Ekuguqukeni koshishino lwe-aluminium, itekhnoloji yokucoca iinkozo ihlala idlala indima ephambili ekumiseleni umgangatho wemveliso kunye nokusebenza kakuhle kwemveliso. Ukususela ekusekweni kwe-Tp-1 indlela yokuvavanya i-grain refiner kwi-1987, i-shishini lide lixakeke yimingeni eqhubekayo-ingakumbi, ukungazinzi kwe-Al-Ti-B yokucoca okusanhlamvu kunye namazinga aphezulu okongeza afunekayo ukuze kugcinwe ukusebenza kokulungiswa. Kwaba ngo-2007 apho inguqu yezobuchwepheshe eyaqalwa elabhoratri yatshintsha ngokusisiseko indlela yokuphosa i-aluminiyam.

Ngempumelelo yayo ye-Optifine super grain refine, i-MQP iphumelele umtsi womyinge ekucokiseni ukusebenza kakuhle. Ukwamkela ingcamango entsha ethi "okuncinci kuninzi," i-MQP ibonelele abavelisi be-aluminiyam behlabathi indlela entsha eya ekunciphiseni iindleko kunye nokuphucula ukusebenza kakuhle. Eli nqaku ligocagoca kwindaleko yobuchwepheshe, imigaqo yenzululwazi, usetyenziso lwehlabathi lokwenyani, kunye nenkangeleko yexesha elizayo yemveliso yoguqulo ye-MQP, ebonisa indlela eyichaze ngokutsha imigangatho yoshishino.

I. Ukuphumelela kweTekhnoloji: Ukusuka kwiMida yeOpticast ukuya ekuZalweni koMcoci oMkhulu.

Yonke impumelelo enkulu yezenzululwazi iqala ngovavanyo kwakhona olubalulekileyo lobulumko obuqhelekileyo. Kwi-2007, uDkt. Rein Vainik, ebonisa iminyaka elishumi yomsebenzi kunye ne-Opticast process optimization technology for grain refinement, wayejongene nenyaniso enzima: nangona isithembiso sayo, inkqubo ayiphumelelanga ukunqoba umba oqhubekayo wokusebenza okungazinzanga kumanqanaba asezantsi okongezwa kwe-Al-Ti-B yokucoca okusanhlamvu.

I-Opticast yakhiwe kwingqiqo ebonakala igqibelele-ilungisa imilinganiselo yokongeza isisulungesi ngokusekelwe kwiintlobo ze-alloy kunye nomxholo we-scrap ukufikelela kulawulo oluchanekileyo lwedosi ephantsi. Nangona kunjalo, ingxelo yomsebenzisi ibonise ukuba amazinga aphantsi okongezwa kwe-Al-Ti-B azinzileyo kuphela ixesha elifutshane. Nje ukuba utshintsho lwe-wire spool lwenzekile, ukukhuthuka kweenkozo kwalandela ngokukhawuleza. Oku kuqhawulwa konxibelelwano kunyanzelise uGqr Vainik ukuba aphinde ajonge umba ongundoqo. Indlela ekhoyo igxile kuphela kwizinto eziguquguqukayo zealloyi, ityeshela ukuguquguquka kwamandla angaphakathi okucokisa isisulungesi sengqolowa. Ngokwenyani, ukunqongophala kobungakanani bazo zombini ezi ziguquguqukayo zenza oko kubizwa ngokuba "lulawulo oluchanekileyo" akukho nto ngaphandle kokukhohlisa elabhoratri.

