Ngokunyuka kolwazi lokukhuselwa kwendalo, ukuphuhliswa kunye nokukhuthaza amandla amatsha emhlabeni jikelele kuye kwenza ukukhuthazwa kunye nokusetyenziswa kwezithuthi zamandla kusondele. Kwangaxeshanye, iimfuno zophuhliso olukhaphukhaphu lwezixhobo zeemoto, ukusetyenziswa okukhuselekileyo kweealloyi ze-aluminium, kunye nomgangatho wabo womphezulu, ubungakanani kunye neempawu zoomatshini ziba phezulu nangaphezulu. Ukuthatha i-EV ngesisindo sesithuthi se-1.6t njengomzekelo, i-aluminium alloy material malunga ne-450kg, ibalwa malunga ne-30%. Iziphene ezingaphezulu ezibonakalayo kwinkqubo yokuvelisa i-extrusion, ngokukodwa ingxaki yengqolowa enqabileyo kwindawo yangaphakathi nangaphandle, ichaphazela kakhulu inkqubela yokuveliswa kweeprofayili ze-aluminium kwaye ibe yingxaki yokuphuhliswa kwesicelo sabo.

Kwiiprofayili ezikhutshiweyo, uyilo kunye nokuveliswa kokufa kwe-extrusion kubaluleke kakhulu, ngoko uphando kunye nophuhliso lokufa kweeprofayili ze-aluminium ze-EV lubalulekile. Ukucebisa izisombululo zenzululwazi kunye nezinengqiqo zokufa kunokuphucula ngakumbi isantya esifanelekileyo kunye nemveliso ye-extrusion yeeprofayili ze-aluminium ze-EV ukuhlangabezana nemfuno yemarike.

Imigangatho yeMveliso ye-1

(1) Izinto eziphathekayo, ukunyangwa kwendawo kunye ne-anti-corrosion yamacandelo kunye namacandelo aya kuhambelana nemimiselo echaphazelekayo ye-ETS-01-007 "IiMfuno zeTechnical for Aluminium Alloy Profile Parts" kunye ne-ETS-01-006 "IiMfuno zeTechnical for Anodic Oxidation Surface Treatment".

(2) Unyango oluphezulu: I-Anodic oxidation, umphezulu akufanele ube neenkozo ezinqabileyo.

(3) Umphezulu wamacandelo awuvumelekanga ukuba ube neziphene ezifana nokuqhekeka kunye nemibimbi. Amalungu awavumelekanga ukuba angcoliseke emva kwe-oxidation.

(4) Izinto ezivinjiweyo zemveliso zihlangabezana neemfuno ze-Q / JL J160001-2017 "Iimfuno zezinto eziBaliwe kunye neziThintelweyo kwiiNdawo zeeMoto kunye neZixhobo".

(5) Iimfuno zokusebenza komatshini: amandla okuqina ≥ 210 MPa, amandla okuvelisa ≥ 180 MPa, ukunyusa emva kokuphuka kwe-A50 ≥ 8%.

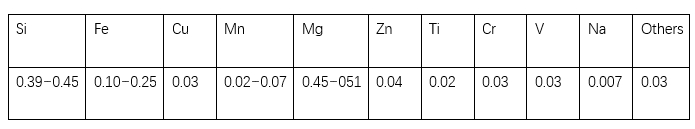

(6) Iimfuno zokwakhiwa kwe-aluminium alloy kwizithuthi zamandla amatsha ziboniswe kwiThebhile 1.

