo olukhulu lokugoba embindini iya kuba yeyona concave. Kwakhona, ngenxa yokuba ipaneli yodonga inde, kulula ukuvelisa amaza, okuya kwenza kube mandundu ukuphumla kwenqwelomoya. Ke ngoko, ubungakanani obukhulu bezakhiwo zeepleyiti ezisicaba kufuneka ziphetshwe kuyilo lwamacandelo anqamlezayo. Ukuba kuyimfuneko, ukuqinisa iimbambo kunokufakwa phakathi ukuze kuphuculwe ukucaca kwayo. (Umfanekiso 3)

2.4 Inkqubo yesibini

Kwinkqubo yokuvelisa iprofayili, amanye amacandelo anzima ukugqiba ngokusetyenzwa kwe-extrusion. Nokuba inokwenziwa, iindleko zokusetyenzwa kunye nemveliso ziya kuba phezulu kakhulu. Ngeli xesha, ezinye iindlela zokucubungula zingaqwalaselwa.

I-Case 1: Imingxuma enobubanzi obungaphantsi kwe-4mm kwicandelo leprofayili iya kwenza ukuba isikhunta singonelanga ngamandla, sonakaliswe ngokulula, kwaye kunzima ukusetyenzwa. Kucetyiswa ukuba kususwe imingxunya emincinci kwaye usebenzise ukugaya endaweni yoko.

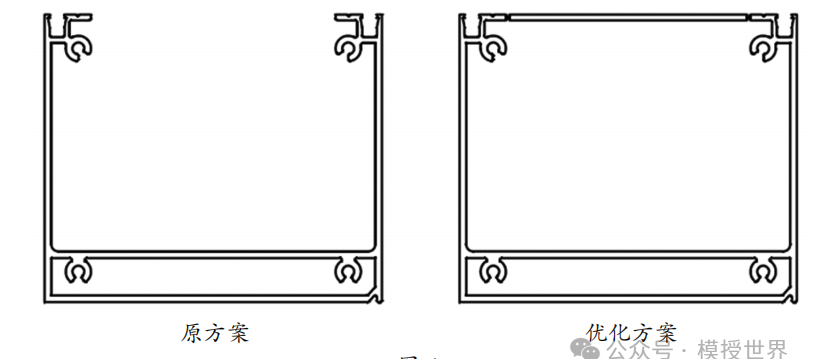

Imeko yesi-2: Ukuveliswa kwee-grooves eziqhelekileyo ezibunjwa ngu-U akukho nzima, kodwa ukuba ubunzulu be-groove kunye nobubanzi be-groove budlula i-100mm, okanye umlinganiselo wobubanzi be-groove ukuya kwi-groove ubunzulu abunangqiqo, iingxaki ezifana nokungonelanga kwamandla okubumba kunye nobunzima bokuqinisekisa ukuvulwa kuya kuhlangabezana nayo ngexesha lokuvelisa. Xa uyila icandelo leprofayili, ukuvulwa kunokuthathwa njengento evaliweyo, ukwenzela ukuba i-mold eqinile ye-original enamandla anganelanga ingaguqulwa ibe yimbumba ezinzileyo yokwahlukana, kwaye akuyi kubakho ingxaki yokuvula i-deformation ngexesha lokukhupha, okwenza kube lula ukuyigcina imilo. Ukongezelela, ezinye iinkcukacha zinokwenziwa ekudibaneni phakathi kweziphelo ezimbini zokuvula ngexesha loyilo. Umzekelo: setha amanqaku amise okwe-V, iigrooves ezincinci, njl., ukwenzela ukuba zisuswe ngokulula ngexesha lokwenziwa komatshini wokugqibela (Umfanekiso 4).

2.5 Intsonkothe ngaphandle kodwa ilula ngaphakathi

Iprofayili ye-Aluminiyam ye-extrusion molds inokwahlulwa ibe yi-molds eqinile kunye ne-shunt molds ngokokuba i-cross-section inomngxuma. Ukusetyenzwa kokungunda okuqinileyo kulula, ngelixa ukusetyenzwa kwe-shunt mold kubandakanya iinkqubo ezintsonkothileyo ezinje ngemingxuma kunye neentloko ezingundoqo. Ngoko ke, ingqwalasela epheleleyo kufuneka inikwe kuyilo lwecandelo leprofayili, oko kukuthi, i-contour yangaphandle yecandelo inokuqulunqwa ukuba ibe nzima ngakumbi, kunye ne-grooves, imingxuma ye-screw, njl. Ngale ndlela, zombini ukulungiswa kwesikhunta kunye nokugcinwa kuya kuba lula kakhulu, kwaye izinga lesivuno liya kuphuculwa.

2.6 Umda ogciniweyo

Emva kwe-extrusion, iiprofayili ze-aluminium zineendlela ezahlukeneyo zonyango zonyango ngokweemfuno zabathengi. Phakathi kwabo, iindlela ze-anodizing kunye ne-electrophoresis zinempembelelo encinci kubukhulu ngenxa yomgca wefilimu encinci. Ukuba indlela yonyango yomgangatho wepowder isetyenzisiweyo, i-powder iya kuqokelela ngokulula kwiikona kunye ne-grooves, kwaye ubukhulu boluhlu olulodwa bunokufikelela kwi-100 μm. Ukuba le yindawo yendibano, njengesilayidi, kuya kuthetha ukuba kukho iileya ezi-4 zokugquma isitshizi. Ukutyeba ukuya kuthi ga kwi-400 μm kuya kwenza ukuba indibano ingenzeki kwaye ichaphazele ukusetyenziswa.