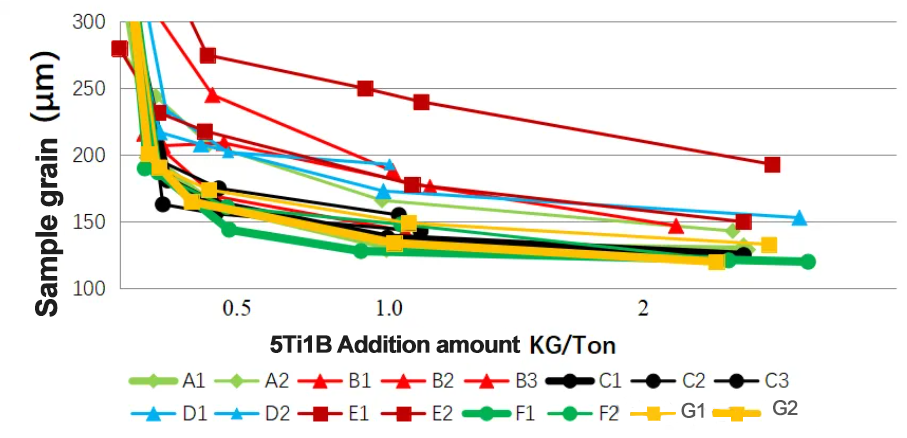

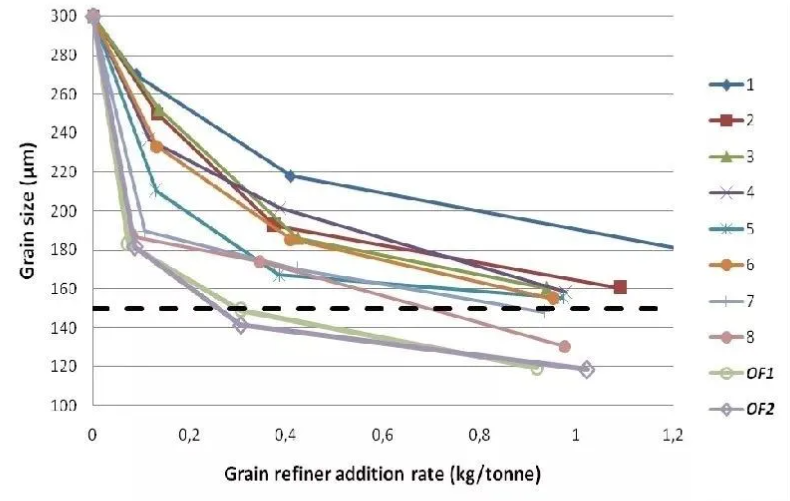

Olu tshintsho lweparadigm luye lwabeka isiseko semveliso yesisulungesi sengqolowa. Ukutshintsha ugxininiso ukusuka kwi-alloy ye-aluminium ukuya kwi-Al-Ti-B yokucoca ingqolowa ngokwayo, uGqr. Vainik wenza iimvavanyo ze-curve yokucoca iinkozo kwiibhetshi ezihlukeneyo ze-16 zeemveliso ze-5Ti1B usebenzisa i-Opticast's standardized test protocol. Ngaphantsi kokwakheka kweekhemikhali ezifanayo kunye neemeko zokupholisa, yibhetshi kuphela eyahluka-hlukeneyo. Iziphumo zaziyothusa—kwaneebhetshi ezivela kumenzi ofanayo kunye nomgangatho zibonise umahluko omkhulu kumandla okucoca. Idatha ibonise indawo yentlungu yexesha elide: indlela ye-Tp-1, esetyenziswa ukususela kwi-1987, ayiphumelelanga ukulinganisa umthamo wangempela wokucocwa kweemveliso ze-Al-Ti-B.

Ngexesha elifanayo, i-MQP yafumana i-Opticast AB. Umseki uJohn Courtenay, eqonda iimfuno ezingxamisekileyo zemarike, ucebise imbono ephazamisayo: ukudibanisa indlela yokuphucula ye-Opticast kunye "nomthamo omkhulu wokucokisa" isisulungesi sengqolowa. Ugxininiso luya kuthi lusuke ekulawuleni amazinga okongezwayo luye ekomelezeni uphuculo olusebenzayo, lushukuxa ingcambu yemingeni yoshishino. Olu tshintsho lwakhokelela ekuchazweni ngokutsha kwento eyayiquka “umsulungekisi wengqolowa osebenza kakuhle kakhulu.” I-MQP yayithiya i-Optifine Super Grain Refiner kwaye yapapasha inkcazo yayo esemthethweni kwi-Light Metals Ehlelwe yi-TMS 2008-i-grain refiner ebonakaliswe ngowona mandla aphezulu e-nucleation.

Unyaka ka-2007 ngoku uqondwa ngokubanzi njengemvelaphi yesisulungeki sengqolowa ephezulu. Kwaphawula inguquko xa ishishini laqondayo: undoqo ekucokiseni ukutya okuziinkozo “ayisiyondlela yokongeza ingakanani na,” kodwa “ubuchule bomsulungekisi.” Ngolu hlengahlengiso-ukusuka ekuqondeni ukuguquguquka ukuya kwinkcazo yemveliso-MQP ivule ixesha elitsha lokuveliswa kwemveliso ephezulu kwi-aluminium processing.