2 Ukuphucula kunye nohlalutyo oluthelekisayo lwesakhiwo sokufa kwe-extrusion Ukunciphisa amandla amakhulu kwenzeka

(1) Isisombululo semveli 1: oko kukuthi, ukuphucula i-design die extrusion yangaphambili, njengoko kubonisiwe kwi-Figure 2. Ngokombono woyilo oluqhelekileyo, njengoko kubonisiwe lutolo kumfanekiso, indawo yembambo ephakathi kunye ne-sublingual drainage position icutshungulwa, i-drainages ephezulu kunye nezantsi i-20 ° kwelinye icala, kunye nokuphakama kwe-drainage H15 mm i-riten inxalenye ye-riten isetyenziselwa ukubonelela nge-molluminum. I-sublingual imela engenanto idluliselwa kwi-angle echanekileyo, kwaye i-aluminium etyhidiweyo ihlala kwikona, ekulula ukuvelisa iindawo ezifileyo kunye ne-aluminium slag. Emva kwemveliso, iqinisekiswa nge-oxidation ukuba umphezulu uthandeka kakhulu kwiingxaki zenkozo ezirhabaxa.

Ukongezwa okuphambili kulandelayo kwenziwa kwinkqubo yokwenziwa kokungunda ngokwesiko:

a. Ngokusekelwe kulo ngundo, sazama ukwandisa ukunikezelwa kwe-aluminium kwiimbambo ngokutya.

b. Ngokwesiseko sobunzulu bokuqala, ubunzulu bomese obungenanto bunzulu, oko kukuthi, i-5mm yongezwa kwi-15mm yokuqala;

c. Ububanzi beblade engenanto engaphantsi kweelwimi yandiswa nge-2mm ngokusekelwe kwi-14mm yokuqala. Umfanekiso wangempela emva kokulungiswa uboniswe kuMfanekiso 3.

Iziphumo zokuqinisekisa zibonisa ukuba emva kokuphuculwa kwezi zintathu zingasentla, iziphene zengqolowa ezirhabaxa zisekhona kwiiprofayili emva konyango lwe-oxidation kwaye azikasonjululwa ngokufanelekileyo. Oku kubonisa ukuba isicwangciso sokuqala sokuphucula asikwazi ukuhlangabezana neemfuno zemveliso ye-aluminium alloy materials for EVs.

(2) INkqubo eNtsha yesi-2 yacetywa ngokusekwe kuphuculo lwangaphambili. Uyilo lokungunda lweNkqubo eNtsha yesi-2 luboniswe kuMfanekiso 4. Ngokomgaqo "wokunyibilika kwesinyithi" kunye "nomthetho wokunganyangeki", iindawo eziphuculweyo zemoto zithatha isicwangciso soyilo "somngxuma ovulekileyo". Isikhundla sombambo sidlala indima kwimpembelelo ethe ngqo kunye nokunciphisa ukuxhathisa ukuxhathisa; indawo yokutya yenzelwe ukuba "i-pot cover-shaped-shaped" kwaye indawo yebhulorho icutshungulwa ibe yintlobo ye-amplitude, injongo kukunciphisa ukuxhathisa ukukhuhlana, ukuphucula ukudibanisa, kunye nokunciphisa uxinzelelo lwe-extrusion; ibhuloho ifakwe ngokusemandleni ukukhusela ingxaki yeenkozo ezinqabileyo ezantsi kwebhulorho, kunye nobubanzi bomese ongenanto phantsi kolwimi lwebhulorho ephantsi ≤3mm; Umahluko wenyathelo phakathi kwebhanti yokusebenza kunye nebhanti esezantsi yokusebenza yi-≤1.0mm; ummese ongenanto phantsi kolwimi oluphezulu lokufa luhamba kakuhle kwaye luguqulelwe ngokulinganayo, ngaphandle kokushiya umqobo wokuhamba, kwaye umngxuma owenziweyo ubethelwa ngokuthe ngqo ngangokunokwenzeka; ibhanti elisebenzayo phakathi kweentloko ezimbini kwimbambo yangaphakathi ephakathi lifutshane kangangoko kunokwenzeka, ngokuqhelekileyo lithatha ixabiso le-1.5 ukuya kuma-2 ubukhulu bodonga; i-drainage groove inenguqu egudileyo ukuhlangabezana nemfuno yamanzi aneleyo e-aluminiyam yesinyithi equkuqelayo emngxunyeni, ebonisa imeko edibeneyo, kwaye ingashiyi indawo efileyo nakweyiphi na indawo (imela engenanto emva kwedayiti ephezulu ayidluli kwi-2 ukuya kwi-2.5mm). Ukuthelekiswa kwesakhiwo sokufa kwe-extrusion ngaphambi nangemva kokuphuculwa kuboniswe kwi-Figure 5.

