Ukwenziwa kweAluminiyam yindlela yokuvelisa ukunyamezelana okuphezulu kunye neendawo ezikumgangatho ophezulu ngokugalela i-aluminiyam etyhidiweyo kwidiyiti eyilwe ngokuchanekileyo nangobunjineli obuchanekileyo, ukungunda, okanye ifom. Yinkqubo esebenzayo yokuveliswa kwamalungu antsonkothileyo, antsonkothileyo, aneenkcukacha ezihambelana ncakasana neenkcukacha zoyilo lwantlandlolo.

Inkqubo yokuCasa iAluminiyam

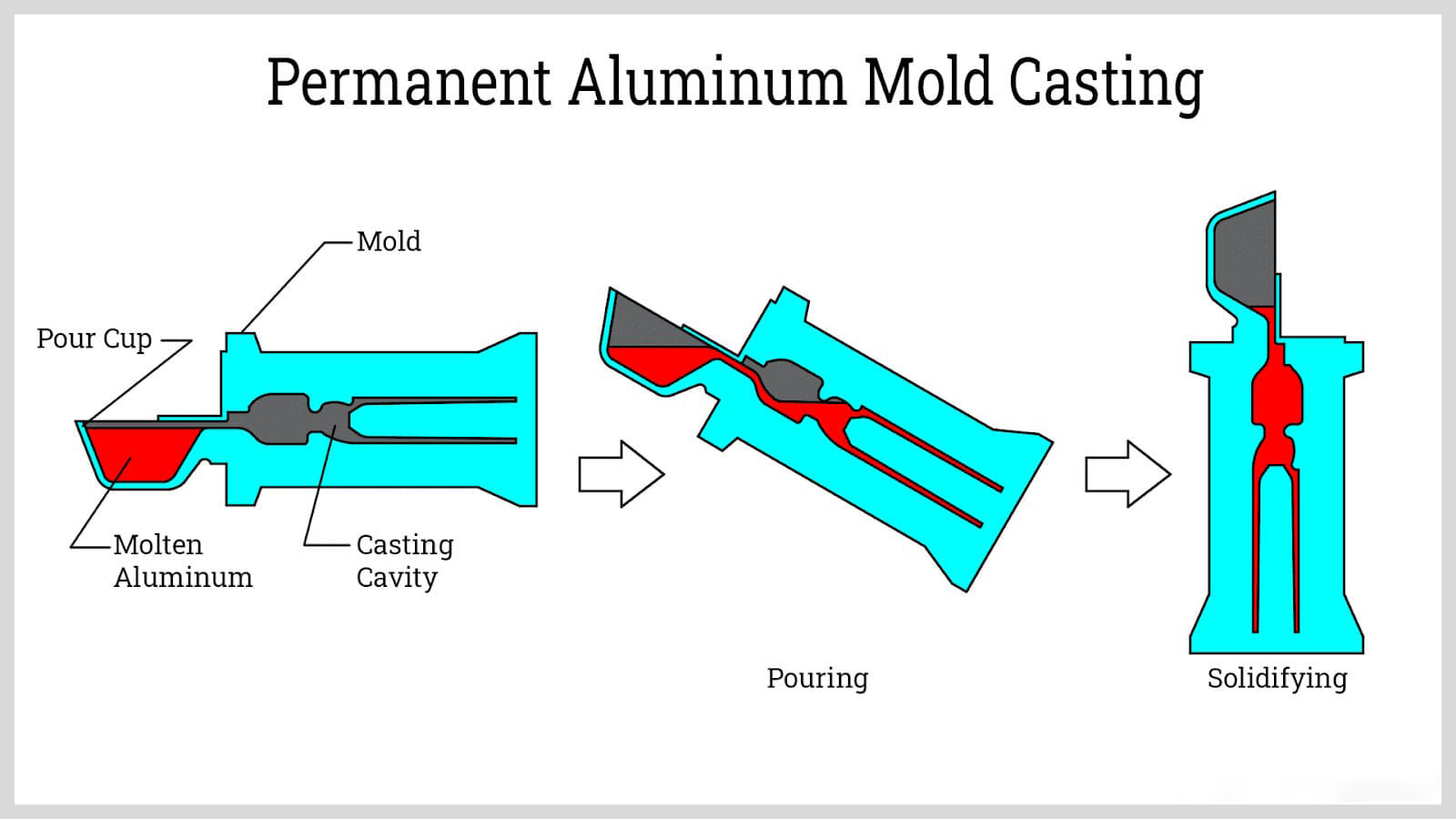

1.Permanent Mold Casting

Uninzi lweendleko zokubunjwa kwe-aluminiyam esisigxina kukwenziwa kwe-machining kunye nokubunjwa kwesikhunta, esiqhele ukwenziwa ngentsimbi engwevu okanye intsimbi. Ubumba bubunjwe kwimilo yejometri yenxalenye eyiliweyo kunye neenkcukacha kunye nokuma kwenxalenye eyahlulahlulwe ibe ngamacandelo amabini. Kwinkqubo yokutofa, i-halves ye-mold ivalwe ngokuqinileyo ukuze kungabikho moya okanye ukungcola. Umngundo ufudunyezwa phambi kokugalelwa kwe-aluminiyam etyhidiweyo, enokuthi ifakwe ileli, igalelwe, okanye itofwe.

Ekugqityweni kwenkqubo, isikhunta sivunyelwe ukupholisa ukuvumela ukuba inxalenye ye-aluminium iqine. Xa sele ipholile, inxalenye isuswa ngokukhawuleza kwi-mold ukukhusela ukubunjwa kweziphene.

Nokuba le nkqubo inokubonakala ilula kangakanani, yindlela yobuchwephesha yenzululwazi kunye nobuchwephesha bokuvelisa iindawo ezinomthamo ophezulu.