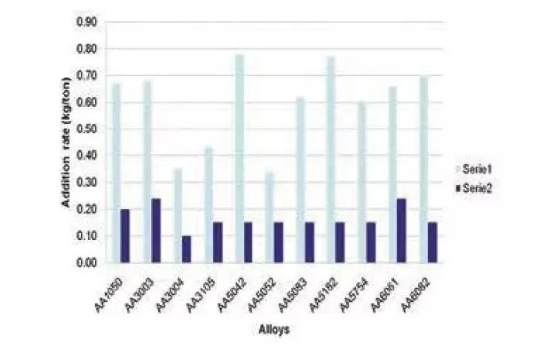

Igophe lesakhono sokusulungekisa okuziinkozo kwe-aluminiyam eqhelekileyo ye-titanium boron ibonisa ukuguquguquka okumangalisayo kwesakhono sokusulungekisa ukutya okuziinkozo kwe-aluminiyam titanium boron.

Ikhono lokucoca i-curves No. 1-8 libonisa umehluko omkhulu kwikhono lokucoca kwiibhetshi ezi-8 zeemveliso ezivela kumenzi ofanayo.

I-OF-1 kunye ne-OF-2 ngamagophe okucokisa amandla e-Optifine super aluminium titanium boron, ebonisa ukuba imveliso inamandla okucoca asebenzayo kunye nozinzile.

II. ISiseko seNzululwazi: Umahluko weNqanaba leAtom

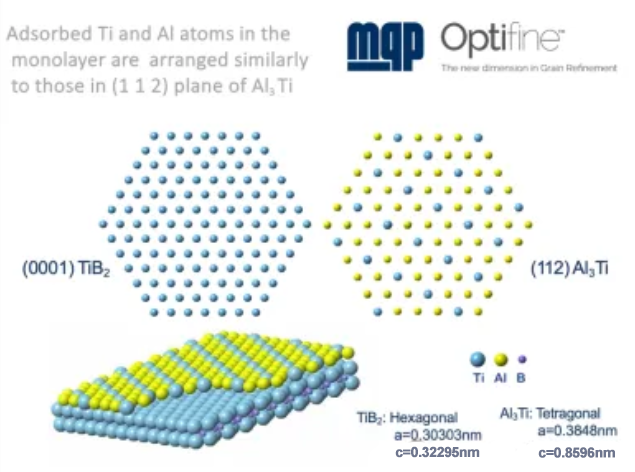

Utshintsho oluhlala luhleli lufuna ukuqonda okunzulu kwemigaqo yenzululwazi esisiseko. Ukusebenza okumangalisayo kwe-Optifine super grain refine kulele ekucaciseni kwayo inqanaba leatom yeendlela zokwenziwa kweenkozo eziziinkozo. Kwi-2021, i-MQP kunye neYunivesithi yaseBrunel yaseLondon iqhube ngokudibeneyo iprojekthi yophando "I-Nucleation Mechanism ye-α-Aluminium kwi-TiB₂ Surfaces," inikezela ubungqina obucacileyo besayensi bokusebenza okuphezulu kwe-super grain refiner.

Ukusebenzisa i-electron microscopy ye-high-resolution transmission (HR-TEM), iqela lophando lenze ukufunyanwa kwe-groundbreaking kwisikali se-athomu: ubukho be-TiAl₃ iileyile ze-athomu kumphezulu we-TiB₂ particles. Lo mahluko we-microstructure utyhile imfihlelo esisiseko emva kokwahluka ekusebenzeni kakuhle. Xa kuthelekiswa iisampulu ezimbini-enye kunye nokusebenza kakuhle kwe-50% kunye enye ne-123%-kwafunyaniswa ukuba i-7 kwi-8 ye-TiB₂ amasuntswana kwisampulu esebenzayo ephezulu inomaleko we-interface we-2DC Ti₃Al, ngelixa i-1 kuphela kwi-6 yenze njalo kwisampulu ephantsi.