(3) Nika ingqalelo ekuphuculweni kweenkcukacha zokucubungula. Isikhundla sebhulorho siphuculwe kwaye siqhagamshelwe ngokutyibilikayo, amabhanti asebenzayo aphezulu nasezantsi athambileyo, ukuxhathisa kwe-deformation kuyancipha, kwaye ukuhamba kwesinyithi kuphuculwe ukunciphisa ukuguqulwa kokungalingani. Iyakwazi ukucinezela ngempumelelo iingxaki ezinje ngeenkozo ezirhabaxa kunye nokuwelda, ngaloo ndlela iqinisekisa ukuba indawo yokukhutshwa kwembambo kunye nesantya seengcambu zebhulorho zilungelelaniswa kunye nezinye iindawo, kwaye ngokufanelekileyo nangobunzululwazi zicinezela umphezulu iingxaki ezifana nokuwelda okuziinkozo kumphezulu weprofayile ye-aluminium. Uthelekiso ngaphambi nangemva kokuphuculwa kokungunda kwamanzi kuboniswe kuMfanekiso 6.

3 Inkqubo yokukhupha

Kwi-6063-T6 i-aluminium alloy ye-EVs, umlinganiselo we-extrusion we-difa yokuhlukana ubalwa ukuba ube ngu-20-80, kwaye umlinganiselo we-extrusion wale nto ye-aluminium kumatshini we-1800t yi-23, ehlangabezana neemfuno zentsebenzo yemveliso yomatshini. Inkqubo ye-extrusion iboniswe kwiThebhile 2.

Itheyibhile 2 Inkqubo yokuvelisa i-Aluminiyam yeeprofayili zokuxhoma iipakethi zebhetri entsha ye-EV

Nika ingqalelo kula manqaku alandelayo xa ukhupha:

(1) Akuvumelekanga ukutshisa iimbumba kwisithando somlilo esinye, ngaphandle koko iqondo lokushisa lokubumba liya kuba lingalingani kwaye i-crystallization iya kwenzeka ngokulula.

(2) Ukuba ukuvala okungaqhelekanga kwenzeka ngexesha lenkqubo yokukhupha, ixesha lokuvala akufanele lidlule imizuzu emi-3, ngaphandle koko isikhunta kufuneka sisuswe.

(3) Akuvumelekanga ukubuyela kwiziko lokufudumeza kwaye emva koko ukhuphe ngokuthe ngqo emva kokudilizwa.

4. Amanyathelo okulungisa umngundo kunye nokusebenza kwawo

Emva kokulungiswa kokungunda okuninzi kunye nokuphuculwa kovavanyo lokungunda, isicwangciso esilandelayo sokulungiswa kokungunda siyacetywa.

(1) Yenza ulungiso lokuqala kunye nohlengahlengiso kubumba lokuqala:

① Zama ukutshonisa ibhulorho kangangoko, kwaye ububanzi bomzantsi webhulorho kufuneka bube ≤3mm;

② Umahluko wesinyathelo phakathi kwebhanti esebenzayo yentloko kunye nebhanti yokusebenza yesikhunta esisezantsi kufuneka sibe ≤1.0mm;

③ Musa ukushiya ibloko yokuhamba;

④ Ibhanti elisebenzayo phakathi kweentloko ezimbini zamadoda kwiimbambo zangaphakathi kufuneka libe lifutshane ngokusemandleni, kwaye inguqu ye-drainage groove kufuneka ihambe kakuhle, ibe nkulu kwaye igudileyo ngokusemandleni;

⑤ Ibhanti yokusebenza yesikhunta esisezantsi kufuneka ibe mfutshane kangangoko;

⑥ Akukho ndawo ifileyo kufuneka ishiywe nakweyiphi na indawo (imela engenanto yangasemva mayingabi ngaphezu kwe-2mm);

⑦ Lungisa isikhunta esiphezulu ngeenkozo ezinqabileyo kwi-cavity yangaphakathi, ukunciphisa ibhande elisebenzayo le-mold ephantsi kwaye udibanise ibloko lokuhamba, okanye ungenayo i-blood block kunye nokunciphisa ibhande elisebenzayo le-mold ephantsi.