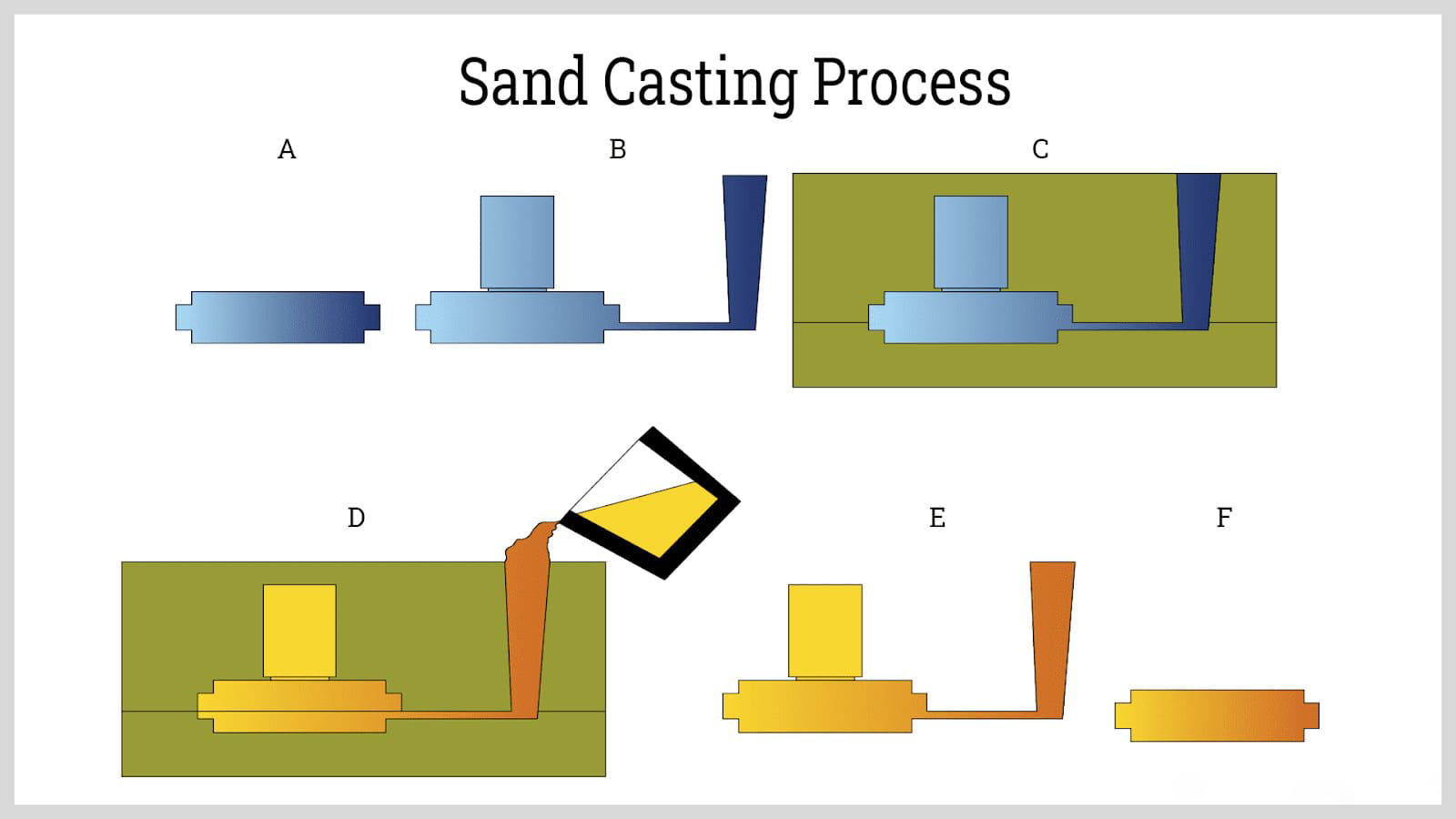

2.Ukuphosa kweSanti

Inkqubo yokugalela isanti ibandakanya ukupakisha isanti malunga nepateni enokusetyenziswa kwakhona enokwakheka, iinkcukacha, kunye nokucwangciswa kwemveliso yokugqibela. Okuqukwe kwipatheni zinyuka ezivumela ukuba isinyithi esityhidiweyo sigalelwe kwi-mold kunye ne-aluminiyam eshushu yondla i-casting ngexesha lokuqinisa ukukhusela i-shrinkage porosity.

Ibandakanyiwe kwipatheni yi-sprue evumela ukuba isinyithi esityhidiweyo sifakwe kwi-mold. Imilinganiselo yepateni inkulu kancinane kunemveliso ukuba iphendule ngokushwabana ngexesha lenkqubo yokupholisa. Isanti inobunzima kunye namandla okugcina imilo yepateni kwaye iyamelana nokusebenzisana nentsimbi etyhidiweyo.