Oku kufunyanisiweyo kubhukuqe inkolelo yoshishino lwemveli yokuba amasuntswana e-TiB₂ kuphela ayesisiseko senucleation yengqolowa. Endaweni yoko, uphando lwe-MQP lubonise ukuba umgangatho kunye nobuninzi beeleya ezihlangeneyo zobuso zizinto eziyinyani zokumisela ukuba nokwenzeka kwenucleation. Abasulungeki bengqolowa abakumgangatho ophezulu babonisa ulungelelwaniso oluphezulu kakhulu lwe-atom kunye nokuthembeka kumasuntswana e-TiB₂ xa kuthelekiswa neemveliso eziqhelekileyo ze-Al-Ti-B. Le nzuzo ye-microstructural iguqulela ngokuthe ngqo ekusebenzeni kwe-macroscopic-iyunifomu eninzi kunye neenkozo ezintle phantsi komlinganiselo ofanayo wokongezwa, okhokelela kumgangatho ophezulu wemveliso.

Ukulinganisa le yantlukwano, i-MQP iphuhlise indlela yovavanyo olunelungelo elilodwa lomenzi wokuSebenza ngoNcitho oluLulemeneyo (RRE), oluchazwe njengepesenti. Ibalwa ngokuthelekisa inani leenkozo ezenziwe ngokwe ppm B nge mm³ yesampulu yovavanyo kwireferensi esemgangathweni. Xa i-RRE idlula i-85%, imveliso ihlelwa njengemveliso ye-Optifine super Al-Ti-B. Lo mlinganiselo wobungakanani awuboneleli nje kuphela ngesiseko senzululwazi sovavanyo lomsebenzi kodwa uvumela abavelisi ukuba benze izigqibo ezizizo ezisekelwe kumandla okwenene wokusulungekisa.

Ukusuka ekufunyanweni kwinqanaba le-atom ukuya kwiimethrikhi zobungakanani, i-MQP iye yabeka isiseko esiluqilima sezenzululwazi sesisulungesi sengqolowa esikhulu. Uhlaziyo ngalunye kuthotho lwe-Optifine luxhaswa ziindlela ezichaziweyo zeatom kunokuba uqikelelo lwamava.

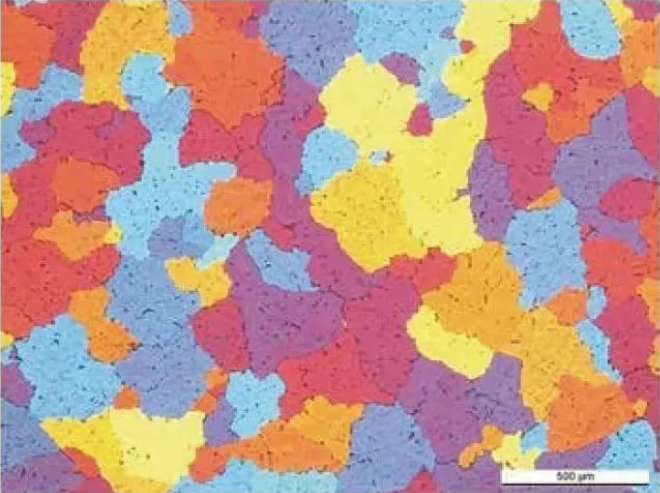

Ulwakhiwo lwe-alloy ye-AA6060 ephathwa nge-Optifine grain Refine. Umlinganiselo wokongezwa ngu-0.16kg/t, ASTM=2.4

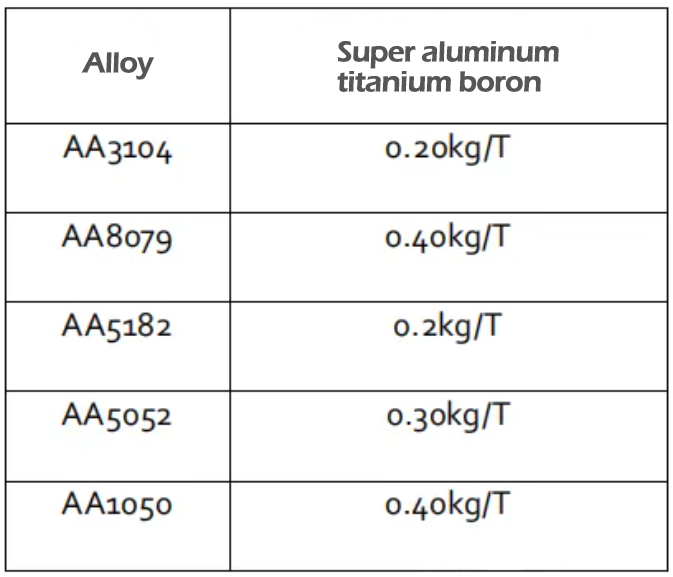

Isixa se-Optifine (blowu emnyama) isisulungesi sengqolowa xa sithelekiswa ne-TiBAI eqhelekileyo (eblue blue) isisulungesi sengqolowa esifunekayo kwialloyi ye-aluminiyam.

