1 Isishwankathelo

Inkqubo yokuvelisa iprofayili yokufakelwa kwe-thermal yokufakelwa inzima kakhulu, kwaye inkqubo yokuthunga kunye ne-laminating isemva kwexesha. Iimveliso ezigqityiweyo eziqukuqela kule nkqubo zigqityezelwa ngomsebenzi onzima wabasebenzi abaninzi abaphambili. Nje ukuba iimveliso zenkunkuma zivele kwinkqubo edityanisiweyo yokuqhawula, ziya kuthi Ukuba ibangela ilahleko enkulu yezoqoqosho, oko kuya kukhokelela kwilahleko yeziphumo ezininzi zangaphambili zabasebenzi, okukhokelela kwinkcitho enkulu.

Ngexesha lokuveliswa kweeprofayili zokufakelwa kwe-thermal, iiprofayili zihlala zichithwa ngenxa yezinto ezahlukeneyo. Isizathu esiphambili se-scrap kule nkqubo kukuqhekeka kweenotshi ze-heat-insulating strip. Zininzi izizathu zokuqhekeka kwenotshi ye-heat-insulating strip notch, apha sigxile kakhulu kwinkqubo yokufumana izizathu zeziphene ezinje ngomsila oshwabeneyo kunye ne-stratification ebangelwa yinkqubo ye-extrusion, ekhokelela ekuqhekekeni kweenotshi ze-aluminium alloy ubushushu bokufakelwa kweeprofayili ngexesha lokuthunga kunye ne-laminating, kunye nokusombulula le ngxaki ngokuphucula ukubumba kunye nokuphucula le ngxaki.

2 Iimeko zengxaki

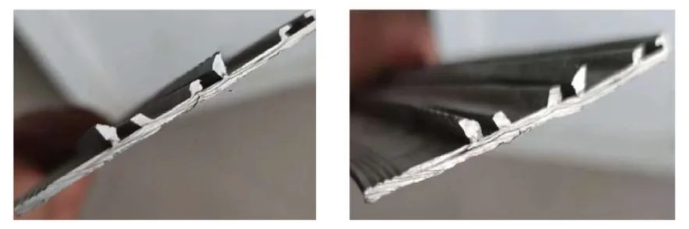

Ngexesha lenkqubo yokuvelisa ubushushu bokufakelwa kobushushu, ukuqhekeka kwebhetshi yeenotshi ezikhusela ubushushu kwavela ngequbuliso. Emva kokutshekisha, i-phenomenon yokuqhekeka inomzekelo othile. Zonke iintanda ekupheleni kwemodeli ethile, kwaye ubude be-crack bufana. Kuphakathi koluhlu oluthile (20-40cm ukusuka ekupheleni), kwaye luya kubuyela kwisiqhelo emva kwexesha lokuqhekeka. Imifanekiso emva kokuqhekeka iboniswe kuMfanekiso 1 kunye nomfanekiso wesi-2.

3 Ukufumana ingxaki

I-1) Okokuqala, hlela iiprofayili ezinengxaki kwaye uzigcine kunye, jonga into eqhekekileyo nganye nganye, kwaye ufumanise izinto eziqhelekileyo kunye nokungafani kokuqhekeka. Emva kokulandelela ngokuphindaphindiweyo, i-phenomenon of cracking inomzekelo othile. Yonke iyaqhekeka ekupheleni kwemodeli enye. Ubume bemodeli eqhekekileyo yinto eqhelekileyo yezinto eziphathekayo ngaphandle kwecavithi, kwaye ubude obuqhekezayo bungaphakathi koluhlu oluthile. Ngaphakathi (20-40cm ukusuka ekupheleni), iya kubuyela kwisiqhelo emva kokuqhekeka ixesha elithile.

I-2) Ukusuka kwikhadi lokulandelela imveliso yale bhetshi yeeprofayili, sinokufumanisa inani lokubumba elisetyenziswe kwimveliso yolu hlobo, ngexesha lokuvelisa, ubungakanani bejometri yenotshi yalo mzekelo ivavanywa, kunye nobukhulu bejometri yomgca wokushisa ubushushu, iipropathi zomatshini zeprofayili kunye nobunzima bomhlaba buphakathi koluhlu olufanelekileyo.

3) Ngexesha lenkqubo yokuvelisa izinto ezidibeneyo, iiparamitha zenkqubo edibeneyo kunye nemisebenzi yokuvelisa ilandelwe. Kwakungekho zinto zingaqhelekanga, kodwa kwakusekho iintanda xa ibhetshi yeeprofayili zaveliswa.

I-4) Emva kokutshekisha ukuphuka kwi-crack, ezinye izakhiwo ezingapheliyo zifunyenwe. Ukuqwalasela ukuba imbangela yale nto kufuneka ibangelwe yiziphene ze-extrusion ezibangelwa yinkqubo ye-extrusion.