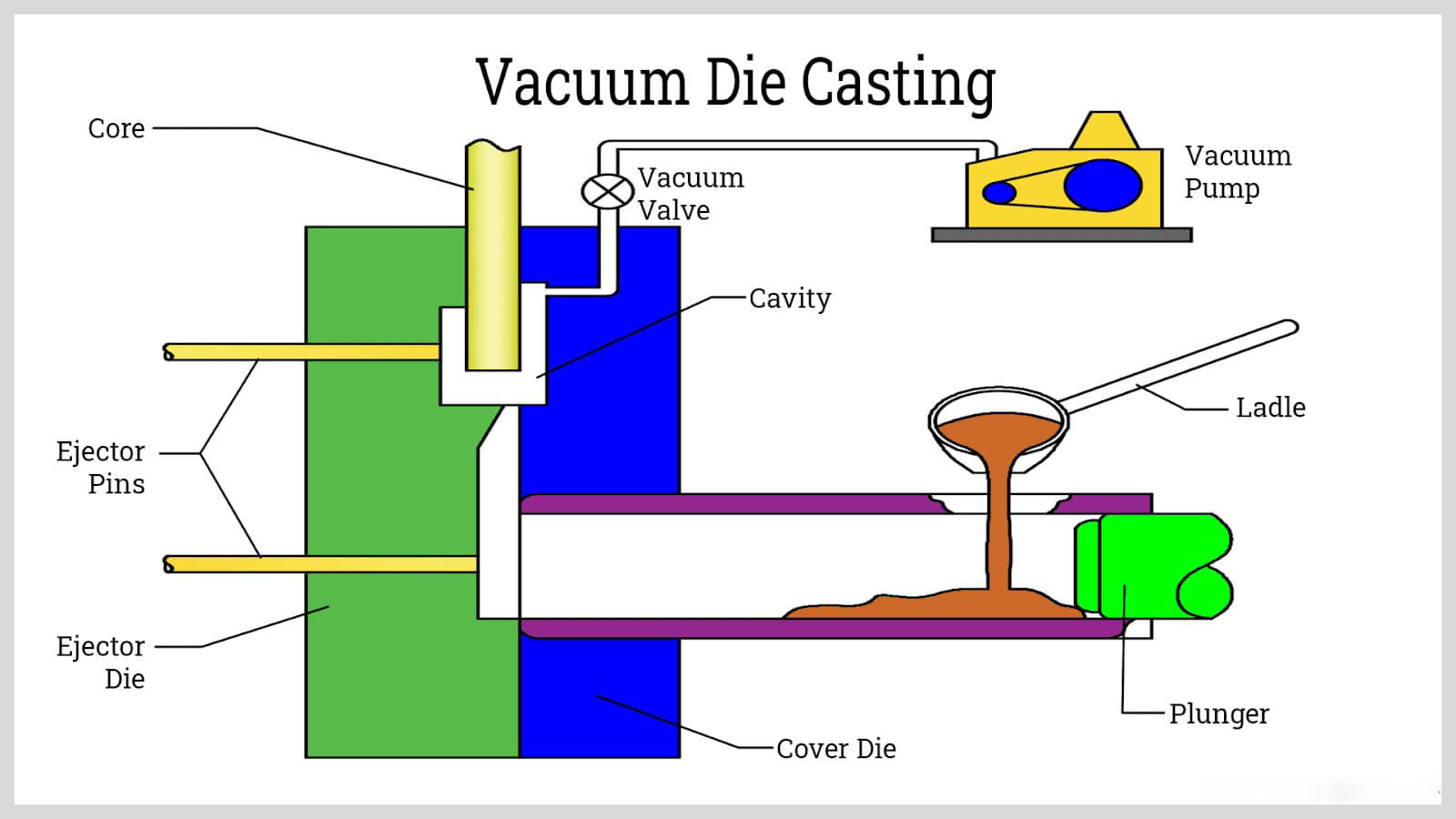

4.Vacuum Die Casting

4.Vacuum Die Casting Ivacuum die casting isebenzisa indlu yentsimbi engangeni moya enendawo yokuvula i-sprue emazantsi kunye nendawo yokufunxa phezulu. Inkqubo iqala ngokuntywilisela i-sprue ngaphantsi komphezulu we-aluminiyam etyhidiweyo. Ivacuum yenziwe kwi-receiver edala umahluko woxinzelelo phakathi komngxuma wokufa kunye ne-aluminiyam etyhidiweyo kwi-crucible.

Umahluko woxinzelelo ubangela ukuba i-aluminiyam etyhidiweyo ihambe iye phezulu kwi-sprue ukuya kumngxuma wokufa, apho i-aluminiyam etyhidiweyo iqina. Ukufa kuyasuswa kumamkeli, kuvulwe, kwaye inxalenye iyakhutshelwa.

Ukulawula i-vacuum kunye nokwahlukana koxinzelelo phakathi komgodi wokufa kunye ne-aluminium etyhidiweyo yenza kube lula ukulawula izinga lokuzalisa elifunekayo ngokuyilwa kwenxalenye kunye neemfuno zokungena. Ukulawulwa kwezinga lokuzalisa kwandisa amandla okumisela isandi senxalenye egqityiweyo.

Ukuntywiliselwa kwe-sprue ngaphantsi komphezulu we-aluminiyam etyhidiweyo kuqinisekisa ukuba i-aluminiyam etyhidiweyo iya kuba yeyona alloy ecocekileyo engena-oksidi kunye nenkunkuma. Amalungu acocekile kwaye anesandi kunye nezixhobo ezincinci zangaphandle.

5.Utyalo-mali lokuphosa

Ukugalelwa kotyalo-mali, okwakwaziwa njengokuphoswa kwewax elahlekileyo, kuqala ngokutofwa kwewax kwidayiti ukwenza ipatheni yemveliso egqityiweyo. Iipateni ezenziwe ngewax zincanyatheliswe kwi-sprue ukwenza uqwalaselo lwe-ike yomthi. Umthi uthi nkxu kwi-slurry amaxesha amaninzi, okwenza iqokobhe leceramic eyomeleleyo lijikeleze imilo yewax.