III. Ukuphindaphinda kweMveliso: UkuPhumelela kwiNdlela yokuSebenza ngokuPhakamileyo

Ukubaluleka kwayo nayiphi na iteknoloji ilele kubuchule obutsha obuqhubekayo. Ukusukela ekuqaleni kwayo, i-MQP iye yasebenzisa amandla ayo e-R&D eyomeleleyo ukunyusa ngokuphindaphindiweyo umgca wemveliso ye-Optifine, ukutyhala imida ekusebenzeni kakuhle kunye nozinzo. Ukusuka kwi-Optifine31 100 yantlandlolo ukuya kwi-Optifine51 100 kwaye ngoku i-Optifine51 125 ephezulu yokusebenza, isizukulwana ngasinye sizuze ukonyuka okukhulu kwi-RRE, ukuguqulela ngokuthe ngqo kumazinga ancitshisiweyo okongeza-ibandakanya ifilosofi ye-MQP "yomgangatho phezu kobuninzi."

Ukukhutshwa kokuqala, i-Optifine31 100, ngokukhawuleza yabonisa amandla ayo okuphazamisa. Ngamanqanaba e-RRE ayodlula kude iimveliso zemveli, igcine ukucokiswa okuziinkozo ngelixa isika amaxabiso okongezwa ngaphezulu kwe-50% xa kuthelekiswa nemilinganiselo yeshishini. Le mpumelelo yaqinisekisa ingqikelelo yesisulungesi seenkozo eziphezulu kwaye yabeka isiseko sophuculo lwexesha elizayo.

Njengoko iimfuno zoshishino zanda, i-MQP yazisa i-Optifine51 100, eyaphucula ukufana kwe-TiB₂ yokusabalalisa i-particle ngelixa igcina uzinzo. Ihambise malunga ne-20% ephezulu ye-RRE kuneyokuqala, ivumela ukucutha okongeziweyo kwe-15-20% kwiireyithi ezongezelelweyo-ezilungele i-aerospace kunye nezixhobo zokwakha i-premium apho umgangatho kunye nokuhambelana kubaluleke kakhulu.

Kwincopho yoluhlu lwangoku yi-Optifine51 125, ukuphumeza i-RRE ye-125%. Oku kubangelwe kwizinga eliphezulu kakhulu lokuqulunqa i-2DC Ti₃Al interface layer kwi-TiB₂ particles. Idatha yovavanyo iqinisekisa ukuba amathuba e-nucleation yale mveliso ngamaxesha angama-2-3 aphezulu kunezinye iindlela eziqhelekileyo, ukugcina ukusebenza okuzinzile nakwiinkqubo ze-alloy eziyinkimbinkimbi okanye i-high-recycled-content-melts. Kubenzi beemveliso ze-aluminiyam zexabiso eliphezulu, i-Optifine51 125 inciphisa iindleko zokucoca nge-70% kwaye inciphisa ngokumangalisayo i-scrap ebangelwa iinkozo ezirhabaxa.

Ngo-2025, i-MQP yabhengeza isicwangciso sayo semveliso ye-Optifine502 eCocekileyo, yandisa ukusungulwa kwezinto ezintsha. Ujoliso lweziphene zomhlaba, olu tshintsho lulawula ngokuchanekileyo ubuninzi be-TiB₂ ukunciphisa i-particle agglomeration ngelixa ugcina ukusebenza kakuhle. Ikulungele ukusebenzela usetyenziso olunje ngeefoyile zealuminiyam ezigudileyo kunye neepaneli zokugqibezela isipili, ukusombulula omnye umngeni weshishini elide elide.

Ukusuka ekomelezeni imfezeko ukuya ekuphuculeni umgangatho womphezulu, ukuvela kwemveliso ye-MQP ngokucacileyo ilandela ingqiqo enye engundoqo: eqhutywa yinzululwazi, into entsha egxile kumthengi ebumba ngokutsha ikhonkco lexabiso elipheleleyo lokusetyenzwa kwe-aluminiyam.