Ukongezelela, njengoko inani le-extrusions linyuka kwaye i-mold inxiba, ubungakanani beeprofayili zeprofayili buya kuba buncinci kwaye buncinci, ngelixa ubukhulu be-slider buya kuba bukhulu kwaye bukhulu, okwenza indibano ibe nzima ngakumbi. Ngokusekelwe kwezi zizathu zingasentla, imida efanelekileyo kufuneka igcinwe ngokwemiqathango ethile ngexesha loyilo ukuqinisekisa ukudibanisa.

2.7 Ukumakishwa kokunyamezelana

Kuyilo lwecandelo elinqamlezileyo, umzobo wendibano uveliswa kuqala kwaye umzobo wemveliso yeprofayile uveliswa. Umzobo wendibano ochanekileyo awuthethi ukuba umzobo wemveliso yeprofayili ugqibelele. Abanye abaqulunqi bayayihoya ukubaluleka komlinganiselo kunye nokumakishwa kokunyamezela. Izikhundla eziphawulweyo ngokuqhelekileyo ziyimilinganiselo efuna ukuqinisekiswa, njengale: indawo yendibano, ukuvulwa, ubunzulu begroove, ububanzi begroove, njl., kwaye kulula ukulinganisa nokuhlola. Ukunyamezela i-dimensional dimensional, inqanaba lokuchaneka elihambelanayo linokukhethwa ngokomgangatho wesizwe. Eminye imilinganiselo yendibano ebalulekileyo kufuneka iphawulwe ngamaxabiso athile okunyamezelana kumzobo. Ukuba ukunyamezela kukhulu kakhulu, indibano iya kuba nzima ngakumbi, kwaye ukuba ukunyamezela kuncinci, iindleko zokuvelisa ziya kwanda. Uluhlu lonyamezelo olufanelekileyo lufuna ukuqokelelwa kwamava omyili wemihla ngemihla.

2.8 Uhlengahlengiso oluneenkcukacha

Iinkcukacha zigqiba impumelelo okanye ukungaphumeleli, kwaye kuyafana nakwiprofayili yoyilo lwecandelo elinqamlezayo. Utshintsho oluncinci alukwazi ukukhusela kuphela ukubunjwa kunye nokulawula izinga lokuhamba, kodwa nokuphucula umgangatho ophezulu kunye nokunyusa izinga lesivuno. Enye yeendlela ezisetyenziswa ngokuqhelekileyo ziikona ezijikelezayo. Iiprofayili ezongeziweyo azinakuba neekona ezibukhali ngokupheleleyo kuba iingcingo zobhedu ezibhityileyo ezisetyenziswa ekusikeni ucingo nazo zineedamitha. Nangona kunjalo, isantya sokuhamba kwiikona sicotha, ukungqubuzana kukhulu, kwaye uxinzelelo lugxininisekile, kukho iimeko apho iimpawu ze-extrusion zibonakala, ubungakanani bunzima ukulawula, kunye nokubunjwa kukulungele ukutshiza. Ngoko ke, i-radius ejikelezayo kufuneka inyuswe kangangoko kunokwenzeka ngaphandle kokuchaphazela ukusetyenziswa kwayo.

Nangona iveliswa ngumatshini omncinci we-extrusion, ubukhulu bodonga lweprofayili akufanele bube ngaphantsi kwe-0.8mm, kwaye ubukhulu bodonga lwecandelo ngalinye lecandelo akufanele buhluke ngamaxesha angaphezu kwama-4. Ngexesha loyilo, imigca yediagonal okanye i-arc transitions ingasetyenziselwa utshintsho olukhawulezileyo kwindonga yodonga ukuze kuqinisekiswe ukumila okuphuma rhoqo kunye nokulungiswa kokubumba okulula. Ukongezelela, iiprofayili ezinodonga oluncinci zine-elasticity engcono, kunye nobukhulu bodonga lwezinye ii-gussets, i-battens, njl. Kukho izicelo ezininzi zokulungiswa kweenkcukacha kuyilo, ezifana nokulungelelanisa ii-angles, ukutshintsha izikhombisi-ndlela, ukunciphisa i-cantilevers, ukwandisa izithuba, ukuphucula i-symmetry, ukulungelelanisa ukunyamezela, njl.

3. Isiphelo

Njengomyili, ukuze ufumane izibonelelo zezoqoqosho ezingcono kakhulu kwimveliso yeprofayili, zonke izinto zomjikelo wobomi bemveliso kufuneka ziqwalaselwe ngexesha loyilo, kubandakanywa iimfuno zomsebenzisi, uyilo, ukuvelisa, umgangatho, iindleko, njl., zama ukufikelela kwimpumelelo yophuhliso lwemveliso okokuqala. Ezi zifuna ukulandelela imihla ngemihla yokuveliswa kwemveliso kunye nokuqokelela kunye nokuqokelela ulwazi lokuqala ukuze uqikelele iziphumo zoyilo kunye nokuzilungisa kwangaphambili.

Ixesha lokuposa: Sep-10-2024