Emva kokuba i-ceramic imisiwe kwaye yomelele, ifudunyezwa kwi-autoclave ukugqiba ukutshiswa kwe-dewax. Ukufezekisa ukushisa okunqwenelekayo kwegobolondo, ifakwe ngaphambili ngaphambi kokuba izaliswe nge-aluminium etyhidiweyo, egalelwe kwi-sprue kwaye idlule kwichungechunge lwabagijimi kunye namasango kwi-molds. Xa iindawo ziqina, i-ceramic iyanqunyulwa ishiye umthi oqhagamsheleneyo ukuze usikwe emthini.

6.Lost Foam Casting

Inkqubo yokuphosa igwebu elahlekileyo lolunye uhlobo lotyalo-mali apho i-wax ithathelwa indawo nge-polystyrene foam. Ipateni ibunjwe ukusuka kwi-polystyrene kwindibano yeqela elifana nembaleki kunye ne-sprues yokuphosa utyalo-mali. Amaso e-polystyrene afakwe kwi-molds ye-aluminiyam eshushu ngoxinzelelo oluphantsi kunye nomphunga wongeziweyo ukwandisa i-polystyrene ukuzalisa imingxuma.

Ipateni ibekwe kwisanti exineneyo eyomileyo exutywe ukungcangcazela ukuze kupheliswe i-voids okanye iipokotho zomoya. Njengoko i-aluminium etyhidiweyo igalelwa kwisikhunta sesanti, i-foam iyatshiswa, kwaye i-casting yenziwa.

Ukusetyenziswa okuqhelekileyo kweAluminiyam yokuphosa

Ngenxa yeempawu zayo ezibalaseleyo zomzimba kunye neekhemikhali, amashishini amaninzi amakhulu asebenzisa i-aluminium ephosiweyo. Nazi iindlela ezimbalwa eziqhelekileyo zokusetyenziswa kwemathiriyeli.

1. Ishishini lezonyango

Abavelisi becandelo lezonyango baxhomekeke kwi-aluminium ephosa amandla abo kunye nobunzima bokwenza i-prosthetics, iitreyi zotyando, njl. Ngaphandle koko, inkqubo ifanelekile ukwenza iimilo eziyinkimbinkimbi kunye nezichanekileyo apho imboni eyaziwayo. Kwakhona, i-aluminiyam yinto efanelekileyo ngenxa yokunganyangeki kwayo ngenxa yokuba izixhobo ezininzi zonyango zidibana nolwelo lomzimba.

2. Ushishino lweemoto

Abavelisi bezixhobo zemoto baxhomekeke kwiisanti ze-aluminiyam kwiipropati zabo ezikhaphukhaphu ngaphandle kokuquka amandla kunye nokuqina. Ngenxa yoko, iye yaphucula ukusebenza kakuhle kwamafutha. Ngaphaya koko, ukwenza iinxalenye zeemoto ezinemilo entsonkothileyo kunye nenkqubo yokuphosa i-aluminium kulula. Iintsimbi ze-aluminiyam zifanelekile ukwenza iindawo ezifana neziqhoboshi kunye namavili okuqhuba.

3. Ishishini leCulinary

I-aluminium eyi-Cast iluncedo kwishishini lokupheka ngenxa yokuqina kwayo, ukuxhathisa ukubola, ubunzima, kunye nokuqhuba ubushushu obugqwesileyo. Ngaphandle koko, izinto eziphathekayo zifanelekile ukwenza i-cookware ngenxa yokutshatyalaliswa kobushushu obugqwesileyo, oko kukuthi, inokutshisa kwaye iphole ngokukhawuleza.

4. Ishishini leenqwelomoya

Amalungu e-aluminiyam afanelekile kwishishini leenqwelomoya ngenxa yobunzima babo kunye namandla. Ubunzima bayo obulula buvumela inqwelo-moya ukuba isebenzise amafutha amancinci ukuze ithwale ubunzima obuninzi.

Umthombo:

https://www.iqsdirectory.com/articles/die-casting/aluminum-casting.html

https://waykenrm.com/blogs/cast-aluminium/#Common-Applications-of-Casting-Aluminium

Ihlelwe nguMay Jiang esuka kwiMAT Aluminium

Ixesha lokuposa: Jul-26-2023