IV. UkuQinisekiswa kweHlabathi: Ukusukela kwangethuba lokumkelwa kwangethuba ukuya kwiMigangatho yoShishino

Ixabiso letekhnoloji entsha ekugqibeleni lingqinwa ngokwamkelwa ngokubanzi. Ngo-2008, xa i-Hulamin yaseMzantsi Afrika yaba yinkampani yokuqala ukuvavanya i-Optifine super grain refiner, bambalwa ababelindele ukuba eso sigqibo sibaluleke kangakanani na. Ukuyisebenzisa kwimveliso ye-alloy ye-AA1050, i-Hulamin iphumelele iziphumo ezimangalisayo-ukunciphisa ukongezwa kwe-refiner ukusuka kwi-0.67 kg / ton ukuya kwi-0.2 kg / ton, i-70% yokulondoloza. Oku akuthobanga iindleko kuphela kodwa kwaqinisekisa ukuthembeka kokwenyani kwemveliso.

Impumelelo kaHulamin yavula imarike yehlabathi ye-Optifine. Abavelisi be-aluminiyam abaphambili balandela ngokukhawuleza. I-Sapa (kamva yafunyanwa yi-Hydro) yakhupha i-Optifine kuzo zonke izityalo zayo zaseYurophu, inciphisa ukusetyenziswa kwesisulungesi ngomyinge wama-65% kwiialloyi ezininzi. I-Aleris (ngoku eyiNovelis) isetyenziswe kwimveliso yamaphepha eemoto, iphucula iipropati zoomatshini ngelixa inciphisa ukulahlwa kwesitampu. I-Alcoa iyifake kwimveliso ye-aluminium ye-aerospace-grade, ifezekisa ulawulo oluchanekileyo lokuqamba ngokudibanisa i-Optifine kunye ne-Opticast.

Ukungena e-China kwi-2018, i-MQP yakhawuleza yafumana i-traction kwicandelo le-aluminium ephezulu yelizwe. Njengomvelisi omkhulu we-aluminium kunye nomthengi wehlabathi, i-China idinga ngokukhawuleza ukunciphisa iindleko kunye nokunyusa umgangatho. Ukwaziswa kwe-Optifine kuhambelana ngokugqibeleleyo nepivot yelizwe kwimveliso ekumgangatho ophezulu.

Omnye umzekelo obalaseleyo yinkampani yaseTshayina ye-aluminium foil evelisa iifoyile ezichaneke kakhulu, apho abacoci bemveli babangele imiba efana neepinhole kunye nokuqhawuka kweefoyile ngenxa yokwahluka kwebhetshi. Emva kokutshintshela kwi-Optifine51 100, amazinga ongezelelweyo ahla ukusuka kwi-0.5 kg / ton ukuya kwi-0.15 kg / ton, kwaye iziphene ze-pinhole zawa nge-80%. Inkampani iqikelela ukonga ngonyaka ngaphezulu kwe-RMB 20 yezigidi ngenxa yokuncipha kwenkunkuma kunye neendleko ezisezantsi zokucokisa.

Kwicandelo leeprofayili zoyilo, umvelisi omkhulu waseTshayina usebenzise i-Optifine ukujongana nokuncamathela okulambathayo kwengubo okubangelwa ziinkozo ezirhabaxa. I-avareji yobungakanani beenkozo zancitshiswa ukusuka kwi-150 μm ukuya ngaphantsi kwe-50 μm, ukwandisa ukunamathela kokugquma ngama-30% kunye nokunyusa imveliso yemveliso ukusuka kwi-85% ukuya kwi-98%. Ngogcino lweendleko ze-RMB 120 ngetoni nganye, ifem yonga ngaphezulu kwe-RMB 12 yezigidi ngonyaka kwimveliso yeetoni ezili-100,000.

Olu phononongo lwehlabathi jikelele lugxininisa kwisigqibo esinye: Isisulungesi se-MQP esikhulu sokuziinkozo singaphezulu kwe-labhoratri yokuqamba izinto ezintsha-sisisombululo semizi-mveliso esivuthiweyo esingqinwe kumazwekazi onke. Ukusuka eMzantsi Afrika ukuya eYurophu, kuMntla Melika ukuya eTshayina, uthotho lwe-Optifine luye lwaba sisiseko sezikhulu zemizi-mveliso ezifana ne-Sapa, i-Novelis, kunye ne-Hydro, ukuseka umgangatho omtsha: gxila ekusebenzeni kakuhle, hayi nje idosi.