I-5) Ukususela kule nto ingasentla, kunokubonwa ukuba imbangela yokuqhekeka ayikho ubunzima beprofayili kunye nenkqubo edibeneyo, kodwa ekuqaleni inqunywe ukuba ibangelwa yiziphene ze-extrusion. Ukuze kuqinisekiswe ngakumbi unobangela wengxaki, olu vavanyo lulandelayo lwenziwa.

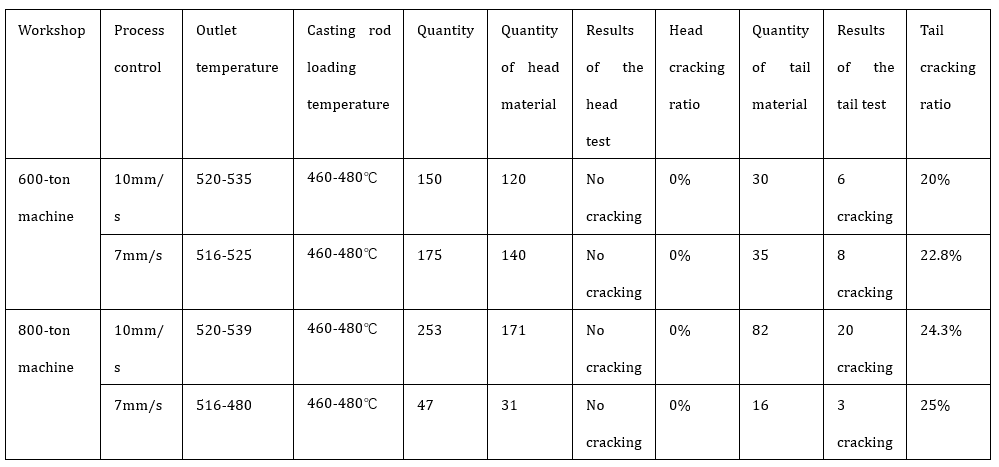

6) Sebenzisa isethi efanayo yokubumba ukwenza iimvavanyo kumatshini ohlukeneyo wetoni kunye nezantya ezahlukeneyo ze-extrusion. Sebenzisa umatshini weetoni ezingama-600 kunye nomatshini weetoni ezingama-800 ukwenza uvavanyo ngokulandelelanayo. Phawula intloko yezinto eziphathekayo kunye nomsila wezinto eziphathekayo ngokwahlukileyo kwaye uzipakishe kwiibhasikithi. Ubunzima emva kokuguga kwi-10-12HW. Indlela ye-alkaline ye-corrosion yamanzi yayisetyenziselwa ukuvavanya iphrofayili entloko kunye nomsila wezinto eziphathekayo. Kwafunyaniswa ukuba umsila wezinto eziphathekayo unomsila oshwabeneyo kunye ne-stratification phenomena. Unobangela wokuqhekeka kwafunyaniswa ukuba ubangelwa kukushwabana komsila kunye ne-stratification. Imifanekiso emva kwe-alkali etching iboniswe kwiMifanekiso 2 kunye ne-3. Iimvavanyo ezihlanganisiweyo zenziwa kule bhetshi yeeprofayili ukujonga into yokuqhekeka. Idatha yovavanyo iboniswe kwiThebhile 1.

Amanani 2 kunye ne-3

I-7) Ukusuka kwidatha kwitheyibhile engentla, kunokubonwa ukuba akukho ngqungquthela entloko yezinto eziphathekayo, kwaye umlinganiselo wokuqhawula umsila wezinto eziphathekayo zikhulu. Isizathu sokuqhekeka asinanto encinci kunye nobukhulu bomatshini kunye nesantya somatshini. Umlinganiselo wokuqhekeka kwezinto zomsila ngowona mkhulu, ohambelana ngokuthe ngqo nobude be-sawing yezinto zomsila. Emva kokuba inxalenye yokuqhekeka ifakwe emanzini e-alkaline kwaye ihlolwe, umsila wokunciphisa kunye ne-stratification iya kubonakala. Emva kokuba umsila oshwabeneyo kunye neenxalenye ze-stratification zinqunyulwe, akuyi kubakho ukuqhekeka.

4 Iindlela zokusombulula iingxaki kunye namanyathelo okuthintela

I-1) Ukuze kuncitshiswe i-notch cracking ebangelwa sesi sizathu, ukuphucula isivuno, nokunciphisa inkunkuma, la manyathelo alandelayo athatyathwa ukulawula imveliso. Esi sisombululo sifanelekile kwezinye iimodeli ezifanayo ezifana nale modeli apho i-extrusion die ifa flat. Umsila we-shrink kunye ne-stratification phenomena eveliswa ngexesha lokuvelisa i-extrusion iya kubangela iingxaki ezisemgangathweni ezifana nokuqhekeka kweenotshi zokugqibela ngexesha lokudibanisa.