(2) Ngokusekwe kuhlengahlengiso olongezelelweyo lokungunda kunye nokuphuculwa kokungunda okungentla, uhlengahlengiso lokungunda lulandelayo lwenziwa:

① Ukuphelisa iindawo ezifileyo zeentloko ezimbini zamadoda;

② Khulula ibloko yokuhamba;

③ Nciphisa umahluko wobude phakathi kwentloko kunye neendawo ezisebenzayo zokufa;

④ Nciphisa indawo yokusebenza esezantsi.

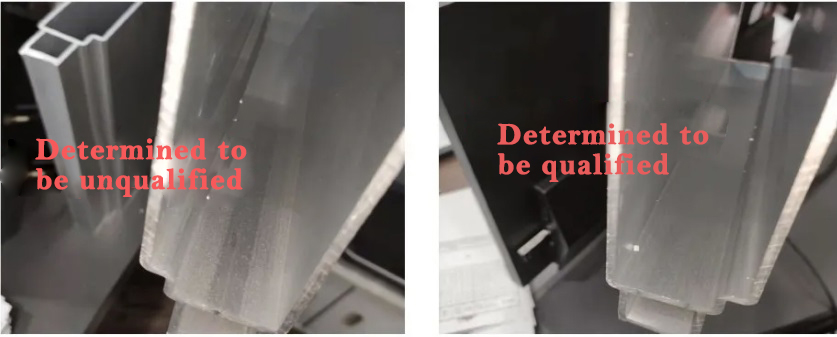

(3) Emva kokuba isikhunta silungisiwe kwaye siphuculwe, umgangatho womgangatho wemveliso egqityiweyo ufikelela kwindawo efanelekileyo, kunye nomgangatho oqaqambileyo kwaye akukho zinkozo ezinqabileyo, ezisombulula ngokufanelekileyo iingxaki zeenkozo ezinqabileyo, i-welding kunye nezinye iziphene ezikhoyo kumphezulu weeprofayili ze-aluminium ze-EVs.

(4) Umthamo we-extrusion unyuke ukusuka kwi-5 t / d yokuqala ukuya kwi-15 t / d, iphucula kakhulu ukusebenza kakuhle kwemveliso.

5 Isiphelo

Ngokuphucula ngokuphindaphindiweyo kunye nokuphucula i-mold yasekuqaleni, ingxaki enkulu enxulumene nokutya okuziinkozo kumphezulu kunye ne-welding yeeprofayili ze-aluminium kwii-EVs zasonjululwa ngokupheleleyo.

(1) Ikhonkco elibuthathaka lokungunda kwasekuqaleni, umgca wokuma kwembambo oluphakathi, lalungiswa ngokufanelekileyo. Ngokususa imimandla efileyo yeentloko ezimbini, ukuthambisa ibhloko yokuqukuqela, ukunciphisa umahluko wobude phakathi kwentloko kunye nendawo yokusebenza esezantsi, kunye nokunciphisa indawo yokusebenza ephantsi, iziphene zomphezulu we-6063 we-aluminium alloy esetyenziswe kolu hlobo lwemoto, njengeenkozo ezirhabaxa kunye ne-welding, zoyiswa ngempumelelo.

(2) Umthamo we-extrusion unyuke ukusuka kwi-5 t / d ukuya kwi-15 t / d, iphucula kakhulu ukusebenza kakuhle kwemveliso.

(3) Le meko iphumeleleyo yoyilo kunye nokuveliswa kwe-extrusion die imele kwaye ibhekisela kwimveliso yeeprofayili ezifanayo kwaye ifanele ukukhuthazwa.

Ixesha lokuposa: Nov-16-2024