Ukusukela ngo-2024, ngaphezulu kwe-200 yeeprosesa ze-aluminiyam kwihlabathi jikelele ziye zamkela itekhnoloji ye-MQP, ngokudibeneyo yonga ngaphezulu kwe-100,000 yeetoni ze-Al-Ti-B kunye nokucutha ukukhutshwa kwekhabhoni malunga neetoni ezingama-500,000. La manani abonisa kungekuphela nje iinzuzo zoqoqosho kodwa namagalelo amakhulu kwimveliso ezinzileyo.

V. Ukujonga Phambili: Ukusukela kwiNtsha yoBuchule ukuya kwiNguquko ye-Ecosystem

Xa iteknoloji idlula imida yokusebenza, impembelelo yayo idla ngokudlulela ngaphaya kwemveliso ngokwayo-ukubuyisela kwakhona inkqubo yendalo yonke yoshishino. Ukunyuka kwabasulungekisi bengqolowa abakhulu be-MQP ngumzekelo walo mgaqo. Njengoko uchungechunge lwe-Optifine luqhubeka nokuvela kunye nokwahluka, impembelelo yalo yokuguqula iyanda ukusuka kwiinkqubo zemveliso ukuya kumacandelo aphezulu kunye namazantsi ekhonkco lexabiso.

Ngokobuchwephesha, ubambiswano lophando lwe-MQP-njengelo kunye neDyunivesithi yaseBrunel-lubeke ibhenchmark yentsebenziswano kwi-industry-academia. Umsebenzi wabo wenze imodeli yomjikelo opheleleyo "wophando olusisiseko-uphuhliso lwesicelo-ushishino." Njengoko isayensi yezinto eziphathekayo kunye nobuchwepheshe be-atomic-scale imaging iqhubela phambili, impumelelo yexesha elizayo kulawulo lwe-nano-interface kunye nobukrelekrele bokuxela kwangaphambili kunokuphucula ngakumbi ukuchaneka kunye nokuguquguquka.

Ngokwembono yesicelo, abasulungeki bengqolowa abakhulu baya kunceda kakhulu kwiimarike ze-niche. Imveliso ecocekileyo ye-Optifine502 ikhomba kwindlela yokwenza ngokwezifiso-ukulungelelanisa izisombululo kwiintlobo ezithile zemveliso (i-foil, iphepha, i-extrusions) kunye neemeko zenkqubo (i-twin-roll casting, i-semi-continuous casting). Abasulungekisi besiko baya kunceda abavelisi ukuba bakhulise imbuyekezo yezoqoqosho kwaye bakhuthaze ukwahluka, ukhuphiswano lwexabiso eliphezulu kulo lonke icandelo.

Kwixesha apho ukwenziwa kohlaza kunyanzelekile kwihlabathi jikelele, iinzuzo zokusingqongileyo kubuchwepheshe be-MQP zinyanzelekile. Ngokunciphisa ukusetyenziswa kwe-Al-Ti-B, izisulungesi zengqolowa eziphezulu zinciphisa ukusetyenziswa kwamandla kunye nokukhutshwa. Kwangaxeshanye, umgangatho wemveliso ophuculweyo uthetha inkcitho encinci. Njengoko umkhondo wekhabhoni usiba uxhaphake ngakumbi, ukusebenzisa izisulungesi zengqolowa eziphezulu kunokuba yimfuneko kwizatifikethi kunye nokufikelela kwimarike-ukukhawulezisa inguqu yekhabhoni ephantsi yeshishini.

E-China, itekhnoloji ye-MQP ibonelela ngenkxaso ebalulekileyo yokuphucula ishishini lasekhaya le-aluminiyam. Ngaphandle kokuba ingoyena mvelisi mkhulu kwihlabathi, iChina isenayo indawo yokukhula kumacandelo akwisiphelo esiphakamileyo njenge-aerospace kunye nemoto. Ngokuhambelana okuphuculweyo kunye nokonga kweendleko, i-Optifine inceda iinkampani zaseTshayina zoyise imiqobo yobugcisa kunye nokuphucula ukukhuphisana kwehlabathi. Ngokulandelayo, intsebenziswano ne-MQP inokukhuthaza ukusungulwa kwezinto zasekhaya, ukukhuthaza umjikelo olungileyo "wentshayelelo-ukufakwa kwakhona."

Ixesha lokuposa: Jul-26-2025