2) Xa wamkela isikhunta, lawula ngokungqongqo ubungakanani benotshi; sebenzisa into enye yokwenza i-mold integral, yongeza amagumbi e-welding ephindwe kabini kwi-mold, okanye uvule i-mold yokwahlukana yobuxoki ukunciphisa impembelelo yekhwalithi yomsila wokunciphisa kunye ne-stratification kwimveliso egqityiweyo.

3) Ngexesha lokuvelisa i-extrusion, umphezulu wentonga ye-aluminium kufuneka ihlambuluke kwaye ingabi nothuli, ioli kunye nokunye ukungcola. Inkqubo ye-extrusion kufuneka yamkele imo ye-extrusion ethotyiweyo. Oku kunokunciphisa isantya sokukhupha ekupheleni kwe-extrusion kunye nokunciphisa umsila wokunciphisa kunye ne-stratification.

I-4) Iqondo lokushisa eliphantsi kunye ne-speed extrusion lisetyenziswa ngexesha lokuveliswa kwe-extrusion, kwaye ukushisa kwentonga ye-aluminium kumatshini ilawulwa phakathi kwe-460-480 ℃. Iqondo lokushisa lokungunda lilawulwa kwi-470 ℃ ± 10 ℃, iqondo lokushisa lombhobho we-extrusion lilawulwa malunga ne-420 ℃, kwaye i-extrusion outlet ye-extrusion ilawulwa phakathi kwe-490-525 ℃. Emva kwe-extrusion, ifeni ivuliwe ukupholisa. Ubude obushiyekileyo kufuneka bonyuswe ngaphezu kwe-5mm kunesiqhelo.

I-5) Xa uvelisa olu hlobo lweprofayili, kungcono ukusebenzisa umatshini omkhulu ukwandisa amandla okugqithisa, ukuphucula iqondo lokudibanisa isinyithi, kunye nokuqinisekisa ubuninzi bezinto eziphathekayo.

6) Ngexesha lokuvelisa i-extrusion, ibhakethi lamanzi e-alkali kufuneka lilungiswe kwangaphambili. Umsebenzisi uya kubona umsila wezinto eziphathekayo ukujonga ubude bomsila oshwabeneyo kunye ne-stratification. Imigca emnyama kumphezulu we-alkali-echetshiweyo ibonisa ukuba umsila oshwabeneyo kunye ne-stratification yenzekile. Emva kokubona ngakumbi, Kuze kube yilapho i-cross-section ikhanya kwaye ayinayo imigca emnyama, jonga ii-3-5 iintonga ze-aluminiyam ukuze ubone utshintsho lobude emva kokushwabana komsila kunye ne-stratification. Ukuze ugweme ukuncipha komsila kunye ne-stratification ekuzisweni kweemveliso zeprofayili, i-20cm yongezwa ngokweyona ende kakhulu, inqume ubude bomsila womsila we-mold set, yabona inxalenye eyingxaki kwaye iqale ukusika kwimveliso egqityiweyo. Ngethuba lokusebenza, intloko kunye nomsila wezinto eziphathekayo unokugungxulwa kwaye usasazwe ngokuguquguqukayo, kodwa iziphene akufanele ziziswe kwimveliso yeprofayili. Ujongwe kwaye uhlolwe ngokuhlolwa komgangatho womatshini. Ukuba ubude bomsila we-shrink kunye ne-stratification kuchaphazela isivuno, susa isikhunta ngexesha kwaye unciphise ukubumba kude kube yinto eqhelekileyo ngaphambi kokuba imveliso eqhelekileyo iqale.

5 Isishwankathelo

1) Iibhetshi ezininzi zeeprofayili zemicu yokugquma ubushushu eziveliswe kusetyenziswa ezi ndlela zingentla zavavanywa kwaye akukho notshi ifana nokuqhekeka okwenzekayo. Iimpawu zeempawu ze-shear zeeprofayili zonke zifikelele kumgangatho wesizwe we-GB / T5237.6-2017 iimfuno "Iiprofayili ze-Aluminium Alloy Building Numbers No. 6 Part: for Insulating Profiles".

2) Ukuze kuthintelwe ukwenzeka kwale ngxaki, inkqubo yokuhlola imihla ngemihla iye yaphuhliswa ukujongana nengxaki ngexesha kwaye yenza izilungiso zokuthintela iiprofayili eziyingozi ukuba zigeleze kwinkqubo edibeneyo kunye nokunciphisa inkunkuma kwinkqubo yokuvelisa.

I-3) Ngaphandle kokuphepha ukuchithwa okubangelwa yiziphene ze-extrusion, i-shrink umsila kunye ne-stratification, kufuneka sihlale siqwalasela isiganeko esiqhekezayo esibangelwa yizinto ezifana nejometri yenotshi, ukuqina komphezulu kunye neempawu zemishini yezinto eziphathekayo kunye neeparitha zenkqubo yenkqubo edibeneyo.

Ihlelwe nguMay Jiang esuka kwiMAT Aluminium

Ixesha lokuposa: Jun-22-2024